基于EDR的200Th燃料油冷却器的设计毕业论文

2020-07-11 18:04:53

摘 要

换热设备是化工、炼油、动力、能源、冶金、食品、机械、建筑工业中普遍应用的典型设备。一般换热设备在化工、炼油装置中的建设费用比例达20%~50%,因此无论从能源利用,还是从工业的投资来看,合理地选择和设计换热器,都具有重要意义。

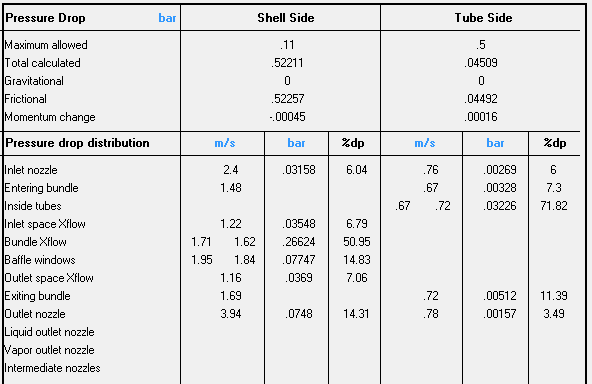

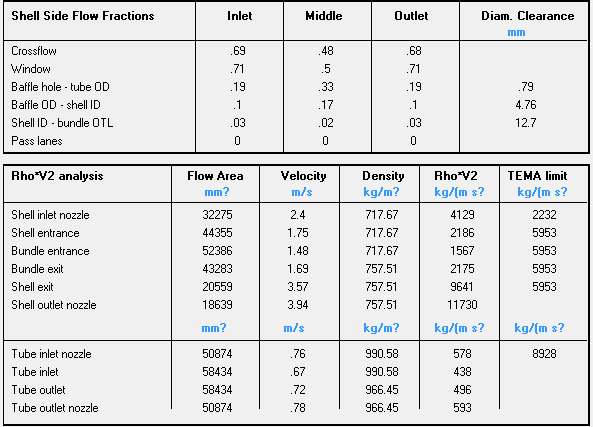

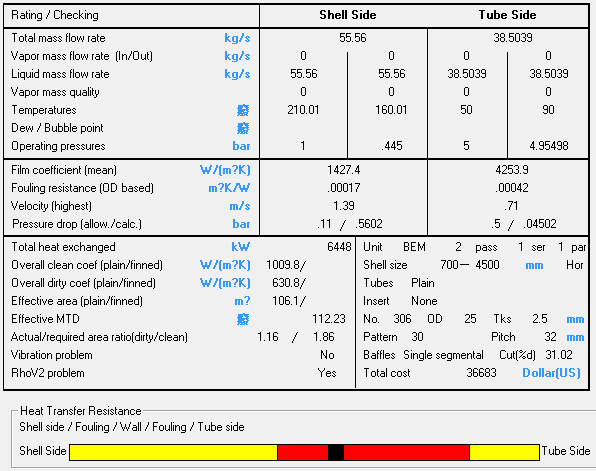

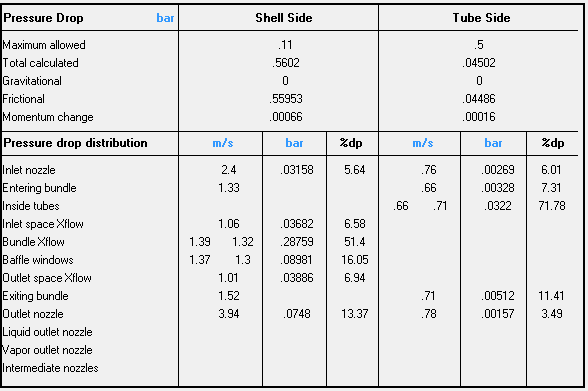

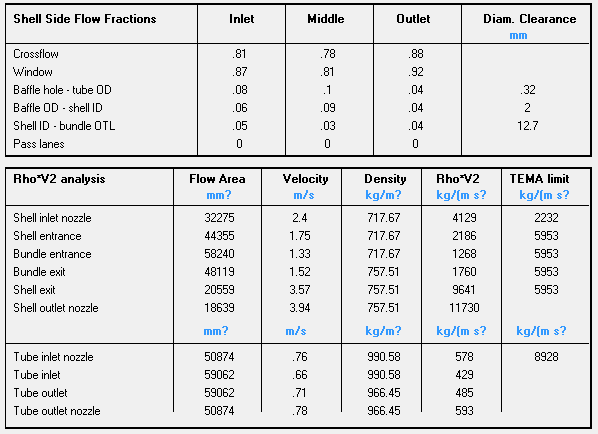

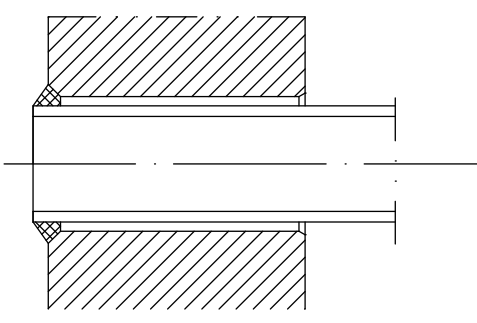

本文先简要介绍了国内外对管壳式换热器的研究状况,然后介绍了管壳换热器的设计方法。在此之上,本文选定特定参数,集合相关文献,设计了一台200t/h燃油冷却器,并用EDR软件进行辅助设计,其中包括传热计算,EDR校核,结构计算等方面的内容。本文设计的管壳式换热器,热油的进出口温度分别为250℃和180℃,工作压力为0.1MPa,冷却水的流量为138.6T/h,进出口温度分别为50℃和120℃,工作压力为0.3MPa。换热器的热负荷为6308kW,换热面积为108.2m2,换热器的类型为lt;1-2gt;型的固定管板式换热器,管长4.5m,管子内径为20mm,外径为25mm,管子根数为306根,管子的排列方式为等边三角形排列,管间距为32mm。内径为700mm,壁厚10mm。折流板为单弓形折流板,间距为380mm,圆缺率为30%。拉杆直径为16mm,一共6根。最后,本文对管壳式换热器的设计进行了总结与对未来的展望。

关键词:管壳式换热器 EDR 传热设计 结构设计

Design of 200t/h Fuel Cooler Based on EDR

Abstract

Heat exchange equipment is a typical equipment commonly used in the chemical, oil refining, power, energy, metallurgy, food, machinery, and construction industries. In general, the construction cost of heat exchange equipment in chemical and oil refinery equipment accounts for 20% to 50%. Therefore, in terms of energy use and industrial investment, the rational selection and design of heat exchangers are of great significance.

In this paper, the research status of shell-and-tube heat exchanger at home and abroad is briefly introduced. Then the design method of shell-and-tube heat exchanger is introduced. On this basis, this article selected specific parameters, collected relevant literature, designed a 200t/h fuel cooler, and used EDR software for auxiliary design, including heat transfer calculation, EDR check, structural calculation, and other aspects. Here is the result of the shell-and-tube heat exchanger designed in this paper, the inlet and outlet temperatures of hot oil are 250°C and 180°C, the working pressure is 0.1MPa, the cooling water flow is 138.6T/h, the inlet and outlet temperatures are 50°C and 120°C, respectively. The working pressure is 0.3MPa. The heat load of the heat exchanger is 6308kW, the heat exchange area is 108.2m2, the type of the heat exchanger is a fixed tube-plate heat exchanger lt;1-2gt; type, the length of the tube is 4.5m, the inner diameter of the tube is 20mm, the outer diameter is 25mm The number of tubes is 306. The tubes are arranged in an equilateral triangle with a tube spacing of 32 mm. The inner diameter is 700mm and the wall thickness is 10mm. The baffle is a single bow baffle with a spacing of 380 mm and a 30% rounding rate. Rod diameter is 16mm, a total of six. Finally, this paper summarizes the design of shell-and-tube heat exchangers and looks forward to the future.

Keywords: shell-and-tube heat exchanger;EDR ;heat transfer design;structural design

目录

摘要 Ⅰ

ABSTRACT Ⅱ

第一章 绪论 1

1.1研究背景 1

1.2国内外研究状况 1

1.2.1强化管程传热 1

1.2.2强化壳程传热 1

1.3管壳式换热器的设计 2

1.3.1传热设计 2

1.3.2结构设计 2

1.3.3优化设计 2

1.3.4利用EDR进行设计 3

第二章 传热计算 5

第三章 EDR校核分析 22

3.1初步校核 22

3.2调整优化 24

3.3设计结果 27

第四章 结构计算 28

4.1 壳体、管箱壳体及封头 28

4.2管板 29

4.3法兰 29

4.4换热管 29

4.5折流板 30

4.6拉杆与定距管 30

4.7壳体与管板、管板与法兰及换热管的连接 30

第五章 结果与展望 32

5.1 设计结果 32

5.2 未来展望 32

参考文献 33

致谢 35

第一章 绪论

1.1研究背景

换热设备是一种用得很多的热工设备,在工业生产中有着十分重要的地位。比如在热力发电厂中与锅炉相关的各种设备,与汽轮机系统有关的一些设备,还有化工行业中的一些热油冷却器等。因此合理地选择和设计换热器,一方面能够使经济效益最大化,另一方面也是为了设备运行的安全[1]。在各种换热器当中,管壳式换热器应用最为普遍,因为其结构不复杂,制造起来方便,传热效果优良,能够适应多种场合[2]。因此本文就已知工艺条件来设计一台管壳式换热器。

1.2国内外研究状况

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。