平头塔式起重机下支座主弦杆组焊夹具设计毕业论文

2020-06-20 19:17:58

摘 要

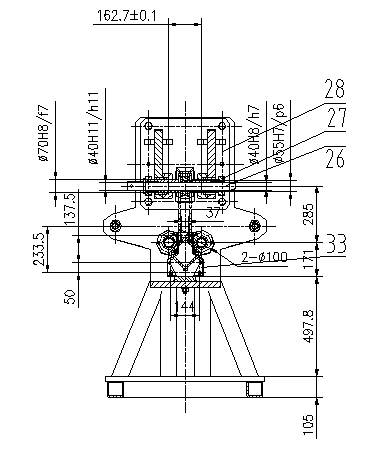

针对平头塔式起重机下支座主弦杆焊接制造,本文设计一套组焊夹具,要求对下支座主弦杆的定位方便快捷,简化焊接时的定位和夹紧操作,实现机械化,将焊接条件变为较好的平焊位置,改善劳动条件,同时也能提高焊缝的质量。

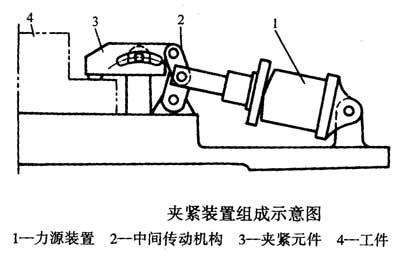

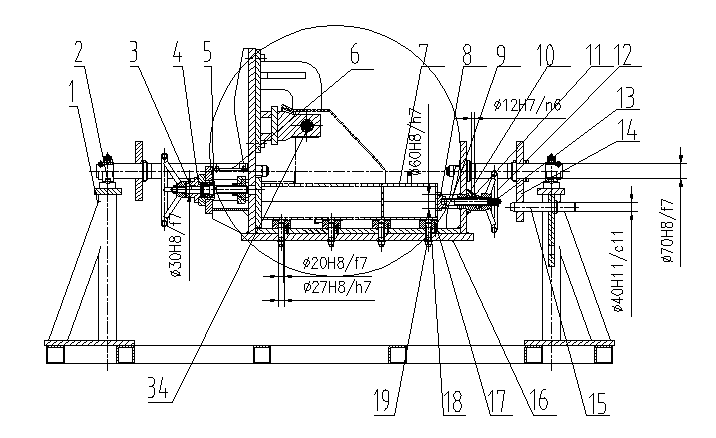

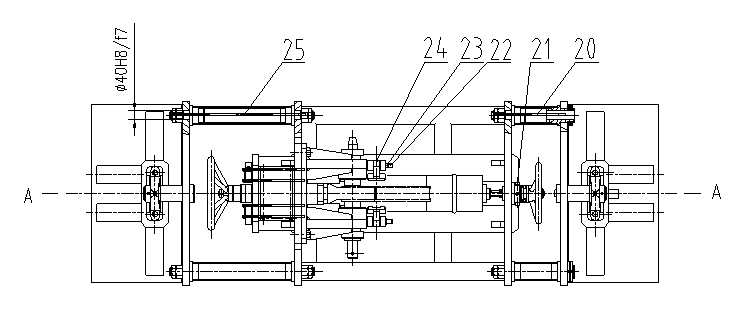

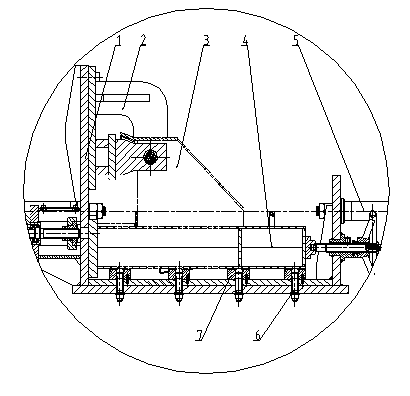

通过对平头塔式起重机主弦杆下支座结构及组焊夹具的必要性、组焊夹具的组成结构特点进行分析,然后围绕主弦杆下支座的组焊夹具设计这一核心,归纳了组焊夹具的设计过程,并且对塔机下支座主弦杆组焊夹具的设计,包括定位支座,夹具体,夹紧装置进行设计。塔式起重机下支座主弦杆组焊夹具的夹紧定位与夹紧装置是设计的重点。本文采用螺旋夹紧的方式来保证工件可靠的安装在夹具中,并通过工装翻转支架与工装支承座连接成整体实现下支座主弦杆位置变换。定位支座的设计是为了确保焊件在夹具中获得正确装配位置,通过下支座主弦杆结构的分析,设计出对应的支撑方式,减少装配误差,并考虑定位装置和夹紧方式经济性、实用性、精确性及操作方便等要求。本文旨在采用下支座组焊夹具来代替复杂的焊接操作来减轻工作量,提高生产效率及提升产品质量和生产效率。

关键词:下支座主弦杆 夹具设计 夹紧装置 工件定位

窗体顶端

Design of welding fixture for main chord of lower support under flat head tower crane

Abstract

This paper designs a set of welding fixture for the positioning of the main chord of the lower bearing, which simplifies the positioning and clamping operation of the main chord of the lower support and realizes the mechanization and welding Conditions become better flat welding position, improve working conditions, but also improve the quality of the weld.

Through the analysis of the structure of the main chord under the main chord and the necessity of the welding fixture, the composition of the welding fixture is analyzed, and then the core of the welding fixture design of the main chord under the main chord is summarized. The design process of the welding fixture is designed, and the design of the welding fixture of the main chord of the lower part of the tower is designed, including the positioning bearing, the clamping body and the clamping device. The clamping positioning and clamping device of the main chord of the lower part of the tower crane is the design focus. In this paper, the use of spiral clamping to ensure that the workpiece is reliably installed in the fixture, and through the tooling flip bracket and tooling support seat to achieve the overall realization of the next seat main chord position transformation, positioning bearing design is to ensure that the weldment Fixture to obtain the correct assembly position, through the lower bearing main chord structure analysis, design the corresponding support, reduce the assembly method, and consider the positioning device and clamping method economy, practicality, accuracy and ease of operation and other requirements The This paper aims to reduce the workload, improve productivity and improve product quality and productivity by replacing the complex welding operations.

Key Words:Crane Fixture Design Clamping Device Workpiece Positioning

This paper analyzes the necessity and feasibility of the design of the welding fixture for the lower part of the main chord of the flat tower crane.And then around the main chord under the seat of the welding fixture design of the core, through the tower crane production line, tower crane fixture structural characteristics of the analysis.The design steps and main points of the welding fixture are summarized, and the design of the welding fixture is most imortant thing,inculding locator,clip design,clamping device design,the design of locator is to ensure that the weld parts in the fixture to obtain the correct assembly of parts.Should be pre-installed with the spare parts as a post assembly parts of a base surface of the support point,it can reduce the number of locators and improve assembly accuracy.The design of the fixture is determined by calculating the clamping force of the weld angle deformation and the calculation of the clamping force to control the bending deformation of the weldment.Calculating the until length(weld) clamping force required for the deformation of the restraint angle by the formula ,and then complete the design of the fixture according to the shape and size of the weldment .

Clamping device is the most important design of this article,the design of main core is based on the group welding fixture design to replace the complex welding techniques to reduce the workload,improving production efficiency and product quality. 窗体底端

目 录

摘要........................................................Ⅰ

ABSTRACT....................................................Ⅱ

第一章 绪论..................................................1

1.1 课题背景与意义..................................................1

1.2 夹具在国内外的现状与发展........................................1

1.3夹具设计的基本原理与特点.........................................2

1.3.1 工件的定位...................................................2

1.3.2 夹紧装置的组成及其设计原则...................................3

1.3.3夹具体.......................................................4

1.4 本课题研究的内容................................................5

第二章 平头塔机下支座主弦杆组焊夹具的总体方案设计...........7

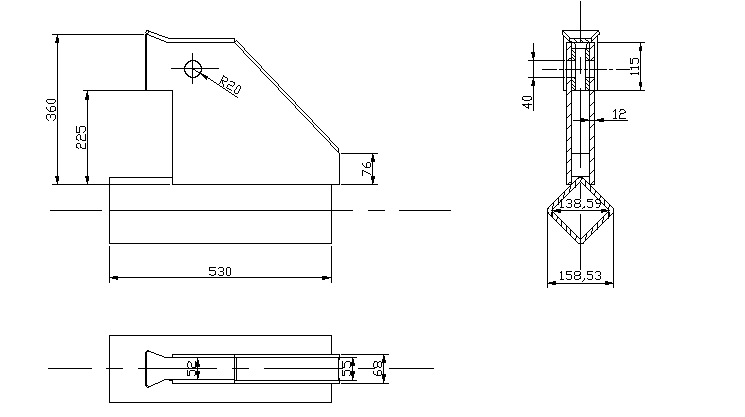

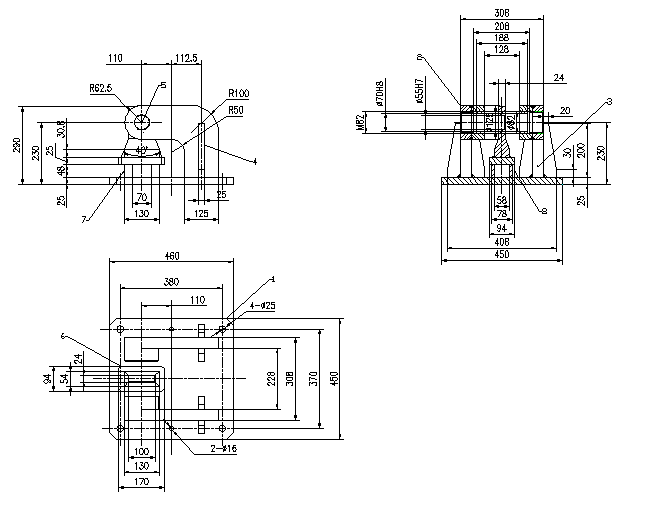

2.1 下支座材料结构及分析............................................7

2.2 下支座组焊夹具设计总体方案......................................8

2.3 夹具的定位方案.................................................11

2.4 夹具的夹紧方案.................................................13

2.5 夹具定位与夹紧的配合...........................................14

2.6 本章小结.......................................................15

第三章 平头塔机下支座主弦杆组焊夹具零部件组成及技术要求.....16

3.1 夹具体..........................................................16

3.1.1 夹具体毛胚制造方法的选择.....................................16

3.1.2 夹具体毛胚的选择.............................................16

3.2 定位座及定位元件................................................17

3.2.1 定位垫块....................................................17

3.2.2 V型块......................................................18

3.2.3 定位销......................................................18

3.2.4 定位螺套....................................................19

3.2.5 定位销轴....................................................19

3.2.6 定位套......................................................20

3.3 其余零件.......................................................21

3.3.1 手轮........................................................21

3.3.2 丝杆及丝杆导向套............................................21

3.3.3 螺杆........................................................23

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。