轻型侧位道路清障车的总体布置与设计毕业论文

2020-04-10 16:41:04

摘 要

本文运用三维建模软件SolidWorks,首先针对轻型侧位道路清障车进行了方案探讨,进而进行整车建模;同时查阅了相关资料,对此类型清障车的总体布置进行设计,所得结果对于清障车未来的发展方向具有重要的指导意义。

论文主要对这种新型车辆进行了结构方案的设计和总体布置的规划。

研究结果表明:清障车从侧面进行清障具有理论的可行性,基于它相比一般的道路清障车而言更加方便,对场地要求也减小,所以设计这样一种清障车具有重要的研究意义。

本文的特色:本文设计的清障执行机构具有一定的创新性,总体布置与设计也具有良好的可操作性。

关键词:侧位清障车;结构方案;底盘选型;

Abstract

This article takes advantage of the 3D modeling software SolidWorks. First of all, the article discusses the scheme of the light side road wrecker, and then carries on the vehicle modelling, and consults the related materials to design the overall layout of this type of wrecker. The results obtained have important guiding significance for the future development direction of the wrecker.

The dissertation mainly focuses on the design of the structural scheme and the overall layout of the new vehicle.

The results of the study show that the wrecker has theoretical feasibility for removing obstacles from the side. Because it is more convenient than the ordinary road wrecker, and the site requirements are also reduced, so designing it has important research significance.

The characteristics of this article: The design of the obstacle clearing implement has a certain degree of innovation, and the overall layout and design are maneuverable.

Key Words:Side Wrecker; structure design; chassis selection

Table of Contents

Chapter 1 Introduction 1

1.1 Research Background 1

1.2 The aim and meaning of the research 4

Chapter 2 Introduction 5

2.1 Argumentation of the Structural Plan 5

2.1.1 Chassis load quality utilization factor 5

2.1.2 The weight of the special equipment 5

2.2 Select structural scheme 6

2.2.1 Horizontal slide structure scheme 6

2.2.2 Vertical lifting mechanism structure scheme 7

2.2.3 Support arm structure scheme 7

2.2.4 Overall structure plan 8

2.3 Determination of hydraulic control 9

Chapter 3 Wrecker Chassis Selection and Design 11

3.1 The determination of the quality parameters of the wrecker 11

3.1.1 Maintenance quality 11

3.1.2 Total mass 11

3.2 The selection of wrecker engine parameter 11

3.2.1 Maximum engine power and its corresponding speed 11

3.2.2 Maximum engine torque and its corresponding speed 12

3.2.3 Engine adaptability coefficientφ 12

3.3 Related parameters of the chassis 13

3.4 Related calculations of the chassis 14

3.4.1 Conditioning mass and axle load distribution 14

3.4.2 Performance parameters 14

3.4.3 Size parameters 15

Chapter 4 The design of Power take-off 17

4.1 The principle and requirement of power take-off 17

4.2 The selection of power take-off 18

Chapter 5 The design of hydraulic system 22

5.1 The introduction and principle of hydraulic system 22

5.2 Hydraulic cylinder structure design 24

5.3 Hydraulic pump device 25

5.3.1 Hydraulic pump installation 25

5.3.2 The connection of hydraulic pump and motor 26

Chapter 6 Design and calculation of actuator 28

Chapter 7 Conclusion 31

References 32

Express thanks 33

Chapter 1 Introduction

1.1 Research Background

Road wreckers are also called trailers or accident rescue vehicles. It consists of a chassis, lifting device, lifting traction device, hydraulic system, electronic control system, body and toolbox. It is equipped with lifting, towing, lifting and other devices on the basis of a dedicated cargo chassis. It has a number of functions such as lifting, dragging, pulling and lifting, and is suitable for the clearing of highways and urban roads. It is inevitable that some accidents will occur when the car is on the road, especially on the highway. The task of the wrecker is to reach the scene of the accident with the fastest speed after the accident and to remove the faulty vehicle or the accident vehicle from the scene at the first time. It can ensure that the target road can be unimpeded and facilitate other vehicles. Therefore, road wreckers are also called emergency vehicles. Compared with other special vehicles, the road wrecker has a relatively short history of development. It is mainly used to clear accident vehicles and remove road obstacles. Side road wreckers are characterized by the ability to lift accidents or faulty vehicles from the side.

China's road wreckers started in the early 1990s. At that time, the social demand was small, and the style structure was mostly in the form of hanging. With the speeding up of the expressway industry in China, the demand for wreckers has entered the period of the outbreak after this century, the wrecker technology has been greatly promoted, and product design technology and manufacturing technology have also achieved breakthrough development. In the past 20 years, China's wrecker industry has experienced the process of introducing complete vehicles, absorbing imitations, and independently developing wreckers. The type and level of the product have also been gradually increased and improved from the original hanger type and the flat-bottom tray type.

However, we still have a big gap compared with the advanced developed countries' wrecker technology. For example, the U.S. wreckers started earlier, advanced technology, and the product has three major characteristics. First, the variety is full-featured. From light to super heavy tonnage, there are all kinds of wreckers with different specifications and functions. Second, the structure is novel and beautifully manufactured. The overall appearance is beautiful and full of creativity, and the structure is compact and nuanced. Third, new materials and new technologies are widely used. For example, high-strength plastic materials are used in the body of wreckers, and aluminum-type materials are used for rolling shutter door type toolbox doors and aluminum flat plates. Advanced electronic control technologies and equipment are also commonly used in system monitoring and integration control. This makes the wrecker safer and more reliable to use.

In addition to technology, the gap is also reflected in the company itself, national conditions and other factors, thus constraining the development of the wrecker industry. The main problems existing in China's wrecker industry are: (1) Announcement management system constrains industry development. China's wreckers use a product announcement system. The Ministry of Industry and Information is responsible for product announcements, the Ministry of Environmental Protection is responsible for the environmental protection announcement, the AQSIQ is responsible for the 3C announcement, the public security traffic control is responsible for the vehicle's license, and the Ministry of Transport is responsible for the fuel announcement. The announcement of product announcements has a long process cycle and is not conducive to the research and development of new products. In addition, the production volume of wrecker vehicles is clearly different from that of passenger vehicles and ordinary trucks. The number of passenger cars and trucks is large. A certain model can sell tens of thousands or even hundreds of thousands of vehicles. The production of wreckers is premised on market orders. It is mainly modified on the basis of the second-class chassis of trucks. For many varieties, small volume production, market promotion limited, may only sell a few vehicles a year. (2) Poor adaptability of relevant industry standards. For example, the "Technical Conditions for Motor Vehicle Operation Safety" (GB 7258-2012) regards the on-board quality of dedicated vehicles as a limiting parameter. It is unreasonable to neglect dedicated functions. Since the chassis quality of some models is small, manufacturers must not meet the requirements for carrying quality. Does not reduce or reduce the special functions, learn from the foreign special-purpose vehicles to their total mass restrictions, cancel the requirements of quality requirements. (3) Product intellectual property is not protected. Due to the restrictions of announcement management, in order to bring wreckers to market as quickly as possible and expand the coverage of product use, Chinese manufacturing companies pay attention to the realization and maximization of product functions, often neglecting product details. Processing and optimization design. In addition, the vicious competition between companies, product imitation, blind pursuit of the low price, resulting in domestic wreckers cheap but not beautiful things, product quality is difficult to improve. (4) Production companies blindly pursue large and complete. The gap between domestic and imported wreckers is mainly reflected in the word “professional”. The more specialized vehicle manufacturers, the less products they can produce. The wrecker manufacturers in foreign countries are all focused on researching and producing their own specialty products. The scale is generally not large. They mainly rely on specialization and excellence to achieve market recognition and dominate the market in their respective fields. In particular, the production companies in Europe, the production methods for the former shop after the factory, specialized division of labor, modular assembly, variety changes quickly, quality assurance, high production efficiency. Therefore, wrecker manufacturers should not be large and complete. They should take the path of specialization to do a good job in the market and do a good job of services. (5) Chassis and key components can not keep up. At present, the biggest problem faced by domestic wreckers is the lack of dedicated chassis, such as high-power pickup trucks, heavy-duty chassis over 40 tons and so on. Due to the small quantity and low price of other accessories, supporting companies are reluctant to develop, affecting the development of the types of wreckers and improving the performance and technical level. (6) Lack of unified management practices and standards. China's roadblocked, rescue, rescue, and smooth services were opened to the public as market behaviors, and they gradually became socialized after 2000. Most of the social obstacle-relief and rescue enterprises were established within less than ten years, from the industry's operational norms to the strengths, services, and management of enterprises. Other aspects are in the starting stage. In particular, the barriers to entry of the rescue industry are low, and the quality of service and service vary greatly. This has caused vicious competition in the road clearance and rescue market in China and the decline in corporate integrity, which has seriously affected the survival and development of road obstacle rescue and rescue industries and also affected the country’s wreckers. The overall sustainable development of the industry.

1.2 The aim and meaning of the research

Wreckers are mainly divided into categories according to categories: towing conjoined type, towing separation type, one for one type, flat one for two, multi-purpose wrecker. Wreckers are classified as light, medium-heavy and super-heavy in accordance with their ability to remove obstacles. The light wreckers are aimed at light duty trucks and light cars. The medium and heavy wreckers are targeted at heavy duty trucks and light buses. Super heavy wreckers are targeted at heavy trucks. Heavy-duty passenger cars and super-heavy semi-trailer series. With the acceleration of the development of traffic road construction in China, the market demand for wreckers is also increasing, and the main development trend is gradually extended to humanized design and humanized services. In the future, China's wreckers should be extended to two at the tonnage, such as the small tonnage below 3.5 tons, large tonnage above 50 or 60 tons, the small tonnage is mainly pickup, light and flexible to meet the city's rapid rescue under different circumstances . Large tonnage In addition to vehicles with more than five axes, semi-trailer flat wreckers should be developed to meet the rescue of buses on the highway. Second, multi-purpose wreckers should be developed, such as adding truck cranes, multiple winches, and emergency equipment. Its focus is on the functional layout of the vehicle, appearance design, and automation of operations, providing more convenient and user-friendly operation for the use of customers. Among them, the side road wrecker is a developing vehicle. It is more convenient than ordinary road wreckers, and it also has less site requirements. Therefore, it has important research significance for the overall arrangement and design of roadside wrecker.

Chapter 2 Argumentation of the Structural Plan

2.1 Improve the load quality utilization factor

The automobile quality utilization coefficient describes the relationship between the vehicle rigging quality and loading quality. The quality utilization factor or the utilization quality utilization factor is usually used as an evaluation index to evaluate the pros and cons of the vehicle's quality utilization ability. The increase in the utilization factor of the load quality will help reduce the operating costs of the vehicle.

For lightweight side road wreckers, its load quality utilization factor is mainly composed of two aspects: the utilization coefficient of the load capacity of the chassis and the self-respect of the removal-specific equipment.

2.1.1 Chassis load quality utilization factor

To improve the utilization factor of the load capacity of the chassis, the following points should be taken into consideration when selecting the chassis:

①Powerful;

②Relatively light weight;

③High technical content;

Chassis selection for this design should select the chassis that satisfies the above characteristics.

2.1.2 The weight of the special equipment

Because the structure of the evacuation device (executing mechanism) of the wrecker is relatively complex and the weight is relatively large, new materials and manufacturing processes should be adopted as much as possible when designing the device. In addition to the main components, the rest of the accessories use lighter-weight injection molded parts. In addition, the main components can also use special processing methods. For example, a local reinforcement method is applied to a stressed member. These measures can reduce the dead weight of the barrier device and improve the quality utilization factor.

2.2 Select structural scheme

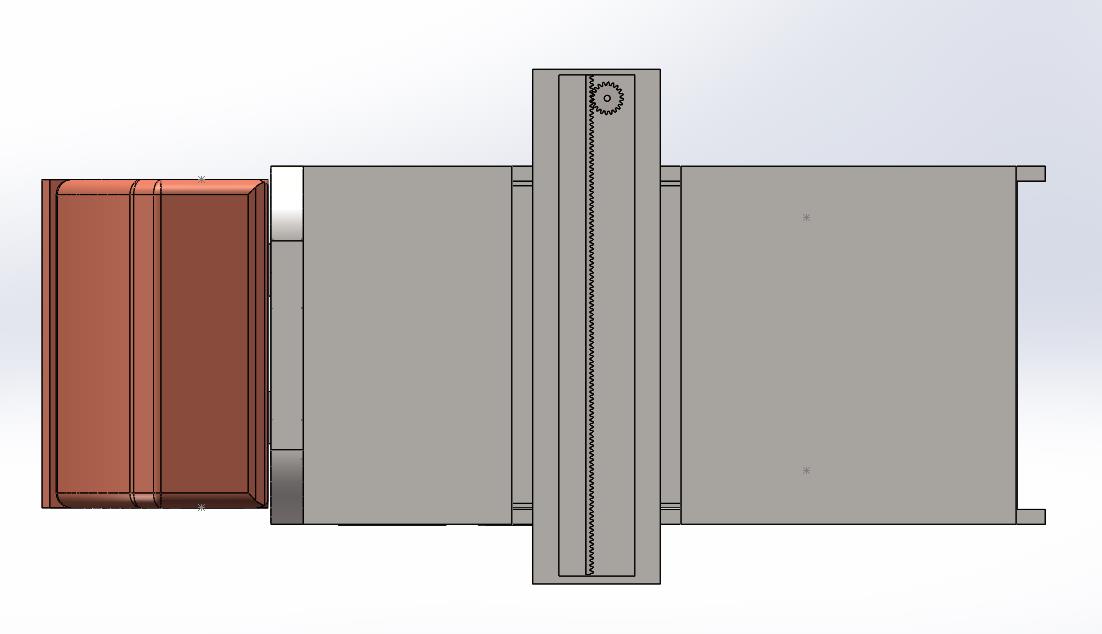

2.2.1 Horizontal slide structure scheme

The principle is that the rack and pinion mechanism can convert the rotation of the gear into the reciprocating linear motion of the rack, so a rack and pinion mechanism is set under the carriage rail and sealed to prevent the influence of oil pollution and the like. The hydraulic motor drives the gears to rotate, so that the entire lifting mechanism realizes the reciprocal sliding of the carriage on the slide rails. The advantage of this control method is that the structure is simple and easy to implement. The disadvantage is that the rack and pinion mechanism is relatively precise, and it is easily affected by external forces and causes problems in the mechanism.

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。