含BN相变微胶囊导热硅脂的制备及性能毕业论文

2020-05-26 20:24:22

摘 要

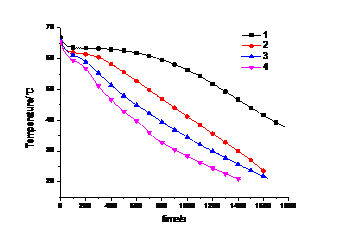

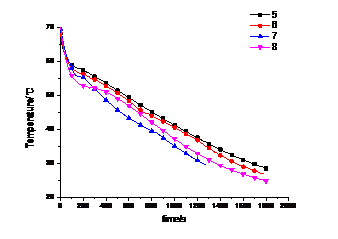

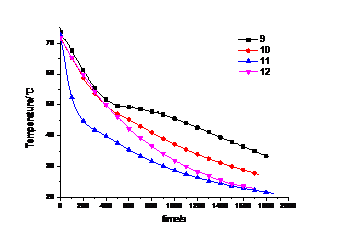

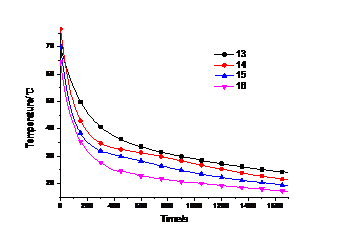

为了解决LED 灯的散热问题,本文提出在基础导热硅脂中通过添加超细BN粉和多相变点石蜡微胶囊材料的研究思路,开发具有优异导热、吸热性能的导热硅脂产品。本文根据LED的工作温度及工作环境,选择相变点分别为25℃、50℃和64℃左右的混合石蜡为相变微胶囊的芯材,采用微乳液聚合法,以苯乙烯/甲基丙烯酸作为壁材,研究了乳化剂种类、浓度、聚合时间、反应体系pH值等对聚合反应体系的影响,并利用SEM、TEM、FTIR、DSC等测试方法对相变微胶囊材料的特征参数进行了表征与分析。最后,以导热硅脂作为高分子载体,研究了超细BN粉的平均粒径、不同粒径BN混合及超细BN粉/多相变微胶囊的复配等对导热硅脂导热性能的影响,并通过LED灯温度测试平台测试其实际应用效果。获得如下主要结论:

(1)添加油相5wt.%的Span85为乳化剂,聚合体系pH值为4,聚合反应时间为300min,可制备不同相变点的微胶囊。石蜡和苯乙烯在聚合成微胶囊后,仍保持各自的结构组成不变,实现了包裹;不同相变点的微胶囊在外观和形貌上差别较小。

(2)单一粒径BN粉填充时,随添加量的增加,三种粒径制出的导热硅脂导热系数均先增大后减小;两种粒径BN复合配比时,当320nmBN:1μmBN=0.55:0.45时导热系数最高可达1.387W/m.K;三种粒径BN复合配比时,当320nm:1μm:8μm=0.45:0.385:0.165时导热系数最大,为1.429W/m.K。

(3)最佳BN粉配比情况下,较优填充工艺为:添加20wt%超细BN粉和4wt%相变微胶囊,超细BN粉平均粒径配比为320nm:1μm:8μm=0.45:0.385:0.165。

(4)LED温度测试平台测试表明,与只含超细BN粉导热硅脂相比,添加相变微胶囊的导热硅脂的散热效果优于不含相变微胶囊的导热硅脂,且在25℃、50℃和64℃等相变点附近吸收了较多的热量,使升温曲线较为平缓,有利于设备的正常运行和延长设备使用寿命。

关键词:导热硅脂 超细BN粉 多相变点微胶囊 制备 传热性能

ABSTRACT

To slove the heat problem of LED, Superfine BN powders and multiphase transformation point paraffin microcapsules material were chosen added to thermal grease for intention of developing thermal paste products with excellent thermal conductivity and endothermic performance in this paper. According to the working environment of the LED lamp and heating characteristics, choose Phase change microcapsules as the core material of mixed paraffin whose phase transition point were 25 ℃, 50 ℃ and 64 ℃. According to microemulsion polymerization method, choosing styrene and methacrylic acid as the wall material, the influence of type and concentration of emulsifier, polymerization time, Polymerization system and pH value on the process of Phase change microcapsule preparation were systematically studied, and its shape, size, and latent heat were analyzed by means of SEM, TEM, FTIR, DSC and so on. Finally, the effects of BN size, filling volume, different ratio of particle size, superfine BN powders and complex compound of multiphase microcapsules on the thermal conductivity of thermal paste, and its actual application effect was tested by LED lamp temperature test platform. The main results are as follows:

(1) When adding 5wt.% oil phase Span85 as emulsifier and the pH value of polymerization system is 4 and the reaction time reached 300 min, there is no significant difference in the shape and morphology of microcapsules with different transformation point, indicating that the process is suitable for making multi-phase change microcapsules.

(2) When filled with single particle size BN powders, the thermal conductivity of the thermal grease with three kinds of particle size are increased first and then decreased with the increase of added amount. When BN with two kinds of particle size is composite proportion, when 320nmBN:1μmBN equal to 0.55:0.45, the thermal conductivity is up to the tallest 1.387W/m.K. When BN with three kinds of particle

size is composite proportion, when 320nm:1μm:8μm equal to 0.45:0.385:0.165, the thermal conductivity is up to the tallest 1.429W/m.K。

(3) Under the best composite proportion condition, good filling process is that adding 20wt.% superfine BN powders and 4wt.% phase change microcapsule. An average particle size ratio of superfine BN powders is 320nm: 1μm: 8μm which is equal to 0.45: 0.385: 0.165.

(4) Based on the test results in LED temperature test platform, compared to the thermal grease only containing superfine BN powders, cooling effect of the thermal grease added with the phase change microcapsule is much better than the thermal grease without the phase change microcapsule. When the temperature is about 25 ℃, 50 ℃ and 64 ℃, it absorbed more heat making warming curve more gentle than before that it is helpful to prolong equipment life.

Keywords: Thermal Grease; Superfine BN Powders; Multiphase change Microcapsule; Preparation; heat transfer property

目 录

摘 要 I

ABSTRACT II

第一章 绪 论 1

1.1 前沿 1

1.2 导热硅脂 2

1.2.1 导热硅脂简介 2

1.2.2 导热硅脂的导热机理及组成 2

1.2.3 填充材料对导热硅脂性能的影响 3

1.2.4 导热硅脂的应用 5

1.3 相变微胶囊及其应用 5

1.3.1 相变微胶囊简介 5

1.3.2 芯材的选择 6

1.3.3 壁材的选择 6

1.3.4 相变微胶囊的制备方法 7

1.3.5 相变微胶囊的应用 8

第二章 研究目标、内容及方法 9

2.1 研究目标 9

2.2 研究内容 9

2.2.1 基体选择 9

2.2.2 填料选择 9

2.2.3 研究内容 9

2.3 相变微胶囊的制备及表征 10

2.3.1 不同相变点石蜡混合物的制备 10

2.3.2 相变微胶囊的制备 11

2.3.3 相变微胶囊的表征与性能测试 11

2.4 含超细BN粉/多相变微胶囊导热硅脂的制备及性能表征 12

2.4.1 含超细BN粉/多相变微胶囊导热硅脂的制备 12

2.4.2 含超细BN/多相变微胶囊导热硅脂的性能表征 12

2.5 实验药品及仪器 13

第三章 石蜡相变微胶囊制备工艺研究 16

3.1 前言 16

3.2 不同石蜡配比芯材的降温曲线 16

3.3 相变微胶囊的制备工艺研究 19

3.3.1 不同乳化剂及其浓度的选择 19

3.3.2 聚合时间对相变微胶囊产率的影响 22

3.3.3 反应体系pH值对相变微胶囊形貌的影响 23

3.3.4 固体石蜡相变微胶囊的表征 25

3.4 混合石蜡微胶囊的制备及表征 28

3.4.1 TEM分析 28

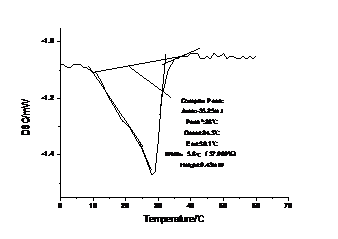

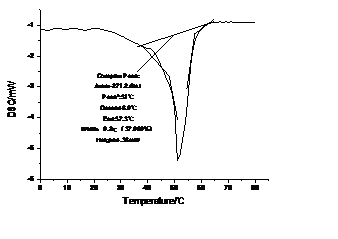

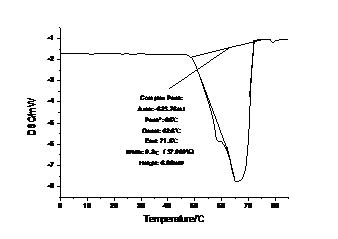

3.4.2 DSC测试 29

3.5 本章小结 30

第四章 含超细BN粉/多相变点微胶囊导热硅脂性能研究 32

4.1 前言 32

4.2 超细BN粉粒径对硅脂导热系数的影响 32

4.3 两种粒径BN粉体复配对导热硅脂导热系数的影响 33

4.3.1 320nmBN与1μmBN复配 34

4.3.2 320nm与8μmBN复配 35

4.3.3 1μm BN与8μm BN复配 36

4.4 三粒径BN粉体复配对导热硅脂导热系数的影响 38

4.4.1 A组实验结果 38

4.4.2 B组实验结果 39

4.4.3 C组实验结果 40

4.4.4 三粒径复配导热硅脂导热系数对比分析 41

4.5 相变微胶囊的加入对导热硅脂导热系数的影响 42

4.6 导热硅脂在LED灯温度测试平台测试结果 44

4.7 本章小结 45

第五章 结论与展望 47

5.1 结论 47

5.2 存在问题及展望 48

参考文献 49

致谢 50

第一章 绪 论

1.1 前言

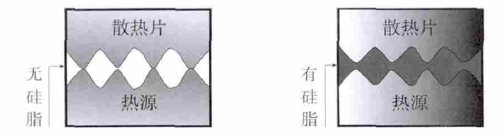

随着社会的进步,电子产品的发展越来越趋向于密集化和微型化;然而,电子产品的密集化和微型化对散热效率的要求也更高[1]。由于热聚焦现象,电子产品在工作时电能转化为热能会产生大量的热,如果其散热效率不好,很容易造成电子产品局部高温,从而直接影响到产品的使用寿命。导热硅脂是以硅油为基材,以大量的导热填充材料为辅材组成的导热介质材料。导热硅脂可以填充电子产品发热部位和散热部位之间的空隙,由于它具有很强的导热能力,可以及时将产生的热量释放出去,防止电子产品工作过程中发生局部高温,从而可以提高电子产品的工作效率及寿命。导热硅脂作为导热介质材料使用,能够满足电子产品的密集化和微型化要求,其性能会直接影响到电子产品的散热效果。图1-1导热硅脂的应用示意图[2]。 图 1-1导热硅脂的应用示意图

图 1-1导热硅脂的应用示意图

窗体顶端

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。