废轮胎热解机理研究毕业论文

2020-06-20 19:14:39

摘 要

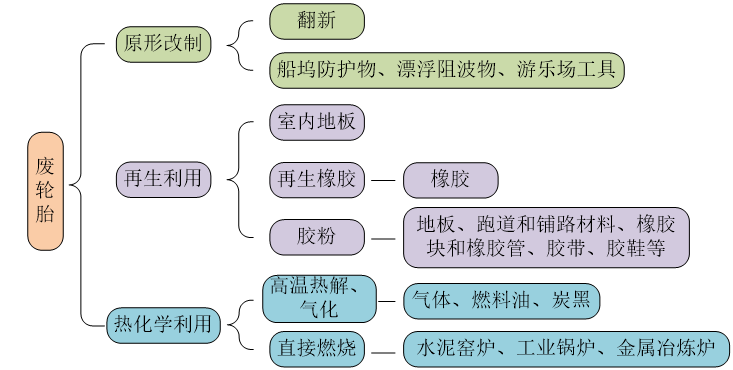

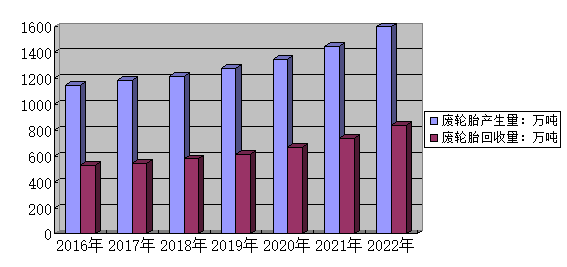

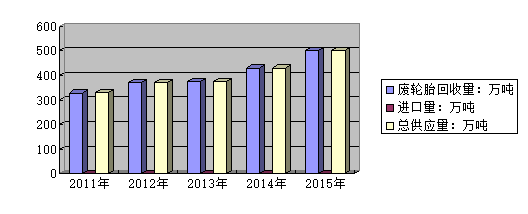

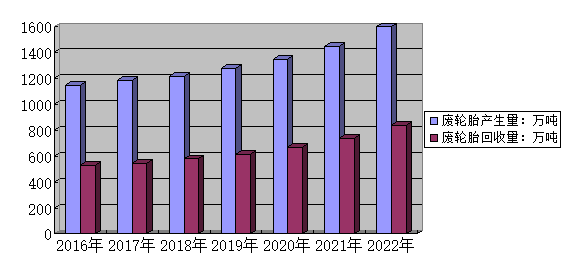

2016年,中国汽车的拥有量达2.9亿辆以上。并以年增长率10%以上的速度,快速增长。与此同时,汽车增长带来的轮胎的消耗也在成比例的提高,轮胎的废弃数量突破了每年10亿个。原形改制和再生利用,作为废轮胎常运用的回收手段,由于轮胎中橡胶的韧性较大,填充在橡胶中钢丝的刚性较强,在进行切割和冷冻等破碎预处理时,耗时耗力。而热化学处理比起其他两种方法,无需消耗能量的破碎预处理,废轮胎将直接变为能量和资源来回收,更加适合多次回收和利用。

本文以反烧式固定气化炉作为实验器材,将废轮胎与生物质进行共热。对废轮胎热解机理、过程与阶段,展开分析与研究。并改变不同的生产环境,考察其对热解的进程及产物的影响。主要的结果如下:

- 气化过程分为3个阶段,升温阶段(100℃左右),稳定产气阶段(220℃~480℃),余碳反应阶段(gt;480℃)。在26m3/h的进气流量时,在19min,32min,48min时,气化层分别移动到T2、T3和T4测温点处。

- 当改变进气流量,分别为26m3/h、28m3/h和30m3/h时,随着气体流量的增加,在产生气体中:氢气的成分比例为3.91%、4.37%和5.26%,含量上升;一氧化碳的含量上升明显,含量分别为9.9%、10.5%和12.4%;CO2含量上升,分别为14.68%、17.95%和18.71%;CH4含量变化不明显,为2.03%、1.99%和1.99%;产气量增大,分别为54.8m3/h、55.2m3/h和57.7m3/h;气化效率提高,分别为53.73%、54.63%和55.12%;气体的热值增大,分别为3.05MJ·Nm-3、3.8MJ·Nm-3和4.2MJ·Nm-3。

关键词:废轮胎 生物质 气化 反烧

Experimental study on the co-gasification of waste tire and biomass

ABSTRACT

In 2016, The number of China's automobile has more than 290 million .And the annual among grew rapidly with the rate of more than 10%. At the same time, The more cars will consume more tires.The number of abandoned tires is one billion per year.Waste tires are recovered by prototyping and recycling.Due to the greater toughness of rubber in the tire,and the rigidity of the steel wire is strong , so you need to cut and freeze it before recycling.The thermal chemical treatment compared to the other two methods, without the need for energy consumption of the broken pretreatment.Waste tires will be directly into energy and resources to recover,it more suitable for multiple recycling and use.

In this paper, the anti-burning fixed gasifier as experimental equipment, the waste tire and biomass co-thermal. Mechanism, process and stage of waste tire were analysed and researched. And change the different production environment, to examine its impact on the process of pyrolysis and products. The main results are as follows:

(1)The gasification process is divided into three stages:The heating stage (about 100℃)stable gas production stage (220℃~480℃), the residual carbon reaction stage (gt; 480℃).In the 26m3/h intake air flow,at 19min,32min,48min, the gasification layer were moved to T2,T3 and T4 temperature measurement point.

(2)When the influent air flow is changed to 26m3/h,28m3/h and 30m3/h respectively,the composition ratio of hydrogen is 3.91%, 4.37% and 5.26% with the increase of gas flow rate. The content of CH4 was increased by 2.03%, 1.99% and 1.99%. The content of carbon monoxide increased by 9.9%, 10.5% and 12.4%, and the contents of CO2 were 14.68%, 17.95% and 18.71% respectively.Gas production increased by 54.8m3/h,55.2m3/h and 57.7m3/h.The gasification efficiency increased by 53.73%, 54.63% and 55.12%.The calorific value of the gas increased by 3.05m3/h,55.2m3/h and 57.7m3/h.

Key words:Waste tire;Biomass;Gasification;Reverse Burning

目 录

摘 要 I

ABSTRACT II

第一章 绪论 1

1.1 废轮胎回收背景和未来展望 1

1.1.1 废轮胎的回收背景 1

1.1.2 未来展望 2

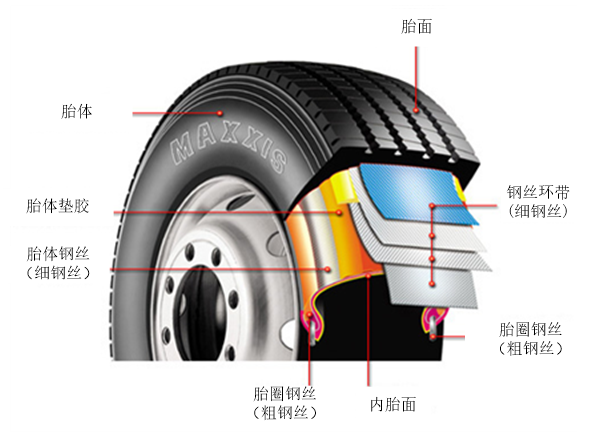

1.2 废轮胎的组成结构 5

1.3 废轮胎的热化学处理 6

1.4 生物质气化过程 7

1.4.1 生物质反应的过程 7

1.4.2 生物质反应的原理 8

1.5 废轮胎热解工艺 9

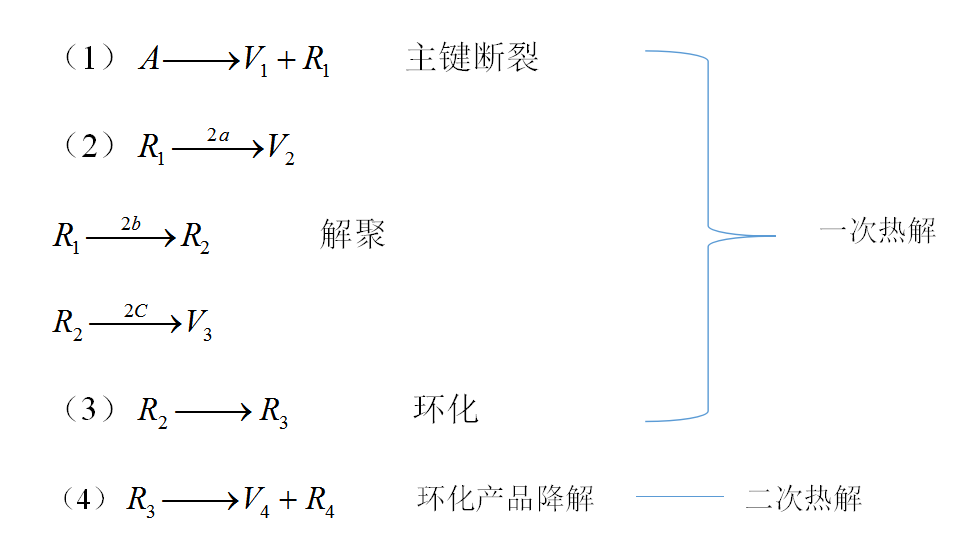

1.6 热解机理的实验研究 11

1.7本文主要研究内容 12

第二章 实验过程 13

2.1 “反烧”式气化原理 13

2.2 固定床气化炉 14

2.3 实验部分 14

2.3.1 实验原料 15

2.3.2 主要仪器 15

2.3.3 废轮胎热解实验步骤 18

2.3.3 色谱仪气体检测实验步骤 19

2.3.4 实验条件 20

2.3.5 计算步骤 20

2.4本章小结 21

第三章 实验结果与分析 22

3.1 生成物成分分析 22

3.2 “反烧”式气化炉的气化特征 25

3.3 气化效率的计算 29

3.4本章小结 29

第四章 气化系统效益分析 31

4.1气化炉计算 31

4.2 经济效益 31

4.3 盈亏平衡 33

4.4 环境效益 34

4.4 本章小结 34

第五章 结论与展望 36

5.1 结论 36

5.2 展望 36

参考文献 38

第一章 绪论

1.1 废轮胎回收背景和未来展望

1.1.1 废轮胎的回收背景

- 原型改制

原型改制不经过化学变化,通过对废旧轮胎简单的物理加工,将其变为可利用的产品[1-2]。包括原型利用和轮胎翻新两种手段[3]。

原型利用如:国内码头的护弦、人工渔礁石、鞋底及垫片的加工甚至是艺术装饰上。但随着橡胶工业的快速发展,用于原型改制的废旧轮胎价格渐渐变高,在质量和价格上都不再具有优势。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。