轻型轿车制动系统的设计毕业论文

2020-04-08 13:28:27

Graduation Design (Dissertation) of Wuhan University of Technology

Design of Brake System of Light Sedan Based on Hyundai Electra

College: International Education College

Specialty amp; Class: Automobile GJ1401

Student name: Ziyan Dong

Tutor: FangFang Duan

Statement of Originality

I solemnly declare that the thesis I submit is a piece of writing I completed independently based on my own research under the guidance of my supervisor. Except for the quotations, this paper does not include any writings published or completed by other individuals or groups. I am fully aware that the legal consequences of this statement are borne by me.

Signature of the author:

Date:

Copyright Letter of Authorization to The Dissertation

The author of this dissertation fully understands provisions stipulated by this school on keeping and using dissertations. The author agrees that the school can reserve and send photocopies and electronic versions of this thesis to relevant departments or institutions managing dissertations. This thesis can be read and borrowed. I hereby authorize excellent provincial institutions appraising bachelor dissertations to incorporate all or any part of this dissertation into relevant databases for retrieval, as well as to preserve and compile this dissertation by photocopying, scanning or reprinting it in a reduced format.

This dissertation is: 1. Confidential until(year) and then this authorization letter will apply. 囗

2. Non-confidential. 囗

(Please tick "√" the corresponding box above)

Signature of the author:

Date:

Signature of the tutor:

Date:

ABSTRACT

Brake is one of the most important components to ensure the safe driving of a car. Therefore, the performance of the brake system directly affects the safety of drivers and passengers. With the rapid development of Chinese economy and the gradual maturity of the automobile manufacturing industry and related markets, more and more motor vehicles have entered millions of households. In the past two decades, the number of motor vehicles in China has grown spurt, and the number of drivers has also increased dramatically. As a result, the roads in major cities have gradually become crowded and the road conditions have become more complex. Moreover, the current entry threshold of the driver is gradually reduced, so the performance of the brake system is more important than the old-fashioned cars. In order to allow more people to easily control the car, the response speed of brake system becomes very important. If the old drum brake system structure is still used, although the manufacturing cost of the automobile can be controlled at a relatively low level, its closed structure determines that it is more prone to failure due to overheating and brings security risks to the vehicle and its members. Also, because its braking response is relatively slow, resulting in poor control accuracy, which is difficult to improve the smoothness of the vehicle. With most women becoming the new generation of drivers, the brake booster system has become crucial. Therefore, for current vehicles, brake performance, brake response speed, brake pedal force and performance degradation after long-term braking are generally taken as the main design parameters when designing the brake. This article selects the parameters of the light car that are currently sold in the market as the design reference, designs and determines the parameters of the brake, and uses the three-dimensional modeling software to model the completed brake and convert it into a two-dimensional design drawing. Finally, the strength of the brake disc is analyzed and calculated using finite element analysis software.

Keywords:Disc brake system, three-dimensional modeling, parameter design

CONTENTS

CHAPTER 1 INTRODUCTION 6

1.1 RESEARCH SIGNIFICANCE 6

1.2 RECENT RESEARCH STATUS 6

1.3 CHAPTER SUMMARY 8

CHAPTER 2 OVERVIEW OF THE BRAKE SYSTEM 9

2.1 FUNCTION OF THE BRAKE SYSTEM 9

2.2 STRUCTURES OF THE BRAKE SYSTEM 9

2.3 TYPES OF THE BRAKE SYSTEM 9

2.4 PRINCIPLE OF THE BRAKE SYSTEM 10

2.5 CHARACTERISTIC OF DRUM BRAKES 11

2.6 CHARACTERISTIC OF DRUM BRAKES 12

2.7 CHAPTER SUMMARY 13

CHAPTER 3 PARAMETER DESIGN OF THE BRAKE SYSTEM 14

3.1 MAJOR PARAMETERS OF BRAKE SYSTEM 14

3.1.1 Braking force distribution coefficient and synchronous adhesion coefficient 14

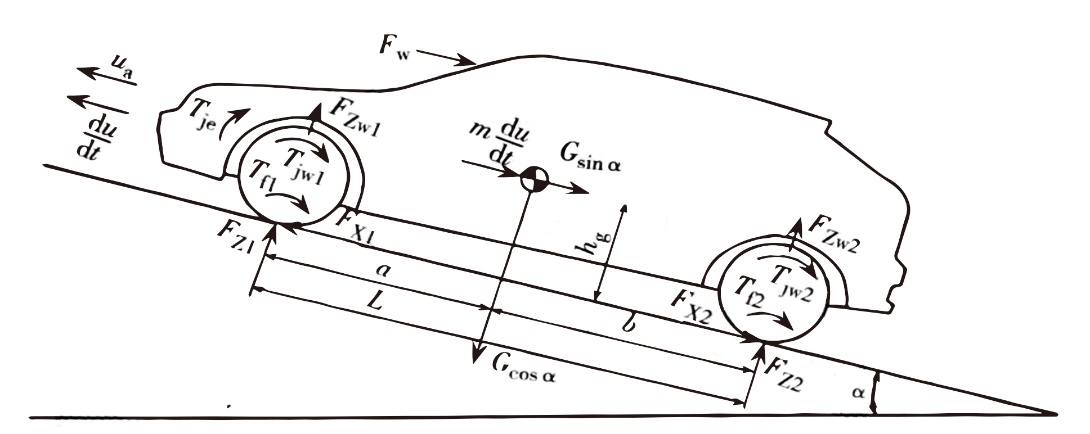

3.1.2 Calculation of vehicle front and rear wheel attachment torque 15

3.2 DESIGN AND CALCULATION OF BRAKE SYSTEM 16

3.2.1 Brake factor of disc brake system 16

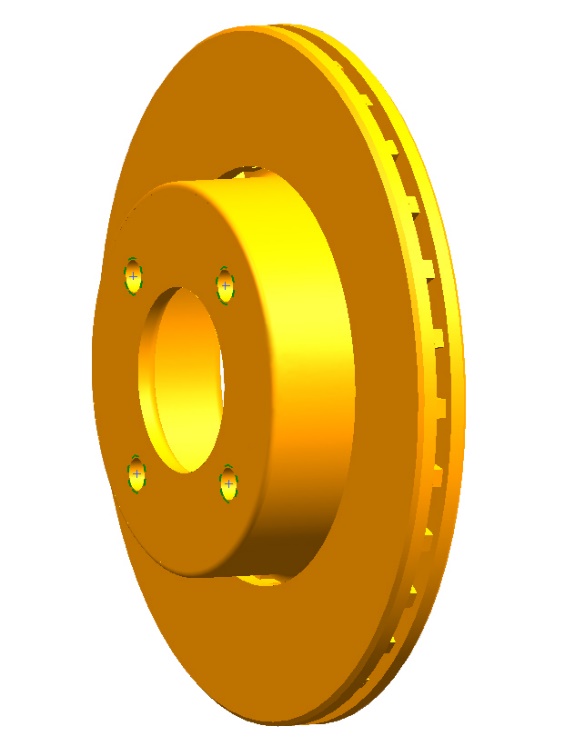

3.2.2 Diameter of the brake disc 16

3.2.3 Thickness of the brake disc 17

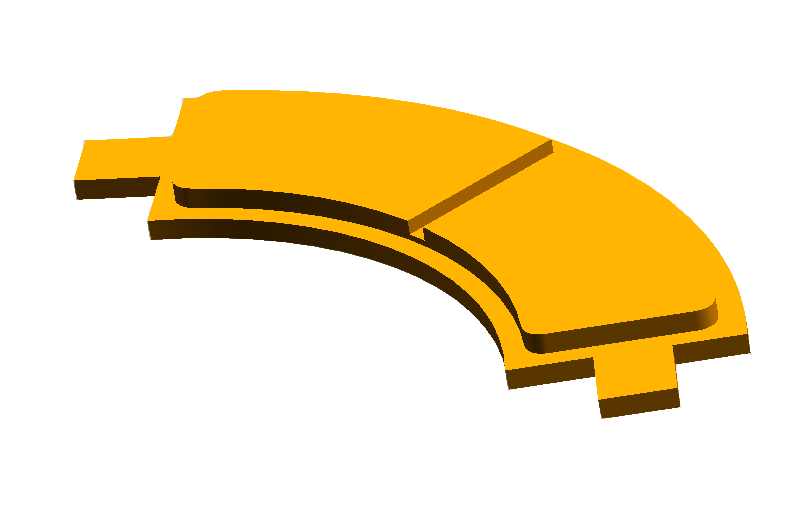

3.2.4 Parameter of the brake pads 17

3.2.5 Working area of the brake pads 17

3.2.6 Braking torque of the brake system 18

3.2.7 Braking torque and the maximum pressing force 18

3.2.8 Energy dissipation ratio 19

3.2.9 Specific friction force 20

3.2.10 Braking torque required for emergency braking 21

3.2.11 Parking brake required braking torque 21

3.3 DESIGN AND CALCULATION OF DRIVE MECHANISM OF BRAKE SYSTEM 22

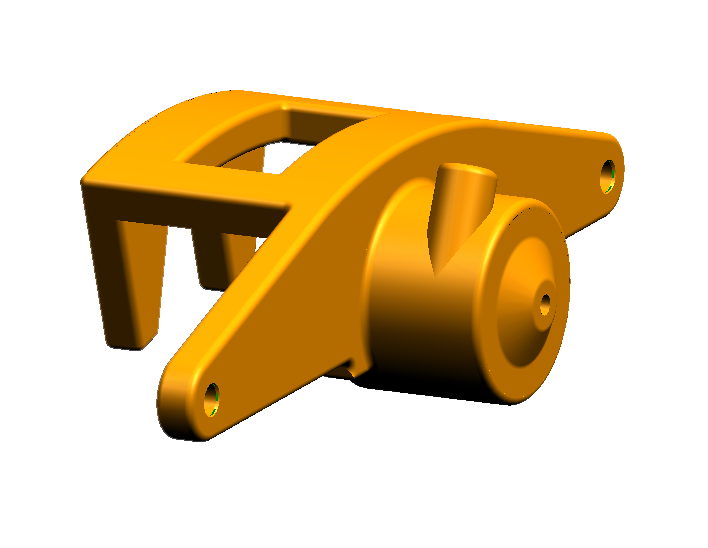

3.3.1 Pressure of the wheel brake cylinder 22

3.3.2 Diameter of the wheel brake cylinder 22

3.3.3 Working volume of single wheel brake cylinder 23

3.3.4 Working volume of major brake cylinder 23

3.3.5 Diameter of major brake system 24

3.3.6 Pedal force of brake system 24

3.3.7 Stroke of brake pedal 25

3.4 CHAPTER SUMMARY 25

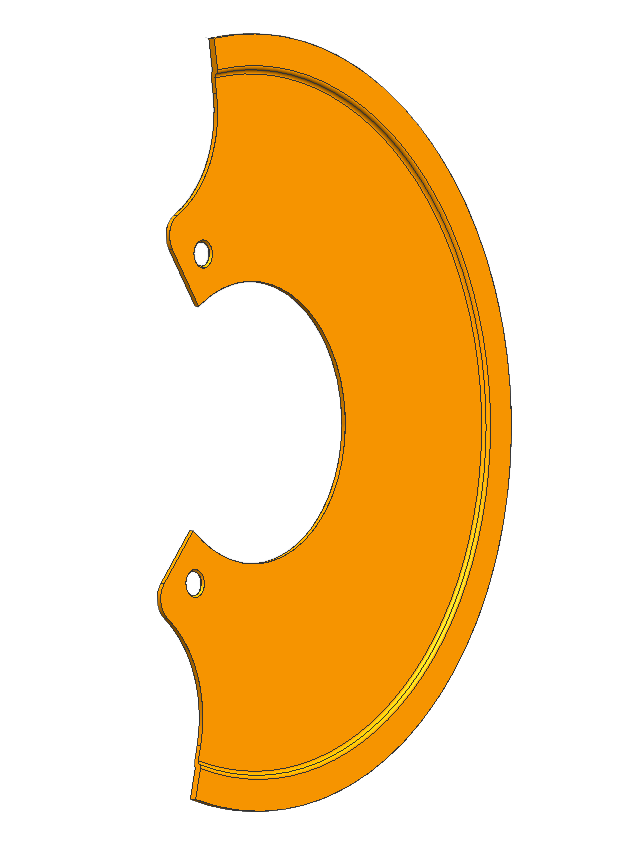

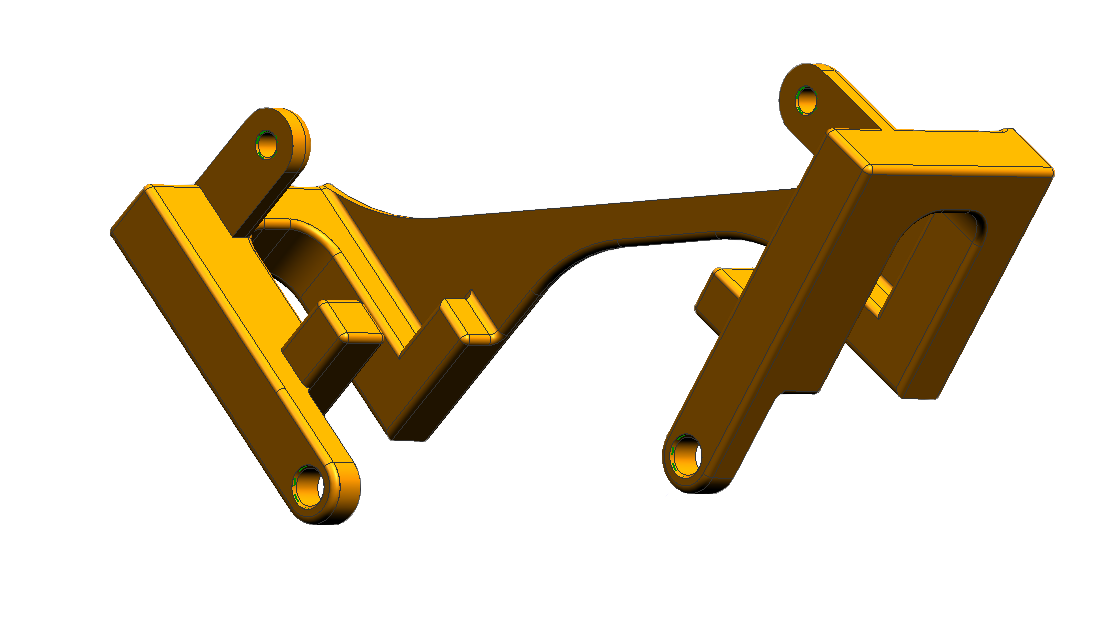

CHAPTER 4 MODELING OF BRAKE SYSTEM 26

4.1 MODELING SOFTWARE 26

4.1.1 Modeling of major part of brake system 26

4.1.2 Modeling of secondary part of brake system 27

4.1.3 Modeling of standard part of brake system 30

4.1.4 Assembly of brake system part 30

4.2 DRAWING OF THE ENGINEERING BLUEPRINT 31

4.3 ANALYSIS OF MODEL OF BRAKE SYSTEM 31

4.4 CHAPTER SUMMARY 33

CHAPTER 5 OUTLOOK AND CONCLUSION 34

5.1 IMPORTANCE OF THE BRAKE SYSTEM 34

5.2 EVOLUTION OF BRAKE SYSTEM FORM 34

5.2.1 Drum brake system 34

5.2.2 Disk brake system 35

5.2.3 Regenerated brake system 35

5.3 OPTIMIZATION DESIGN OF BRAKE SYSTEM STRUCTURE 36

5.3.1 Optimization design of drum brake system structure 37

5.3.2 Optimization design of disc brake system structure 38

5.4 CONCLUSION 39

REFERENCE 40

CHAPTER 1 INTRODUCTION

1.1 RESEARCH SIGNIFICANCE

With the rapid development of Chinese auto industry, relying solely on joint ventures to produce foreign brands of vehicles is no longer in line with the pursuit of domestic auto companies. The launch of excellent self-developed products is the goal pursued by every vehicle manufacturer. Therefore, the design and optimization of the vehicle system are also on the agenda. As the system that most affects the safety performance of automobiles, the brake system has always been valued by researchers at domestic and abroad product. A good braking system is a guarantee of vehicle safety, and an outstanding braking system should also have better reliability. Thus, the design and manufacture of braking systems with better performance have also become crucial.

1.2 RECENT RESEARCH STATUS

With the development of the level of science and technology and the advancement of economic level, the quantities of cars have also increased year by year. So, the requirements for the stability and braking of automobiles are also increasing. As the car gradually enters millions of households, the capability of the driver gradually become mixed. Therefore, the traditional hydraulic braking system obviously cannot meet the increasingly severe requirements. And with the year-by-year improvements in automobile manufacturing technology and machining accuracy, electronic control mechanisms and traditional hydraulic structures can effectively cooperate, which made the anti-lock braking system (ABS) has become popular in automobiles. The distribution strategy of brake force and related laws and regulations have also been improved[1,2]. For some older passenger cars and cheaper entry-level passenger cars, they still use outdated drum brakes on the rear axle. Compared to disc brakes, drum brakes have less braking stability and poor resistance to thermal degradation and high temperature. Moreover, the application of drum brake system on heavy duty trucks may easier to cause the traffic accident[3,4]. Therefore, new types of passenger cars and most commercial vehicles mainly use disc brakes as a braking system.

In the analysis and calculation of the vehicle brake system performance, the traditional method only considers the car's ultimate braking performance on a good road. But for a car that is actually on the road, describe the performance of vehicle brake system with the constant adhesion coefficient may mask many important braking phenomena. Therefore, in the analysis of the vehicle braking performance, the parameters of the slip ratio of the tire in the braking process are added, and the factors that can influence the braking process such as the variation of the wheel radius during braking are taken into account[5].

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。