掺合料对粉煤灰-矿渣体系耐酸性的影响毕业论文

2020-06-17 21:46:13

摘 要

碱激发粉煤灰-矿渣因为其优良的性能(早期强度大,流动性好和凝结时间可控)得到广泛的研究。但是,在碱激发粉煤灰矿渣的耐酸性方面,特别是耐硫酸腐蚀性问题还没有得到系统的研究。

硅酸钠激发不同配比的粉煤灰矿渣(70%矿渣/30%粉煤灰,50%矿渣/50%粉煤灰,30%矿渣/70%粉煤灰),同时添加不同的分子筛(0‰,1‰和5‰),然后测试硬化体养护至28d抗压强度和之后完全浸没在3%硫酸溶液中腐蚀后的抗压强度。研究结果表明:分子筛的掺入对前期强度影响不大,但是养护至28d,随着分子筛的掺量的增加,抗压强度逐渐下降。酸浸28d后,样品抗压强度全部下降,除了碱激发30%矿渣/70%粉煤灰体系之外,分子筛掺入1‰ 和5‰的样品下降后的强度基本小于0‰掺量样品。

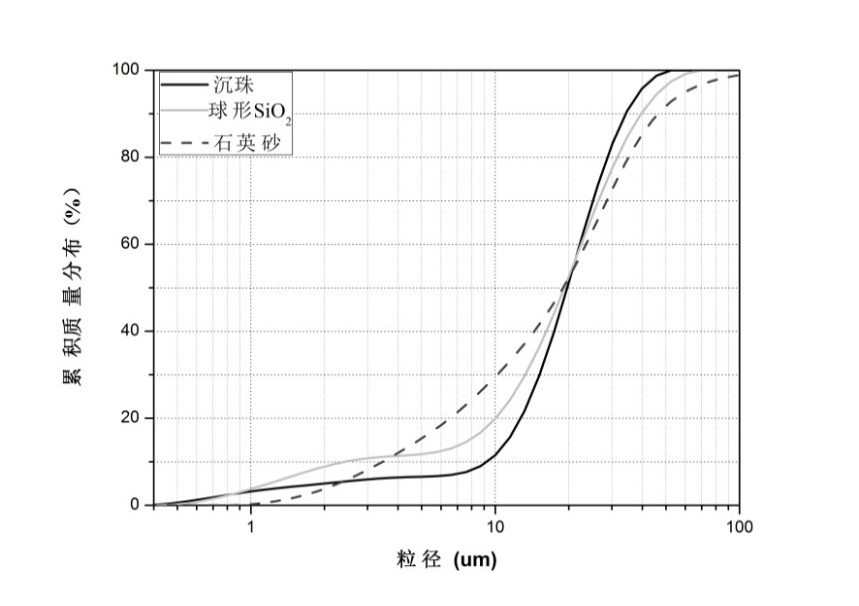

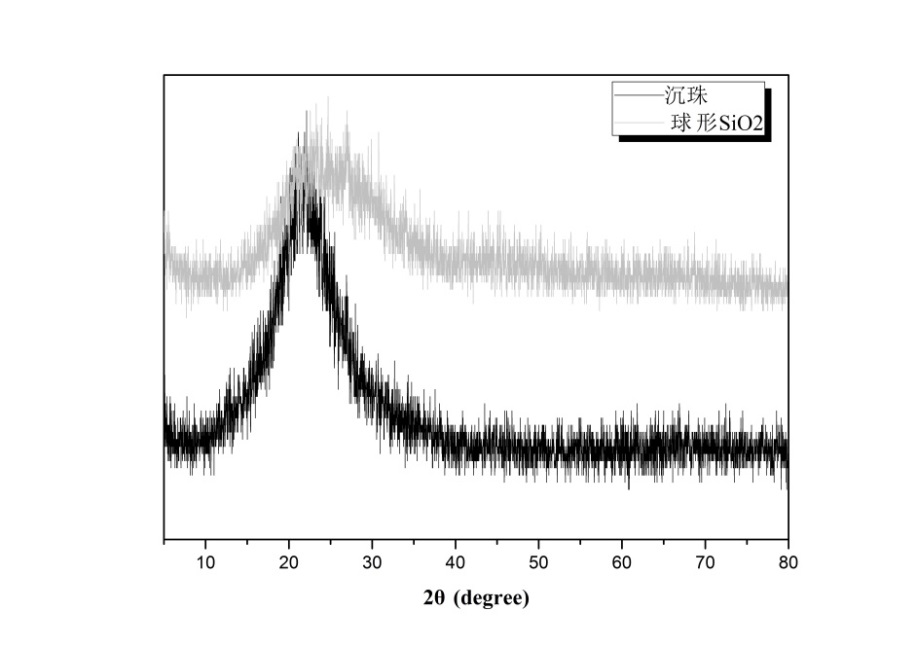

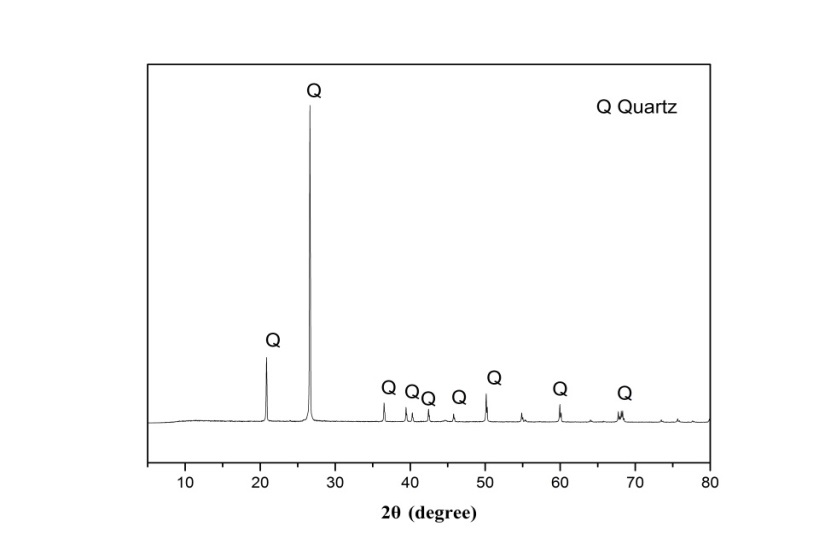

硅酸钠激发30%矿渣/70%粉煤灰,测试同时掺入5%,15%和30%的不同硅质材料(球形SiO2,沉珠和石英砂)在不同养护温度下(20℃和80℃)的抗压强度。之后将样品浸泡在3%硫酸溶液7d和30d,测试样品的凝结时间和抗压强度。实验结果表明:20℃养护时,随着硅质材料掺入增加样品的抗压强度逐渐降低。就凝结时间而言,不同掺量球形SiO2,沉珠会导致凝结时间延长,但是5%石英砂会导致终凝时间缩短。80℃时,相比0%掺量,5%掺量硅质材料都会增加抗压强度,且增长幅度最大的为石英砂,达到37.4%。经过30d酸浸养护,样品的强度出现下降,但是5%掺量的硅质材料掺量抗压强度还是大于0%掺量的强度。此外,30d的酸浸并没有使得样品的外观出现明显的剥落,这是与20℃养护的样品不一样的,特别是30%样品出现明显的表面剥落。

关键词:碱激发材料 硅质材料 分子筛 粉煤灰 矿渣 酸腐蚀

Effect of mineral admixture on acid resistance of

alkali-activated fly ash - slag

Abstract

Alkali activated fly ash/slag has been extensively studied for its excellent properties (early strength, good fluidity and controllable setting time). However, the problem of acid resistance of alkali activated fly ash/slag, especially sulfuric acid corrosion resistance, has not been systematically studied.

Sodium silicate activated different proportions of fly ash/slag (70% slag/30% fly ash, 50% slag /50%fly ash, 30% slag/70% fly ash), simultaneously adding different molecular sieves (0 ‰, 1 ‰ and 5 ‰). The compressive strength of the hardened pastes was tested up to 28d, and then completely immersed in 3% sulfuric acid solution, after that, the compressive strength after corrosion was also tested. The results show that the incorporation of molecular sieves has little effect on the initial strength, but the compressive strength decreases gradually with the addition of molecular sieves at 28d. After the acid leaching of 28d, the compressive strength of the samples all decreased, and the strength of the samples dropped with 1 ‰ and 5‰ adding molecular sieves was basically less than 0 ‰, except for the alkali activated 30% slag /70% fly ash system.

The compressive strength of sodium silicate activated 30% slag/70% fly ash, with 5%, 15% and 30% of different siliceous materials (spherical SiO2, bead and quartz sand) adding under different curing temperatures (20℃ and 80℃), were tested. After that, the samples were immersed in 3% sulfuric acid solution and compressive strength up to 30d and appearance at 30d were presented. Meanwhile, the setting time of samples at 20℃ was tested. The experimental results show that the compressive strength of the sample decreases gradually with the addition of siliceous material at 20℃ curing. In terms of setting time, different amounts of spherical SiO2 and beads will lead to a longer setting time, but 5% quartz sand will lead to a shorter final setting time. At 80℃, adding 5% silica material will increase the compressive strength, compared to 0% dosage, and the largest growth is quartz sand, reaching 37.4%. After 30d acid leaching curing, the strength of the sample decreased, but with siliceous material 5%, the compressive strength is still greater than 0% of the strength of the amount. In addition, the acid leaching of 30d did not make the appearance of the sample apparent spalling, which was different from the sample of 20 degree curing, especially the obvious exfoliation of the 30% samples.

Key words: Alkali activated materials;Siliceous material;zeolite;Fly ash;Slag; Acid corrosion.

目录

摘要 I

Abstract I

第一章 绪论 1

1.1 矿渣 1

1.2 粉煤灰 2

1.3 碱激发胶凝材料 2

1.4 碱激发胶凝材料抗化学侵蚀性 3

1.5 研究内容 6

1.6 技术路线 6

第二章 实验部分 7

2.1 实验原料 7

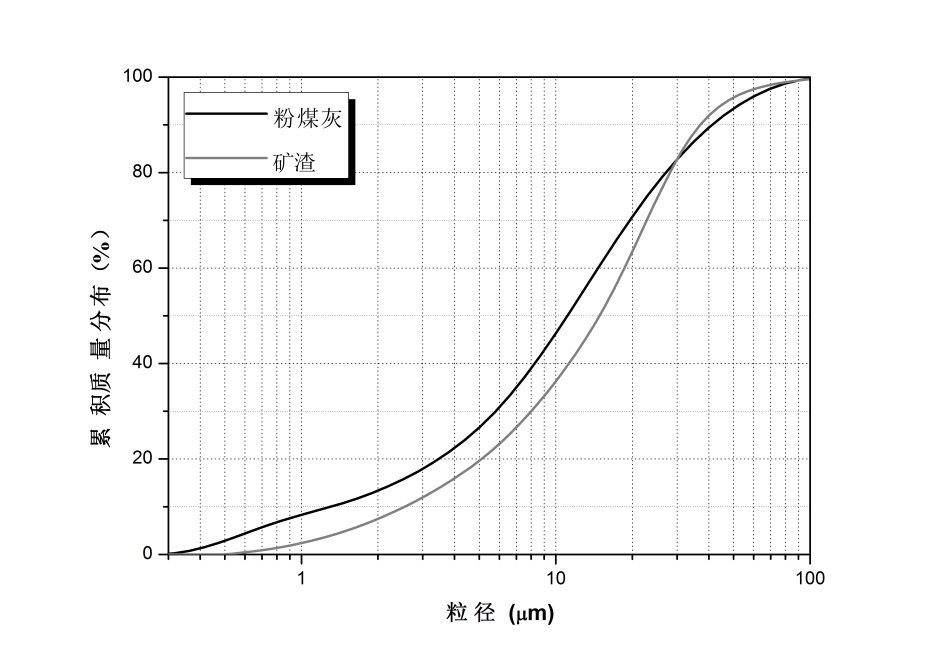

2.1.1 矿渣 7

2.1.2 粉煤灰 8

2.1.3 ZSM-5型沸石分子筛 9

2.1.4 沉珠 石英粉 球形SiO2 9

2.1.5 水玻璃和氢氧化钠 9

2.2 实验设备 11

2.3 实验方法 11

2.3.1 水玻璃溶液和氢氧化钠的制备方法 11

2.3.2 配制3%浓H2SO4溶液 12

2.3.3 浆体的制备方法 12

2.4 测试方法 13

2.4.2 抗压强度测定方法 14

第三章 实验结果与讨论 15

3.1 ZSM-5分子筛掺量对抗压强度影响 15

3.2 硅质材料研究 17

3.2.1 凝结时间 17

3.2.2 外观检查 18

3.3.3 抗压强度 18

第四章 结论与展望 24

4.1 结论 24

4.2 展望 24

参考文献 25

致谢 27

第一章 绪论

1.1 矿渣

史才军[1]等人研究发现,在炼铁的过程中,把铁矿石、助熔剂、作为燃料的焦炭和废铁一起加入高炉中,石灰石分解成CaO和CO2,CaO是助熔剂,可以脱硫和除去其他杂质,进一步形成矿渣,被铁矿石和焦炭带入的Al2O3、MgO、SiO2和石灰也会形成矿渣。矿渣的主要化学成分是SiO2、Al2O3和CaO等,有些矿渣含有少量的TiO2、BaO等。

玻璃体矿渣是二维SiO4四面体框架结构,其成分可以分为网络形成体、网络改变体和中间体。Si和P是网络形成体,其含量越高,玻璃体聚合度越大。Na 、K 和Ca2 是玻璃体矿渣中的网络改变体,两性金属Al和Mg是典型的中间体。实际生产中得到的矿渣是由玻璃相和结晶相组成的复合体,玻璃相和晶体相的比值越高,矿渣水化活性越高。网络形成剂SiO2越多,网络调整剂(如CaO)连接的[SiO4]4-四面体多,玻璃结构的稳定性增大,水化活性减小。玻璃网络的聚合度用平均桥氧数来衡量,桥氧数越小,则[SiO4]4-、[AlO4]5-链的聚合度越低,矿渣的水化活性提高。由于[AlO4]5-四面体的键强低于[SiO4]4-,在聚合度相同的情况下,[AlO4]5-增多,网络稳定性降低,矿渣水化活性提高。一般来说,矿渣在水中不具备水硬性,即矿渣的胶凝能力不能自动发挥出来,但通过使用激发剂后可以形成胶凝性物质,从而具有水硬性。

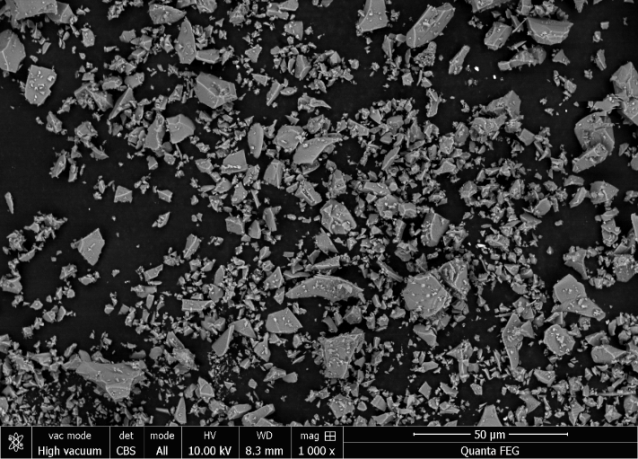

矿渣可以根据高炉矿渣的碱度分类,碱度是指化学成分中的碱性氧化物与酸性氧化物的质量分数的比值,当碱度gt;1时为碱性矿渣;当碱度=1时为中性矿渣;当碱度lt;1时为酸性矿渣。矿渣替换水泥胶砂中部分水泥时,随着替代量逐渐增加,胶砂3d强度渐渐减小,当矿渣替代水泥混凝土中的水泥量≤50%时,混凝土与钢筋的粘结强度会提高,但矿渣替代水泥量≥60%时强度会降低。路阳[2]等研究得出,由于矿渣自身具有良好的活性,在激发剂存在的条件下,可以改善水泥性能。将矿渣、硅酸盐水泥熟料、加入4%左右的石膏混合磨细制成矿渣硅酸盐水泥,可以显著降低水泥成本。

1.2 粉煤灰

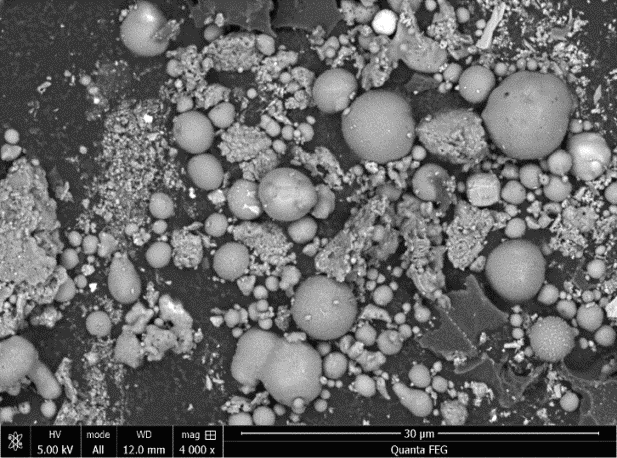

粉煤灰是一种颗粒非常细的粉状物质。钱觉时[3]指出,煤粉颗粒在较高温度下,发生一系列的物理化学变化后形成粉煤灰。首先,煤粉达到熔融状态,表面能达到最小,煤粉颗粒棱角收缩,颗粒成为球形状,这些球形颗粒在煤粉燃烧过程中产生的CO、CO2、SO2和水蒸气中漂浮,经过充分燃烧离开火焰区,快速地移动到温度较低的区域,淬灭成中空厚壁球状颗粒,可能会继续与CO、CO2、SO2和水蒸气发生二次反应聚合和解聚,这些在排出烟道过程中被特定收尘器收集下来的形状相似的粉末,即是粉煤灰。同类型煤的粉煤灰颜色越浅,表明粉煤灰颗粒越细。钱觉时[4]在电镜下观察到小颗粒粉煤灰为表面光滑的球形颗粒,较大粒径的粉煤灰形状不规则。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。