质子交换膜燃料电池材料机械性能研究毕业论文

2020-07-16 20:15:09

摘 要

质子交换膜燃料电池因其功率密度高、启动快、对负载变化响应灵敏、清洁无污染等优点在能源、汽车、航空等各个领域得到了广泛的应用。弹性体垫片在PEM燃料电池中起到密封作用,长期运行容易导致机械性能下降。因此,研究垫片材料的机械稳定性是必不可少的。本文以PEM燃料电池常用的垫片材料——硅橡胶为研究对象,采用试验方法研究补强填料对PEM燃料电池垫片材料机械性能的影响。本文的主要工作和结论如下;

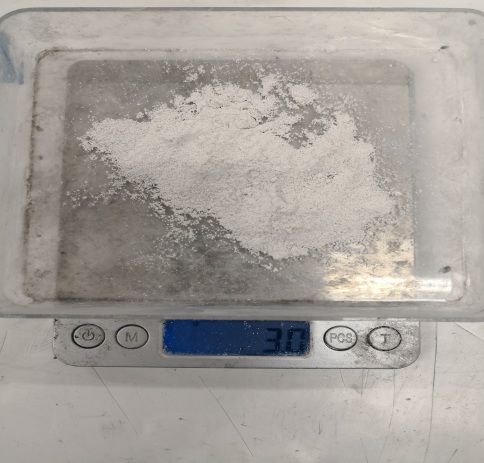

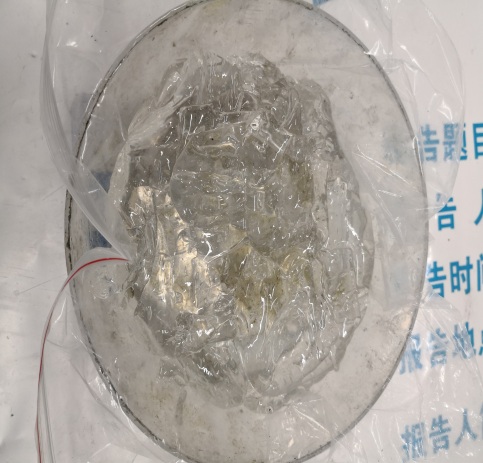

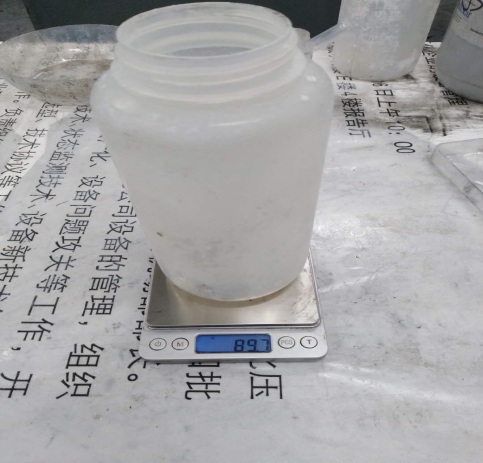

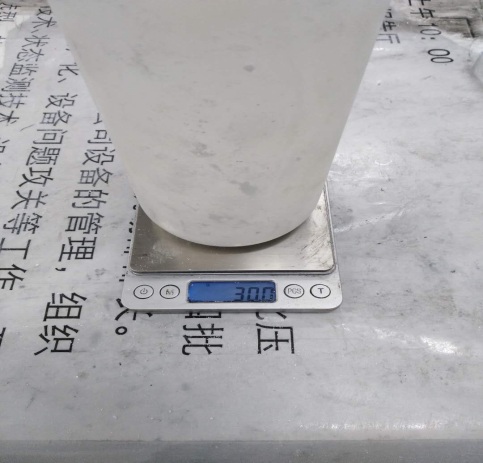

(1)基于PEM燃料电池工作原理,以燃料电池垫片常用的硅橡胶材料作为研究对象,选用白炭黑、碳酸钙作为复合补强填料,设计了一种基础配方,根据硫化特性参数制备了硅橡胶弹性体材料。对基础配方的硅橡胶进行机械性能测试,包括拉伸测定、压缩应力应变测定、压缩应力松弛测定以及压缩永久变形测定。

(2)研究了补强填料比例对硅橡胶材料硫化特性的影响,材料硫化特性参数表明:试样进入热硫化期,各试样的硫化曲线上升速率差异很大,表明补强比对垫片材料硫化速度具有很大的影响作用;当补强比为35/5时,其正硫化时间相对于其他两个配方更短,说明碳酸钙的减少有助于提高橡胶的硫化速率节省硫化时间。

(3)研究了补强填料比例对硅橡胶材料拉伸性能的影响,材料拉伸性能实验结果表明:随着碳酸钙份数的减少,材料的拉伸强度逐渐增大;延伸率、定伸强度和拉伸强度有着同样的趋势;当白炭黑/碳酸钙补强比为35/5时,材料的拉伸性能最好,抵抗外部变形的能力最强。

(4)研究了补强填料比例对硅橡胶材料压缩性能的影响,材料压缩试验结果表明:橡胶损失的能量随碳酸钙份数的增加而减少,当白炭黑/碳酸钙补强比为20/20时,硅橡胶损失的能量最少;在常温下,试样的压缩永久变形随着碳酸钙质量份的增加而减少,弹性损失小,当补强比为20/20时,硅橡胶的压缩永久变形率最小,即表现出最好的压缩回弹性能。

关键词:密封垫片 补强比 机械性能

Study on Mechanical Properties of Proton Exchange Membrane Fuel Cell Materials

ABSTRACT

ABSTRACT

Proton exchange membrane fuel cells(PEMFC) have been widely used in various fields such as energy, automobiles and aviation due to their high power density, quick start-up, responsiveness to load changes and clean, non-polluting properties. As a key component of the PEM fuel cell, the elastomer gasket easily leads to a decrease in its overall performance during its long-term operation. Therefore, the mechanical stability of the gasket material is crucial to the smooth operation of the PEM fuel cell. In this paper, silicone rubber, which is a commonly used gasket material for PEM fuel cells, is studied. The effect of reinforcing fillers on the mechanical properties of PEM fuel cell gasket materials is studied using test methods. The main work and conclusions of this paper are as follows:

(1)Based on the working principle of the PEM fuel cell, taking the silicone rubber material commonly used for fuel cell gaskets as the research object, white carbon black and calcium carbonate are selected as the composite reinforcing filler to design a basic formula. Silicone elastomer materials were prepared The basic formula of silicone rubber was tested for mechanical properties, including tensile testing, compressive stress-strain testing, compressive stress relaxation testing, and compression set testing.

(2)The influence of the proportion of reinforcing fillers on the vulcanization characteristics of silicone rubber materials was studied. The parameters of the vulcanization characteristics of the materials indicated that the samples entered the hot vulcanization phase, and the rate of increase of the vulcanization curve of each sample varied greatly,showing that the reinforcement ratio has a great influence on the vulcanization speed of the gasket material;When the reinforcing ratio is 35/5, the vulcanization time is shorter than that of the other two formulas, indicating that the reduction of calcium carbonate helps to increase the vulcanization rate of the rubber and save the vulcanization time.

(3)The effect of the ratio of reinforcing fillers on the tensile properties of silicone rubber materials was studied. The experimental results of tensile properties of the materials showed that the tensile strength of the materials gradually increased with the decrease of the fraction of calcium carbonate.Elongation and tensile strength have the same trend;When the silica/calcium carbonate reinforcement ratio is 35/5, the material has the best tensile properties and is most resistant to external deformation.

(4)The effect of the ratio of reinforcing fillers on the compression properties of silicone rubber materials was studied. The results of the material compression test showed that the energy lost from rubber decreases with the increase in the number of calcium carbonate parts.When the silica/calcium carbonate reinforcement ratio is 20/20, the silicone rubber loses the least energy; at room temperature, the compression set of the sample decreases with the increase of the calcium carbonate mass, and the elastic loss is small.When the reinforcing ratio is 20/20, the compression set of the silicone rubber is minimized, that is, it exhibits the best compression resilience.

Keywords: sealing gasket; reinforcement ratio; mechanical properties

目 录

摘 要 I

ABSTRACT II

第一章 绪论 1

1.1课题研究背景及其意义 1

1.2 PEM燃料电池简介 1

1.2.1 PEM燃料电池结构 1

1.2.2 PEM燃料电池工作原理 2

1.2.3 PEM燃料电池垫片及补强填料 3

1.3 国内外的研究现状 4

1.3.1 PEM燃料电池垫片材料的研究 4

1.3.2 PEM燃料电池垫片材料机械性能研究 4

1.4本文主要内容 5

第二章PEM燃料电池垫片橡胶材料配方设计及制备 7

2.1 PEM燃料电池垫片橡胶材料配方设计 7

2.1.1 实验材料 7

2.1.2 实验仪器 7

2.1.3 PEM燃料电池垫片橡胶材料的配方设计 8

2.2 PEM燃料电池垫片材料的制备 8

2.2.1 实验准备 8

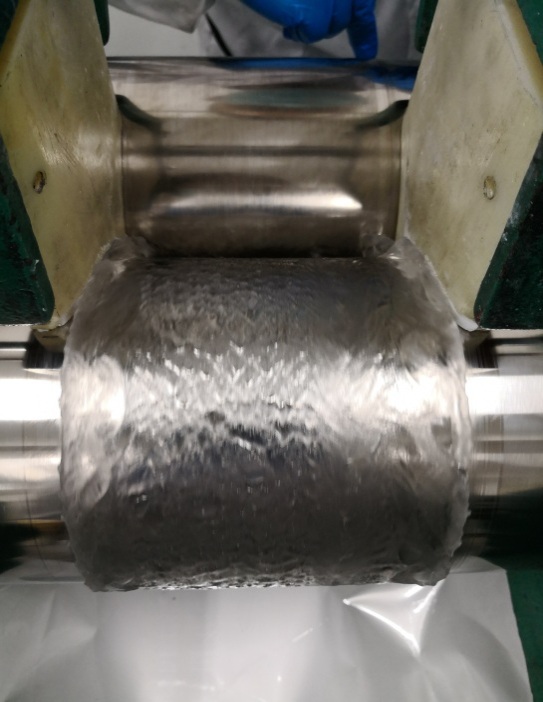

2.2.2 塑炼 9

2.2.3 混炼 10

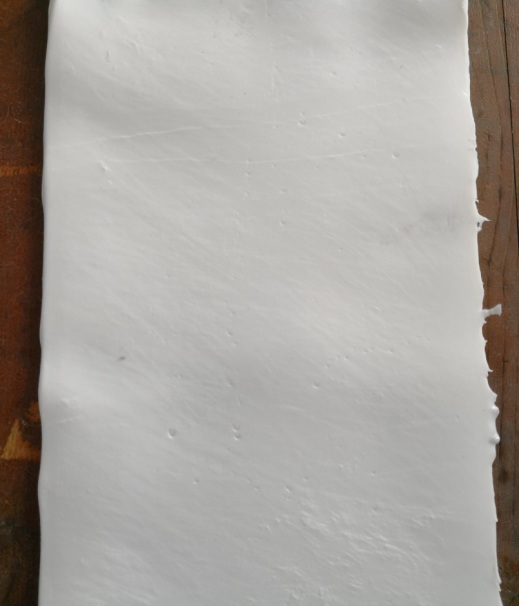

2.2.4 硫化 11

2.3 本章小结 12

第三章PEM燃料电池垫片材料性能研究 13

3.1 机械性能测试 13

3.1.1拉伸性能的测定 13

3.1.2压缩应力应变的测定 15

3.1.3压缩应力松弛的测定 16

3.1.4压缩永久变形的测定 16

3.2 结果分析 18

3.2.1硫化特性分析 18

3.2.2机械性能分析 19

3.3 本章小结 22

第四章 补强填料对PEM燃料电池垫片材料性能的影响 23

4.1 补强比的选取及橡胶材料的制备 23

4.1.1 橡胶配方设计及补强比的选取 23

4.1.2 橡胶材料的制备 23

4.2 材料性能测试及结果分析 24

4.2.1 硫化特性分析 24

4.2.2 拉伸性能分析 25

4.2.3 压缩应力应变分析 27

4.2.4 压缩应力松弛分析 28

4.2.5 压缩永久变形分析 29

4.3 本章小结 30

第五章 结论与展望 32

5.1 主要工作总结 32

5.2 展望 33

5.3 经济性分析 33

5.3.1 投资估算 33

5.3.2 经济效益 33

参考文献 35

致谢 38

第一章 绪论

1.1课题研究背景及其意义

在科学日益发展的今天,人们急需要发展高效率清洁能源。燃料电池是一种能源生产设备,它可以将燃料和氧气的化学能转化为电能,而不会在等温条件下发生直接的电化学反应。只要燃料和氧气剂的供应充足,燃料电池可以连续发电,其高效、无污染、无噪音、可靠等显著优点使其成为了继热能、水力发电,太阳能和核能发电的新一代发电技术。

在各种类型的燃料电池中,质子交换膜燃料电池(Proton Exchange Membrane Fuel Cell, PEMFC)因其操作温度(约80℃)低、启动快、功率密度高、对负载变化响应快等优点[1,2]正逐步走近我们的生活。凭借这些优点,PEM燃料电池在应用方面也取得了很好的发展,从固定式的电池堆发展成为便携式、移动式和微型燃料电池,在汽车、混合动力等行业得到了较为广泛的应用[3-6]。由于PEM燃料电池的优秀特性,不少潜艇也采用其来克服传统柴油带来的动力缺陷[7]。此外,该电池主要用于电网调峰电力系统、大容量混合储能推进系统、远程电网储能系统、独立建筑储能、高空长航太阳能飞行器等等[8]。PEM燃料电池的高性能将会带来不可估量的经济和环境效益。

燃料电池阳极和阴极的反应气体主要由弹性体垫片来密封,垫片的机械稳定性下降或材料失效,都会引发PEM燃料电池的安全性问题。因此,研究垫片材料的机械性能对PEM燃料电池的稳定性至关重要。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。