载货汽车的驱动桥设计毕业论文

2020-04-08 13:29:17

Graduation design of Wuhan University of Technology

Design of driving axle of freight car

College (Department):Institute of International Education

Class:Gj1304 class of vehicle engineering

Name:Yunfei Zhang

Instructor:Fangfang Duan

Wuhan University of Technology

2018.5

Catalog

abstract 4

Chapter 1 Introduction 5

1.1.The purpose and significance of the topic selection. 5

1.1.1.The significance of topic selection 5

1.1.2.The purpose of topic selection 5

1.1.3.Analysis of current research status at homeland and abroad 5

1.2.Basic content and technical scheme 6

1.2.1.The basic content of this design 6

1.2.2.design scheme 7

Chapter 2 Determination of the overall scheme of the driving axle 8

2.1.Definition, classification, structural form, design requirements and design parameters of vehicle driving axle 8

2.1.1.The definition of vehicle axle 8

2.1.2.Type of vehicle axle 8

2.1.3.Classification of driving axles 9

2.1.4.The structure of the driving axle 9

2.1.5.The requirements of this design 10

2.1.6.Model parameters of this design 10

2.2.Determination of the structure scheme of the main reducer 11

2.2.1.Determination of the ratio of main deceleration 11

2.2.2.The determination of the type of the gear of the main reducer 11

2.2.3 Determination of the deceleration form of the main decelerator 13

2.2.4 Supporting form and installation method of driven bevel gear of main reducer 13

2.3.Structural scheme determination of differential 16

2.4.Determination of the form of a half axis 16

2.5.Determination of the form of the axle shell 17

Chapter 3 Design of main decelerator 19

3.1 Summary 19

3.2 The selection and strength calculation of the gear parameters of the main reducer 19

3.2.1 Determination of the calculation load of the gear of the main reducer 19

3.2.2.The selection of the gear parameters of the main reducer 22

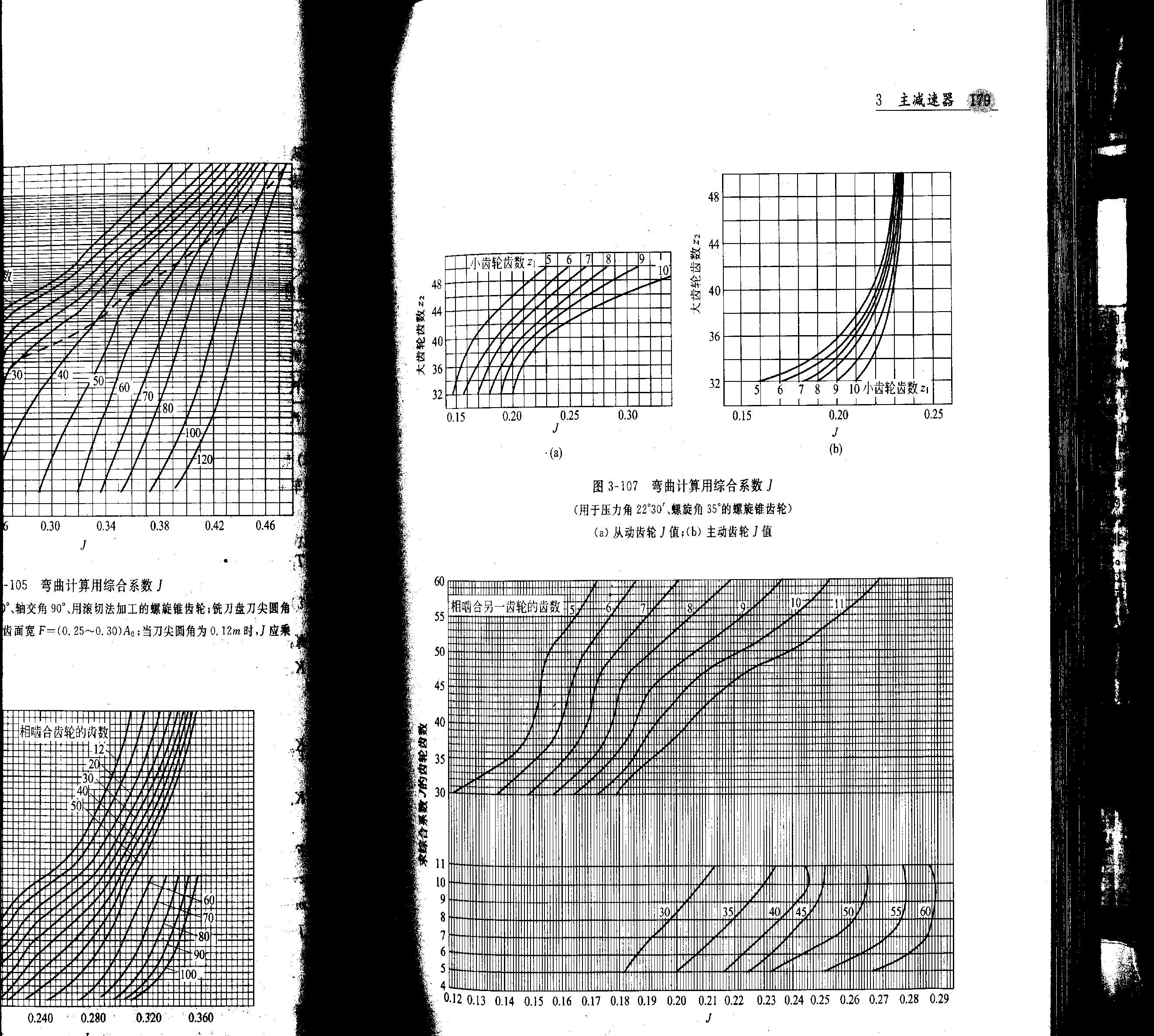

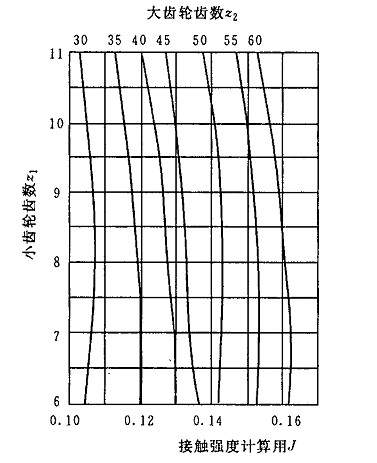

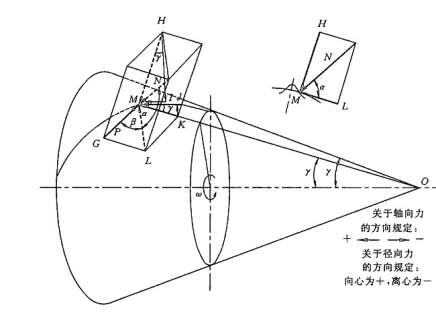

3.2.3.Strength calculation of spiral bevel gear 27

3.2.4.Bearing calculation of the main decelerator 36

3.3.main reducer gear material and heat treatment 45

3.4.Lubrication of the main decelerator 46

3.5.Summary 47

Chapter 4 Differential design 48

4.1.Summary 48

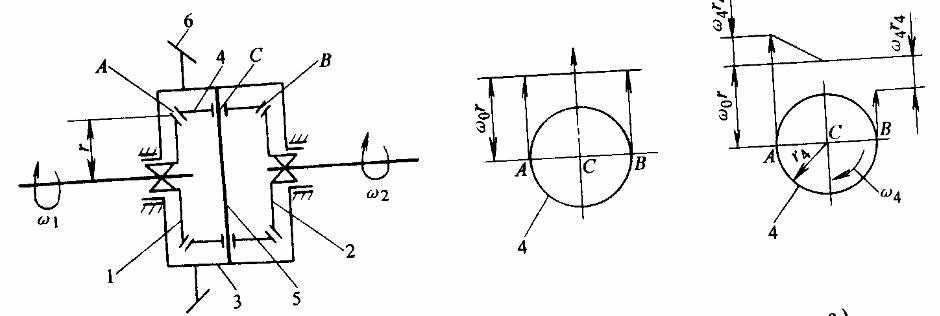

4.2.The principle of symmetrical conical planetary gear differential 48

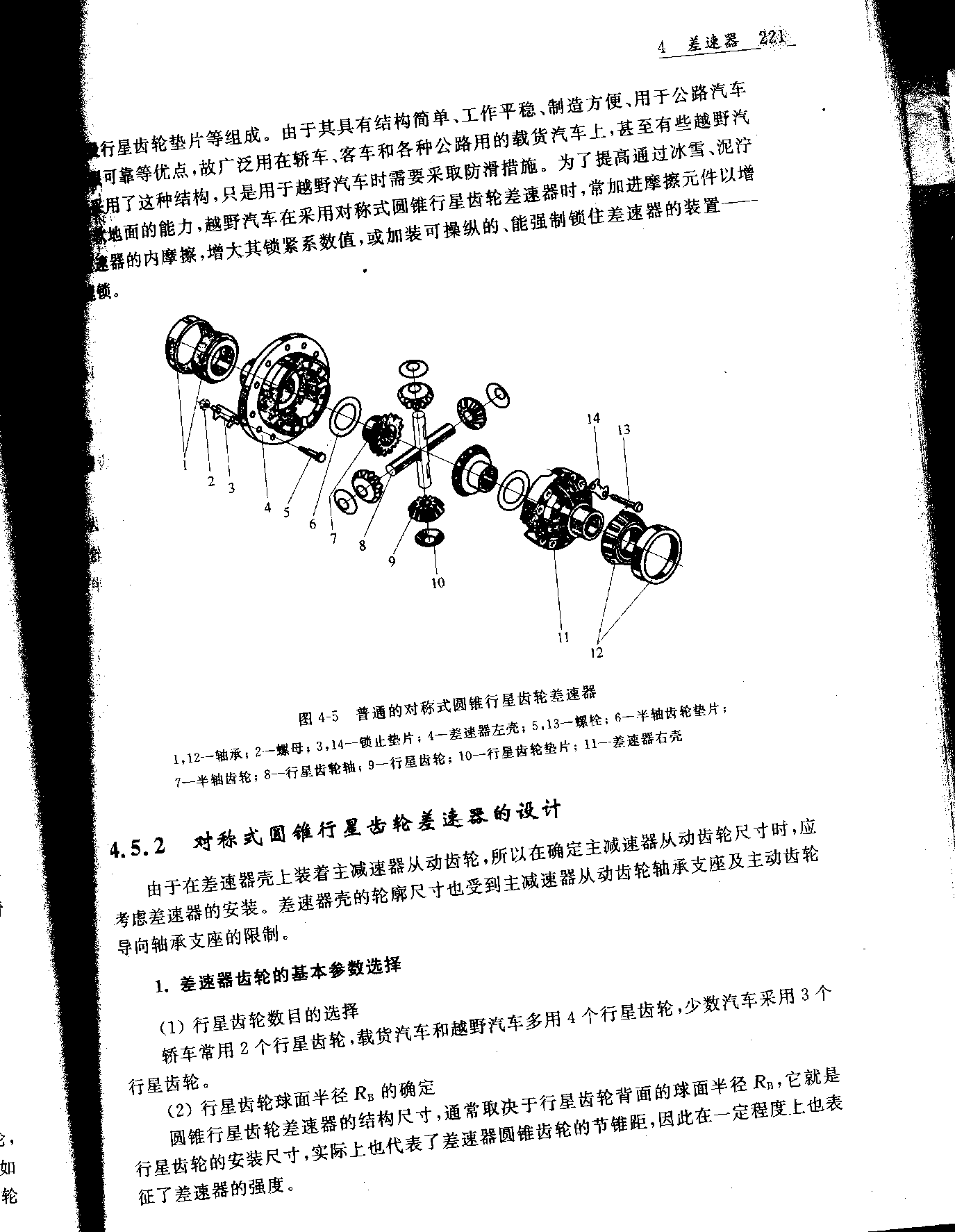

4.3.The structure of the symmetric conical planetary gear differential 50

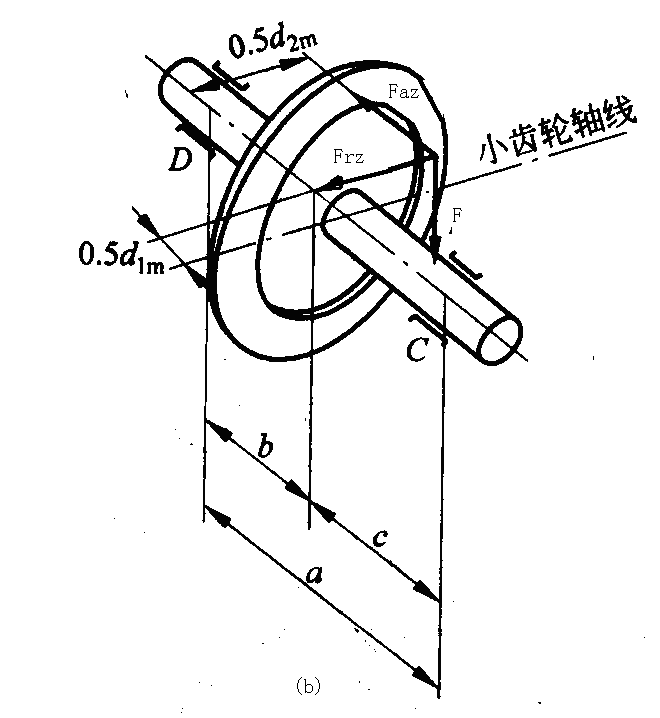

4.4.Design of symmetric conical planetary gear differential 51

4.4.1.Selection of basic parameters of differential gear 51

4.4.2.Geometric size calculation of differential gear 54

4.4.3.Geometric size calculation table for straight bevel gears of automobile differential 55

4.5.Strength calculation of differential gear 58

4.6.Material of differential gear 60

4.7.Summary 60

Chapter 5 Design of semi axle and driving axle shell 61

5.1.Summary 61

5.2.Design and calculation of half shaft 62

5.2.1.Determination of the calculated load of a fully floating semi shaft 62

5.2.2.The primary selection of the diameter of the full floating half shaft 64

5.2.3.Strength calculation of full floating semi shaft 64

5.2.4.Calculation of the strength of full floating semi axle spline 64

5.2.5.Semi axle material and heat treatment 66

5.3.Stress analysis and strength calculation of the axle shell 67

5.3.1.Calculation of static bending stress of a axle shell 67

5.3.2.Strength calculation of axle housing under impact load of uneven road surface 70

5.3.3.Strength calculation of axle housing when driving vehicle with maximum traction force 70

5.3.4.Strength calculation of axle housing in emergency braking of automobile 73

5.4.Summary 74

Conclusion 75

Reference 76

abstract

As a country which attaches great importance to the development of industry and agriculture, our country attaches great importance to the development of transportation industry, so the freight car occupies a large proportion in the production of commercial vehicles. Because of the special working conditions of trucks, the design of driving axle is particularly important in the development and manufacture of freight cars. As one of the main components of a car, the driving axle needs to withstand the reaction force to the car. Therefore, in order to meet the people's requirements on the efficiency, safety and speed of the freight car, it is necessary to ensure that the driving axle can be used safely, cheap, practical, efficient and convenient, and the performance is reliable.

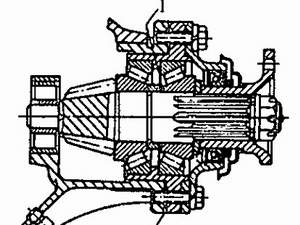

In this design, I understand and discuss the overall structure of the driving axle by consulting the documents and magazines. After seeing a large number of driving axle design examples, domestic and foreign research status and the users' feedback, the overall design scheme is determined. 1 the single machine reducer is used as the main driver for the overall driving axle design 2. The deceleration form of the reducer, the main reducer gear adopts spiral bevel gear 3 and the conical planetary gear differential 4 uses the full floating half shaft 5 to choose the cast integral axle shell. In this design, we mainly completed the design and verification of the main components of the driving axle, including the reducer, differential, full floating axle shaft and driving axle housing. Finally, use CATIA, AutoCAD and other software to complete the drawing of main parts and assembly drawings.

Key words: truck; driving axle; main reducer; differential; half axle; axle housing

Chapter 1 Introduction

1.1.The purpose and significance of the topic selection.

1.1.1.The significance of topic selection

In today's society, the industrial capacity of a country is the basis of a nation's comprehensive national strength, and transportation, like blood, is generally circulating in the industrial system, with a large and small industrial zone in series. In the industrial transportation, the highway transportation accounts for a great proportion, especially in some short haul transportation, so the performance of the vehicle (freight car) is closely related to the transport efficiency.

With the development of China's automobile manufacturing industry and the improvement of automobile design level, the cars produced become more efficient, stable, safe and environmental protection. As a result, most of our country's current loading and riding vehicles are mainly after the post drive. The main reason for this design is to increase the load of the car, improve the power of the car and simplify the arrangement of the manipulating mechanism.

The power transmission route of the front rear drive vehicle is the engine one transmission, one transmission shaft, one main reducer, one differential drive half axle and one wheel. The main decelerator, differential, half shaft and driving axle housing constitute the driving axle assembly of the car, which is the last part of the automobile transmission system, whose function is to distribute the power from the drive shaft to the driving wheel and increase the torque. Therefore, the design of driving axle is an important part of vehicle design.

1.1.2.The purpose of topic selection

1) by learning and designing the vehicle driving axle, we can further enhance our understanding of the automobile, which is an important practical opportunity.

2) through this design, we can exercise the ability of consulting and processing data literature, which is of great significance in the future work and study.

3) the information in the design can enhance the understanding of the development of modern automobiles.

4) through the driving axle design, we can train and enhance the use of automotive design software, including autoCAD, CATIA, ANSYS and so on.

1.1.3.Analysis of current research status at homeland and abroad

With the improvement of vehicle design level and the development of automobile manufacturing industry, the design and manufacturing process of driving axle are becoming more and more perfect. In order to meet the requirements of our country's socialist market economy and the trend of automobile development at home and abroad in the future, the adjustment and upgrading of automobile design should be promoted so as to meet the increasing demand of China's industry to the automobile. The design of automobile driving axle is developing towards the direction of "standardization of parts, generalization of parts and serialization of products".

With the development of automobile design and highway network, people have put forward higher requirements on the environmental protection of vehicles while emphasizing efficiency. Therefore, the development of truck engines should develop towards the direction of large torque and low speed. In order to adapt to the above changes, the speed ratio of automobile driving axle should be reduced, so the bipolar deceleration design used in the past should be eliminated and replaced as a monopole reducer to achieve the advantages of simple structure, higher transmission efficiency, less vulnerable parts and higher reliability. From the design point of view, when the main vehicle reduction ratio is less than 7.6, the unipolar deceleration driving axle should be selected as far as possible. At present, unipolar deceleration driving axle has been widely used in foreign freight cars, and has been widely recognized by users. Some of the most technologically advanced companies have taken the monopole deceleration axle as its main product, including the United States Eaton Corp (EATON), the Rockwell Automation (Rockwell Automation), the German ZF (ZF), and the man group (MAN).

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。