800kN-m塔式起重机臂架与平衡臂设计毕业论文

2020-04-15 16:47:39

摘 要

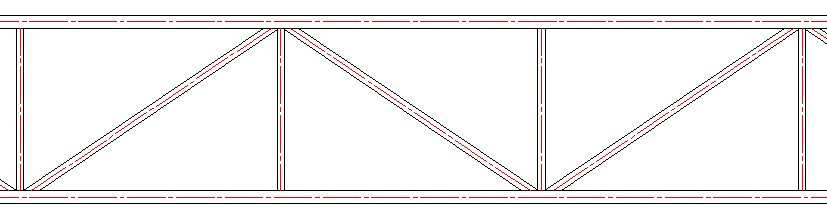

随着时间的发展,现在国内出现了一种新型的塔机,相对于塔式起重机而言,这种塔机没有拉杆和塔帽。头塔机和塔头塔机相比,在连接方式和受力方面明显不同。平头塔机的受力方面,上下弦杆的受力情况保持不变,下弦杆主要靠压应力,上弦干主要是靠拉应力,没有交变应力。基于这一特点,平头塔机的结构设计比较简单,上弦杆靠起重臂连接处来承受拉力,通过销连接;而下弦杆主要受压应力,下弦杆靠起重臂连接处端面来承受压力。当前,平头塔机主要以传统类比法和静态应力分析法进行设计,故而导致平头塔机的结构方面不合理,材料浪费,危险系数高等状况。平头塔机最显著的特点就是没有塔头和拉杆,也正是基于这一特点在很大程度上决定了它结构的优点和缺点。本次设计,以先设计再验算的思路,根据GB/T 13752-92《塔式起重机设计》,通过不同部位危险截面的许用应力来设计结构参数,再结合ANSYS有限元分析进行完善。

关键字:平头塔机 ANSYS 有限元分析 危险截面

800kN-m tower crane boom and balance arm design

Abstract

With the development of time, there is now a new type of tower crane in China. Compared with tower cranes, this tower crane has no tie rods and tower caps. Compared with the tower crane, the head tower crane is significantly different in connection mode and force. In terms of the force of the flat-head tower crane, the force of the upper and lower chords remains unchanged, and the lower chord mainly relies on compressive stress. The upper chord is mainly pulled by tensile stress and has no alternating stress. Based on this feature, the structure design of the flat-top tower crane is relatively simple. The upper chord rod is connected to the tension arm by the jib joint and is connected by the pin. The lower chord is mainly subjected to compressive stress, and the lower chord is pressed against the end of the jib joint to bear the pressure. . At present, the flat-top tower crane is mainly designed by the traditional analogy method and the static stress analysis method, which results in unreasonable structural aspects of the flat-head tower crane, material waste, and high risk factor. The most striking feature of the flat-top tower crane is that there is no tower head and tie rod, and it is based on this feature that largely determines the advantages and disadvantages of its structure. In this design, according to the idea of designing and re-checking, according to GB/T 13752-92 "Tower Crane Design", the structural parameters are designed by the allowable stress of dangerous sections in different parts, and then combined with ANSYS finite element analysis to improve.

Keywords: Flat head tower machine ; ANSYS ; Finite element analysis; Dangerous section

目录

摘要 I

Abstract II

目录 III

第一章 平头塔机的基础介绍 1

1.1平头塔机的来源 1

1.2平头塔机的主要特点 1

1.3 平头塔机在国外的发展情况 2

1.4 平塔机在国内的发展现状 3

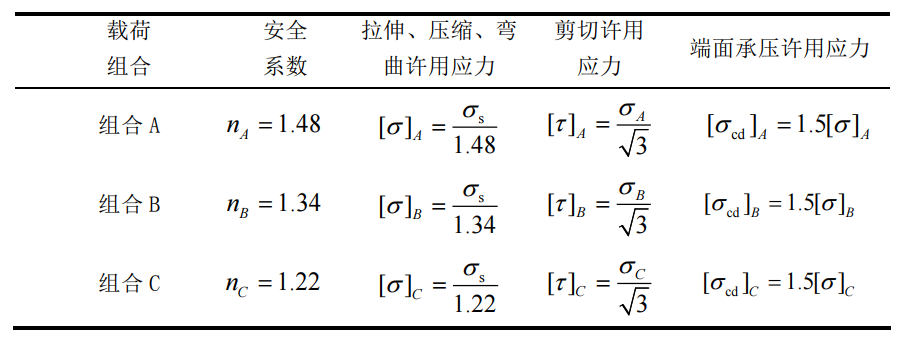

第二章 800kN平头塔机起重臂设计计算 4

2.1起吊平面内载荷计算 5

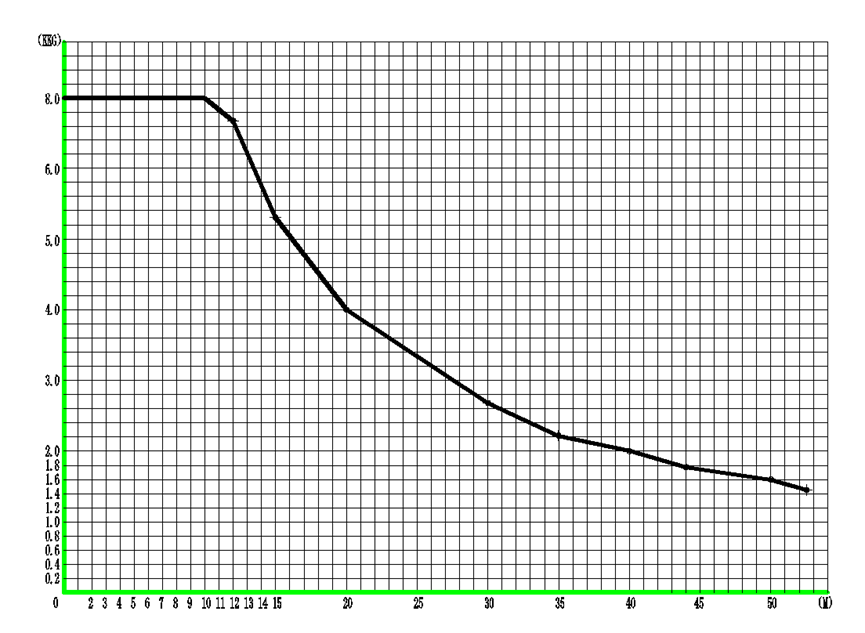

2.1.1当吊重在臂尖55 m处时 6

2.1.2当吊重在臂根10 m处时 7

2.2回转平面内载荷计算 7

2.2.1吊重回转惯性载荷计算 7

2.2.2吊具和吊重物的风载荷计算 8

2.2.3 起重臂自重回转惯性载荷计算 9

2.2.4 起重臂的风载荷计算 10

2.2.5 起重臂各计算i点总弯矩 11

2.3 吊重处在臂架尖端时各截面的参数计算 12

2.4 臂架主弦杆尺寸计算 13

2.4.1 上弦杆的尺寸计算 13

2.4.2 下弦杆的尺寸计算 14

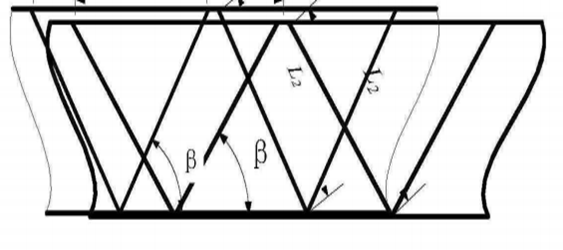

2.5斜腹杆及水平腹杆的计算 14

2.5.1 斜腹杆计算 14

第三章 起重臂的结构分析 18

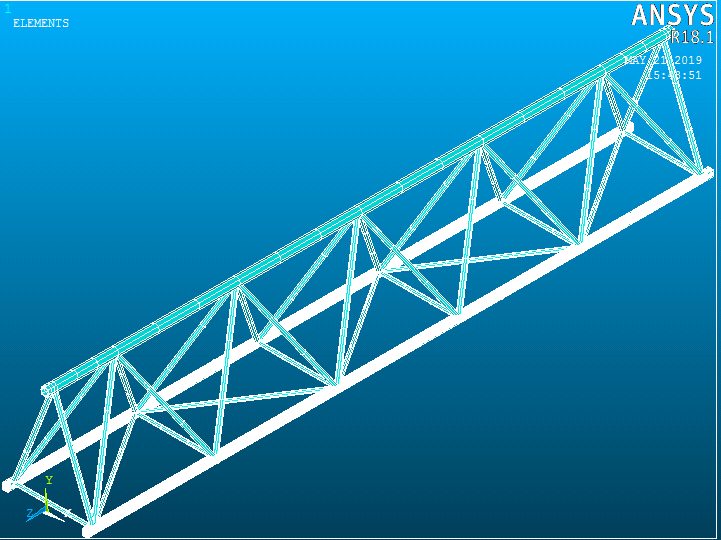

3.1 Ansys简介 18

3.2 APLD建立臂架模型 18

3.3 工况分析 23

3.3.1 工况一 23

3.3.2 工况二 25

3.3.3 工况三 27

3.3.4 工况四 29

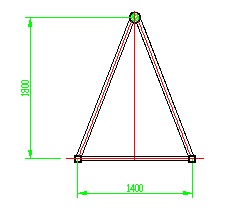

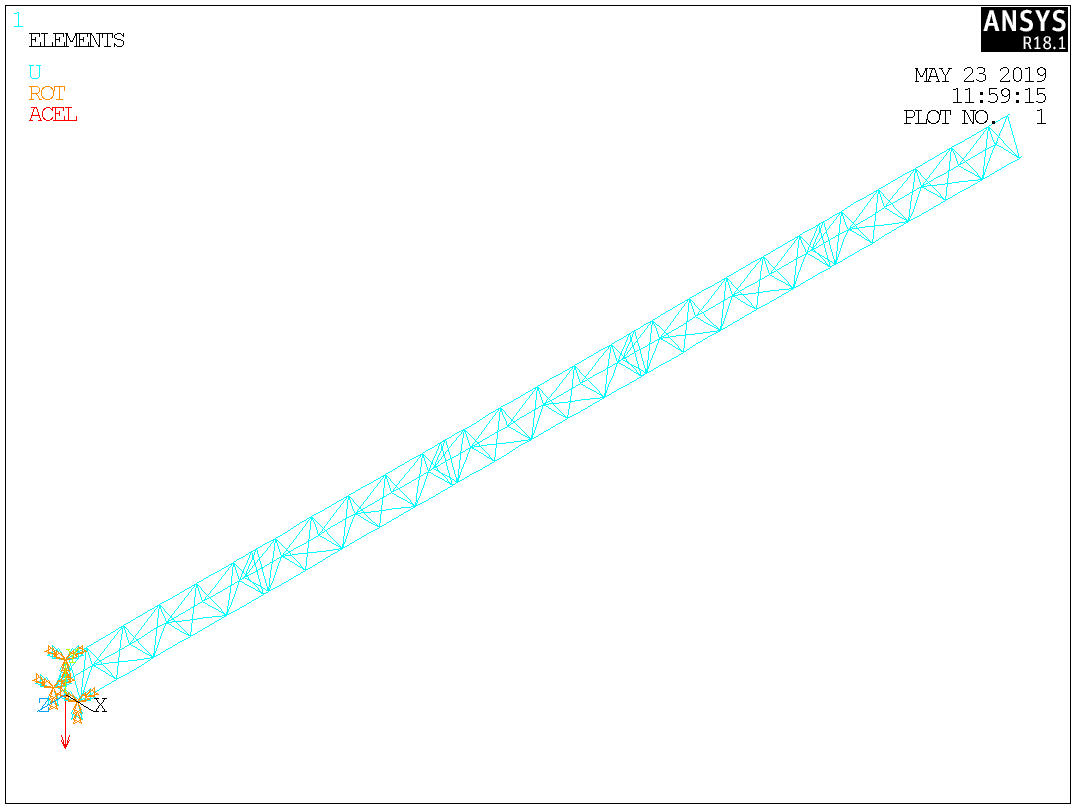

第四章 平衡臂设计及ANSYS有限元分析 32

4.1 各参数的确定 32

4.2 建立模型 33

4.3 各工况后处理 35

结论 39

参考文献 41

致谢 42

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。