氯化苄类化合物生产废气的处理工艺研究毕业论文

2020-07-02 22:39:17

摘 要

氯化苄类化合物在生产工艺流程中会产生大量的有机无机混合废气, 包括各类氯化有机物、氯化氢以及氯气等。针对这种情况,现在工程上大多是采用“三级降膜水吸收 碱吸收 活性炭吸收”的传统方式来处理,但用这种工艺气相中加大大量有机物,多为原料和产品,存在资源的浪费,并且制得的副产盐酸其中含有大量有机杂质,品质很差,难有出路,另外,尾气采用活性炭吸收工艺,频繁更换、“三废”产量大、二次污染等十分严肃以及运行成本昂贵等一系列问题,成为限制企业发展的突出难题。

本论文针对以上几个问题, 拟在原有三级降膜水吸收工艺前,新增气相的有机无机分离工艺, 这种工艺不仅能高效的回收有机组分,回收的有机物产物还能循环利用,节能降耗,同时能避免副产盐酸中的大量有机杂质,大幅度提升盐酸品质,此外,还能大大延缓活性炭吸收装置更换频率,降低运行成本、削减二次污染。

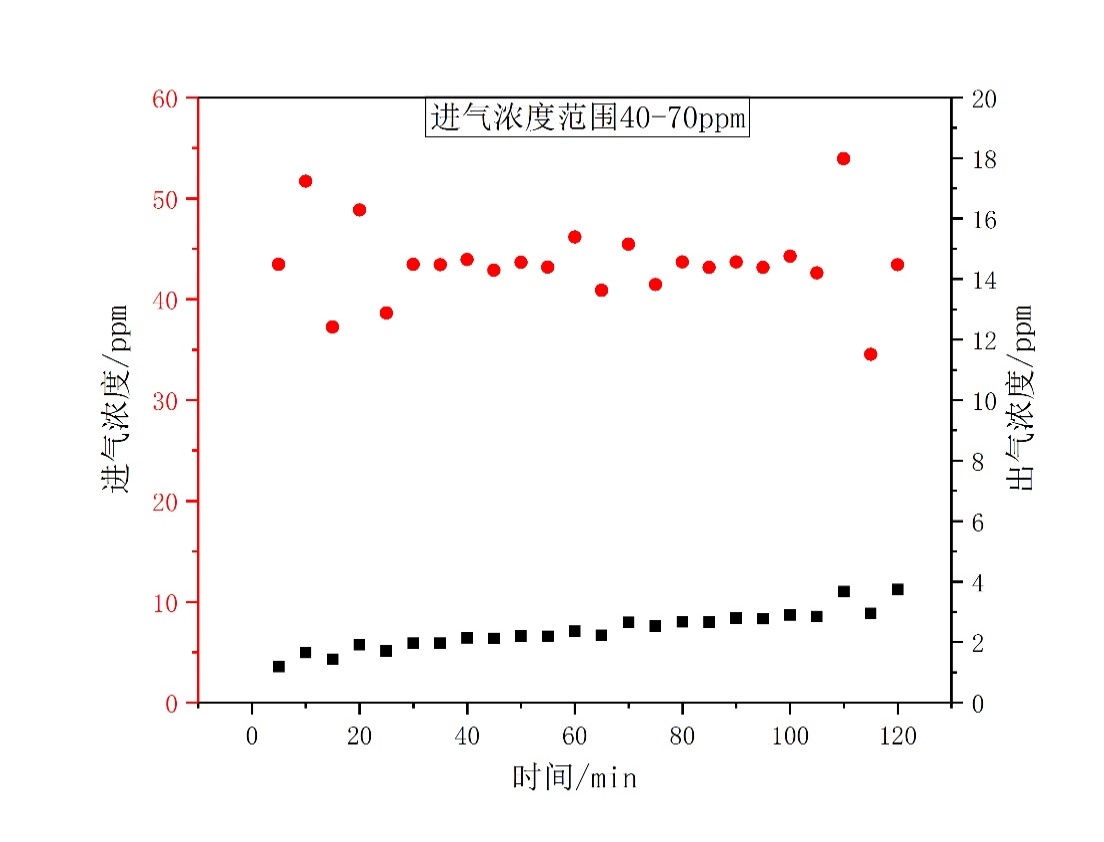

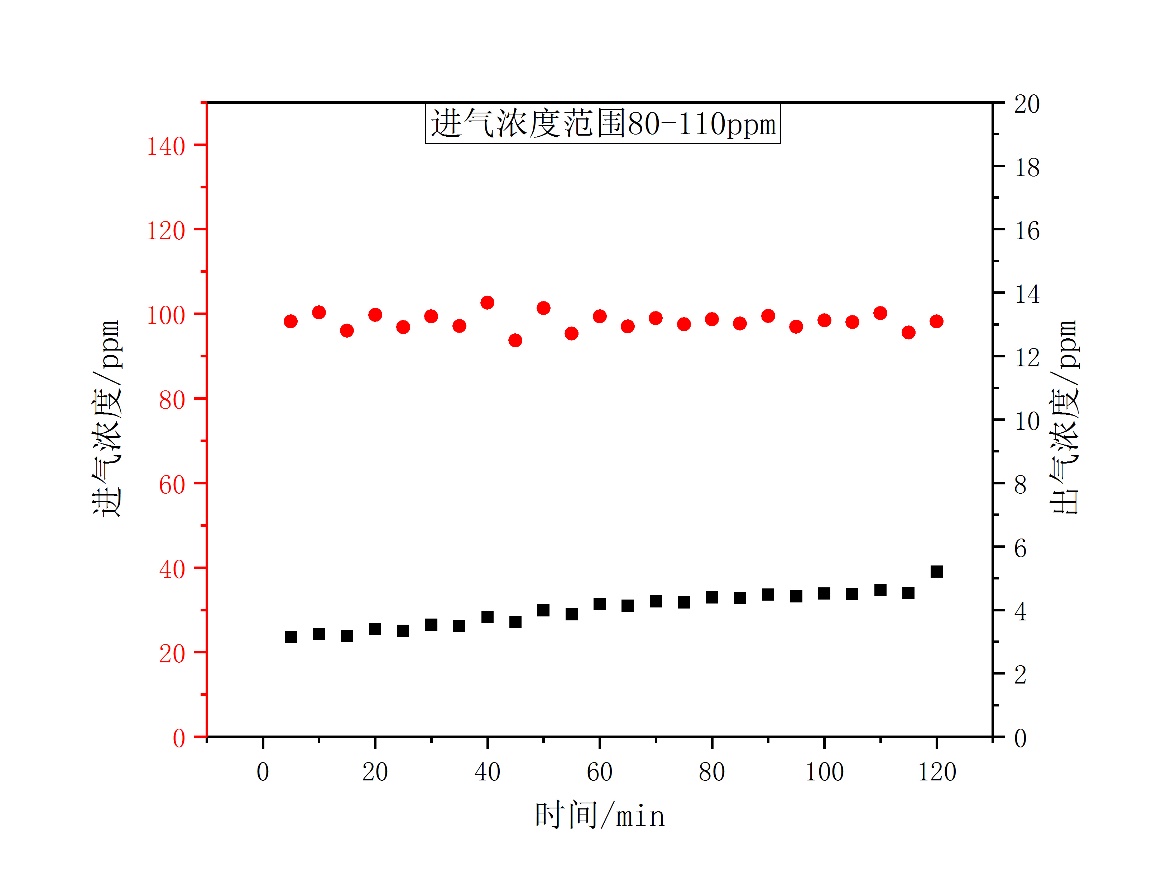

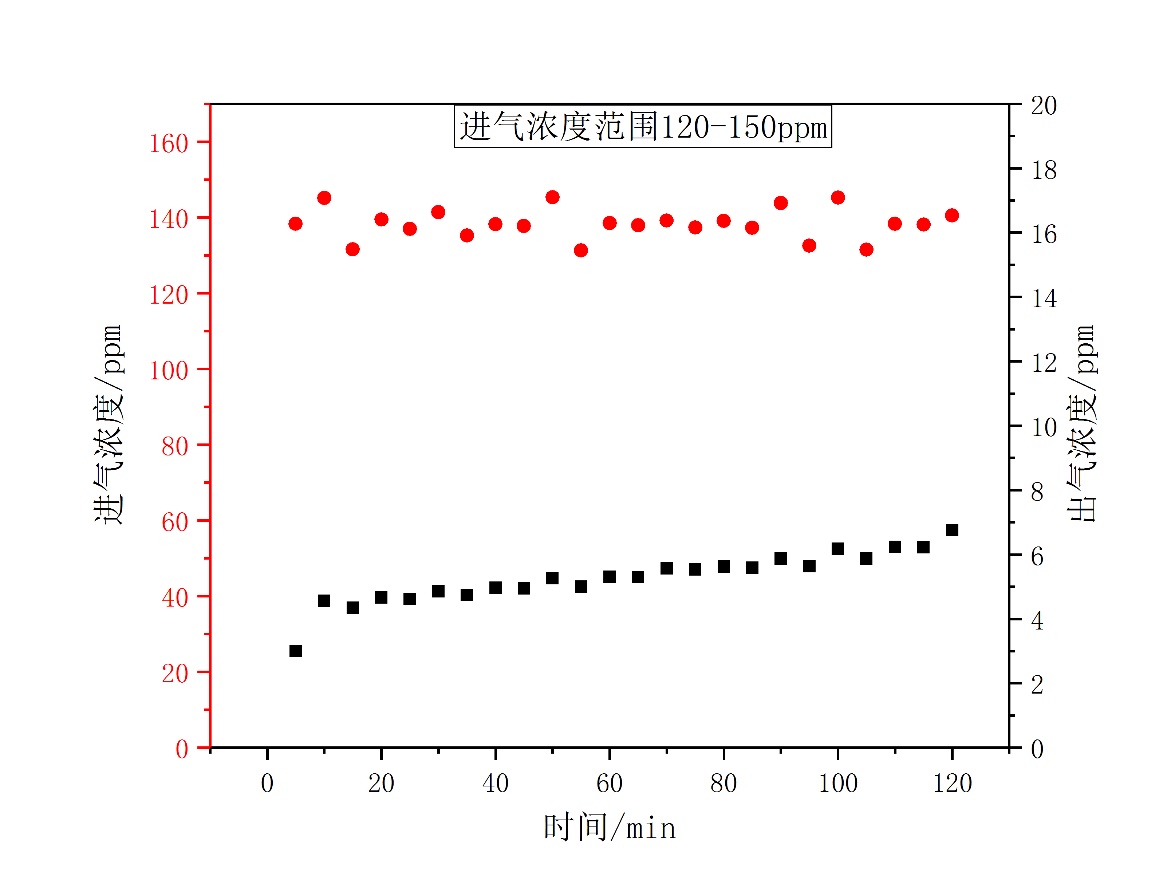

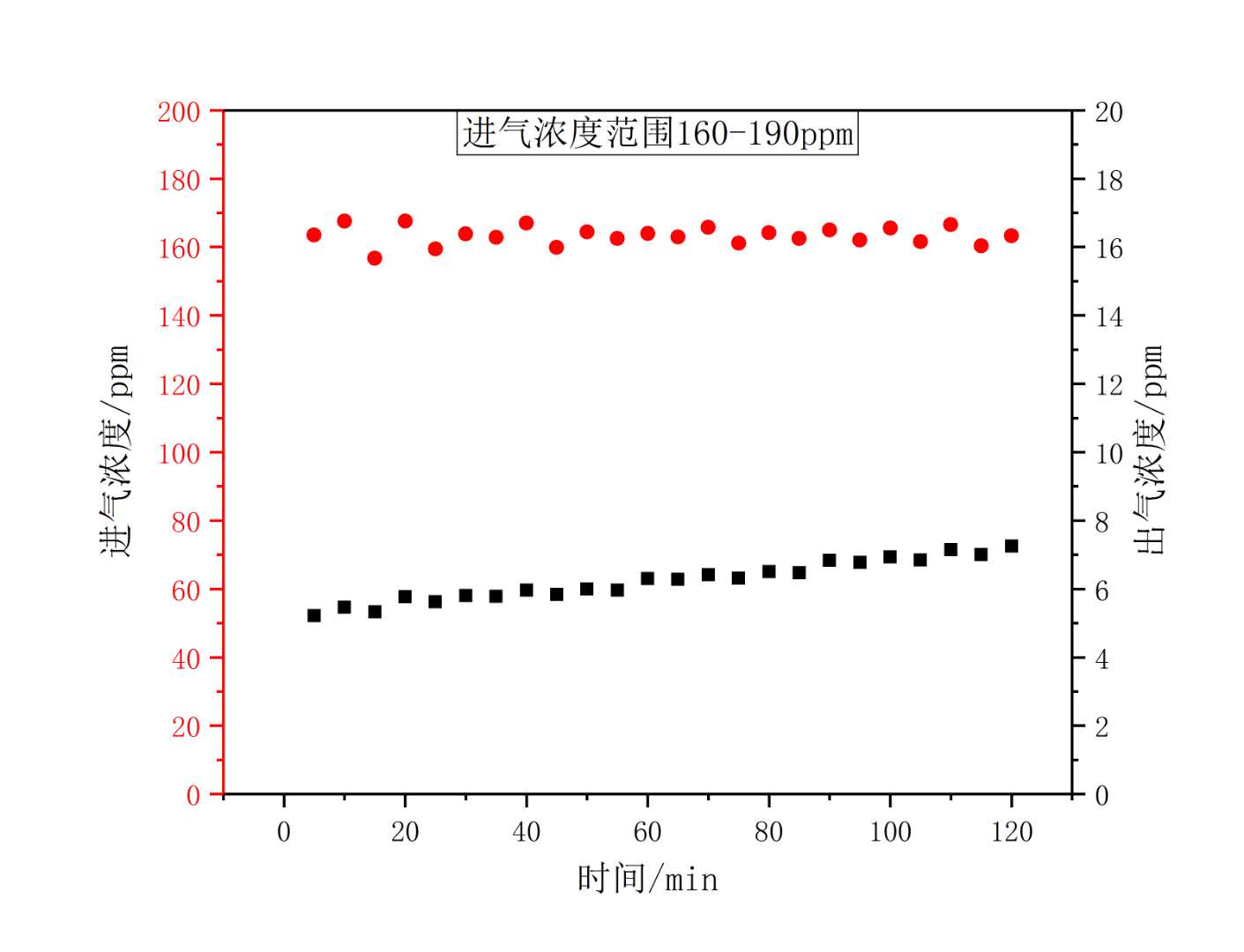

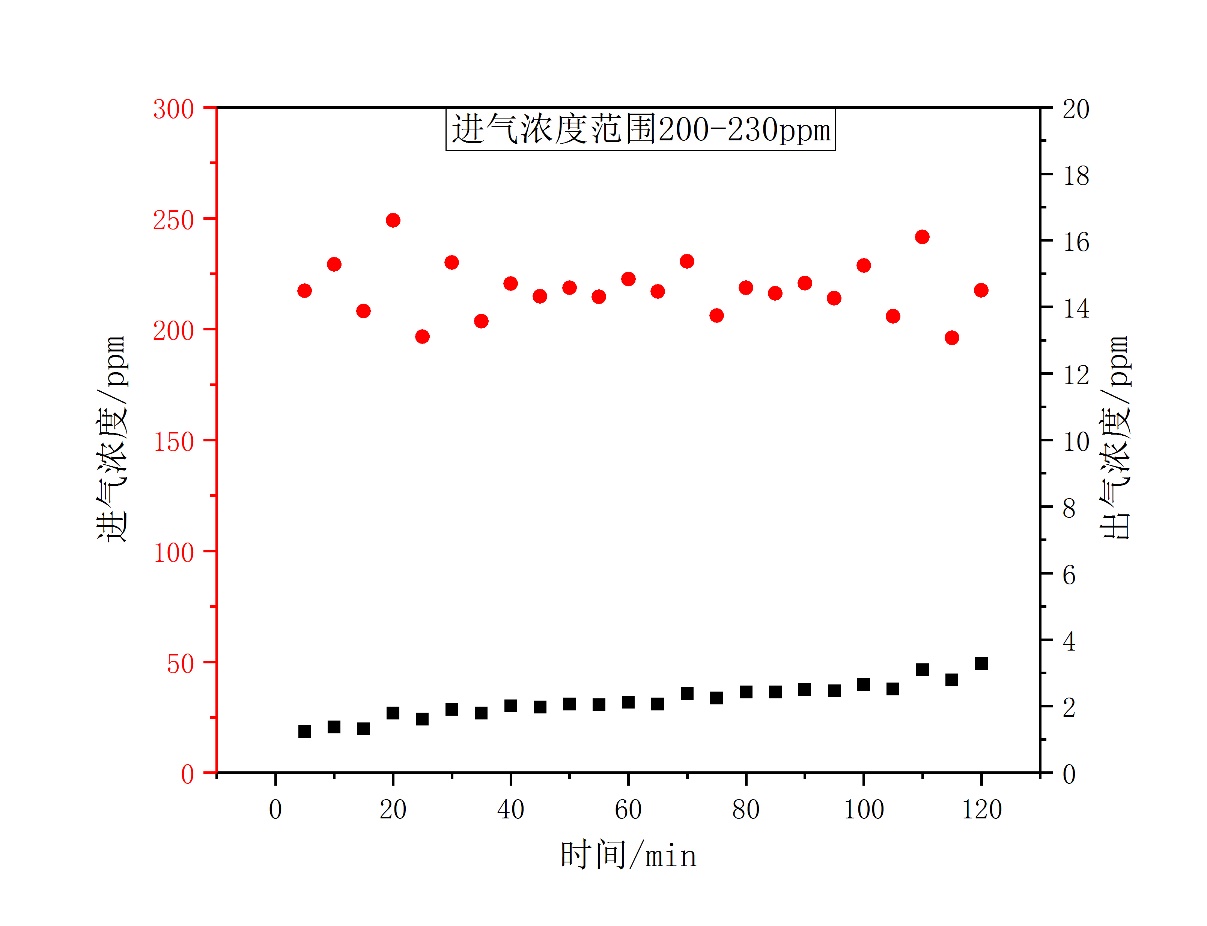

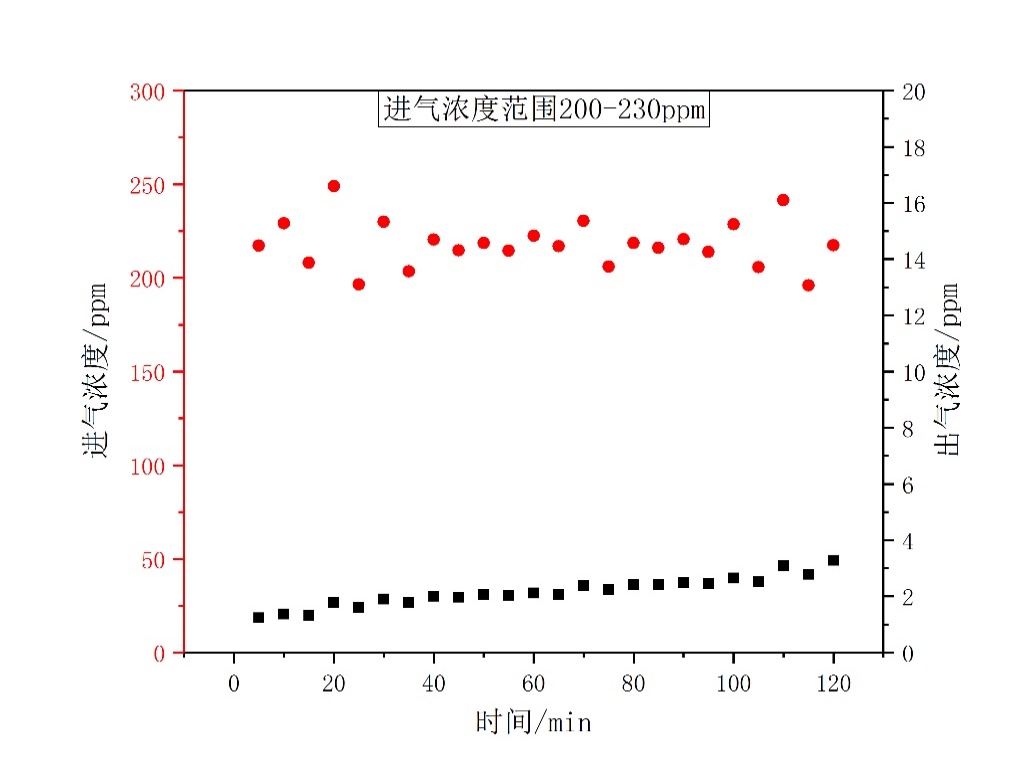

本论文研究了①混合气体的浓度、②吸收的时间、③混合气体的流量以及④捕获剂的种类这四个因素下的单因素实验,来评估这四个因素对这项新型分离工艺功效的影响,以期找出最佳的工艺条件,通过实验验证:最优的实验反应条件为:处理时间是1.5小时、有机物进气浓度范围是200-230ppm、混合气体流量:0.10 L/min、捕获剂种类:捕获剂W533。在此条件下,有机物的去除效率在95%以上,同时捕获剂W533的饱和吸收量为15.62%wt。另外,通过工艺对比,分别研究了相同条件下,未采用捕获工艺与采用捕获工艺盐酸中有机物含量,实验结果表明:采用新增捕获工艺的盐酸酸度略有下降,同时有机物浓度下降92%,品质显著提升。

关键词: 氯化苄 有机无机混合废气 HCl 资源回收

Study on Treatment Process of Benzene Chloride Compound Production Waste Gas

Abstract

Benzene chloride compounds produce a large amount of organic-inorganic mixed exhaust gas in the production process, including various types of chlorinated organic compounds, hydrogen chloride, and chlorine. In view of this situation, most of the projects are currently handled in the traditional way of “three-stage falling film water absorption amp; alkali absorptionamp;activated carbon absorption.” However, in this process, a large amount of organic substances are added to the gas phase, mostly raw materials and products. The waste of resources, and the byproduct hydrochloric acid contained therein contains a large amount of organic impurities, the quality is very poor, and it is difficult to have a way out. In addition, the tail gas adopts activated carbon adsorption technology, frequent replacement, "three wastes" production, secondary pollution, etc. are very serious and run A series of problems such as high costs have become a prominent problem that restricts the development of enterprises.

This paper aims at the above issues and proposes to add a gas-phase organic-inorganic separation process before the original three-stage falling film water absorption process. This process can not only efficiently recover organic components, but also recycle organic products. Energy-saving and consumption-reducing, at the same time can avoid a large number of organic impurities in the by-product hydrochloric acid, significantly improve the quality of hydrochloric acid, in addition, can greatly delay the replacement frequency of activated carbon absorption device, reduce operating costs and reduce secondary pollution.

In this dissertation, single factor experiments under the four factors of adsorption time, flow rate of 2 mixed gas, concentration of 3 mixed gas, and type of 4 capture agents were studied to evaluate the effectiveness of these four factors for this novel separation process. Impact, in order to find out the best process conditions, through the experimental verification: the optimal experimental reaction conditions are: processing time is 1.5 hours, organic matter intake gas concentration is about 210ppm, mixed gas flow rate: 0.10 L/min, capture agent type: Capture agent W533. Under this condition, the removal efficiency of organics was above 95%, while the saturation adsorption of capture agent A was 15.96% wt. In addition, through the process comparison, the organic content in hydrochloric acid was not used under the same conditions, and the capture process was not used. The experimental results showed that the acidity of hydrochloric acid with the new capture process did not decrease significantly, while the organic concentration decreased by 92%. Significantly improved.

Keywords: benzyl chloride; organic-inorganic mixed exhaust; HCl;resource recovery

目 录

摘 要 I

ABSTRACT II

第一章 绪论 1

1.1研究的背景 1

1.1.1氯化苄概述 1

1.1.2目前存在的氯化苄类化合物的生产工艺 2

1.2.废气产生、排放的危害及其处理 3

1.2.1VOCs气体产生、排放的危害及其处理 3

1.2.2含HCl的气体产生、排放及其处理工艺 4

1.2.3.目前处理工艺的不足之处 5

1.3本课题要解决的问题 5

1.4本课题研究的意义 5

第二章 使用的实验装置及其方法 7

2.1 实验药品和装置 7

2.2 实验流程 8

实验设计流程 8

第三章 实验结果 9

3.1 工艺实验 9

3.1.1 不同有机物进气浓度对去除效率的影响 9

3.1.2 不同吸收时间对去除效率的影响 13

3.1.3混合气体的流量对去除效率的影响 15

3.1.4捕获剂的种类对去除效率的影响 19

3.2 捕获剂的饱和吸收量 20

3.3 盐酸的酸度和TOC值 21

第四章 实验结论 22

参考文献 23

致谢 26

第一章 绪论

1.1研究的背景

1.1.1氯化苄概述

氯化苄的别称有苄基氯、氯甲苯等等,分子式通常写为C6H5CH2Cl。氯化苄在常温下是一种无色的透明液体,会挥发出一种刺鼻的刺激性气味。同时,氯化苄也是一种重要的有机中间体,在有机合成的领域应用广泛,起到很大的作用。而且在农药制药、染料、医药药品和导热载体、合成树脂以及香料等几个化工制品方向上,氯化苄类的化合物也都有广泛的应用。现在有一种光催化之后氯化的合成工艺是目前化工工业上生产氯化苄的主要工艺,这种工艺是通过使甲苯的侧链氯化,进而引发一连串的反应,反应后主要的产物有氯化苄和苄叉二氯以及苄川三氯等等,同时,取代反应大多发生在苯环上,反应后主要生成的产物有对氯甲苯、对邻氯甲苯以及其他高取代物,但是副产物主要是对氯氯苄和邻氯氯苄,杂质大致有氯化氢等气体[1-3]。

关于氯化苄的生产工艺,目前了解到以下方法:

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。