微纳米玻璃棉增强热塑性聚氨酯弹性体复合材料制备与性能研究毕业论文

2020-04-15 16:56:07

摘 要

热塑性聚氨酯弹性体(TPU)制成的产品在生活中随处可见。TPU具有较高的强度和弹性,优异的耐磨性、耐油性,经过其他材料增强后制成的TPU复合材料具有各自不同的特殊性能。玻璃纤维是一种无机材料,由于隔绝温度、对高温的耐受性能强并且拉伸性能好,所以被广泛地被用作增强材料。

传统的TPU已不能满足人民的性能需求,于是我们利用微/纳米玻璃棉来增强TPU从而获得一种价格便宜但性能优异的复合材料。利用机械掺混法将微/纳米玻璃棉纤维与热塑性聚氨酯弹性体制成复合材料,通过扫描电子显微镜(SEM)和万能试验机对复合材料的微观结构、拉伸强度和断裂伸长率进行研究。此外还利用γ-氨丙基三乙氧基硅烷(KH550)对微/纳米玻璃棉纤维进行改性,与热塑性聚氨酯弹性体制成复合材料进行相同的实验。通过实验数据和结果对比发现微/纳米玻璃棉纤维改性与否都对热塑性聚氨酯弹性体具有增强作用。但未改性的微/纳米玻璃棉纤维增强作用较小,且过量微/纳米玻璃棉纤维反而会导致拉伸强度和断裂伸长率的下降。利用γ-氨丙基三乙氧基硅烷(KH550)对微/纳米玻璃棉纤维进行改性大幅度提高了微/纳米玻璃棉纤维对热塑性聚氨酯弹性体的增强作用,当改性后微/纳米玻璃棉纤维的含量为3%时,复合材料的拉伸强度相较于纯热塑性聚氨酯弹性体增加了39.7%;当改性微/纳米玻璃棉纤维含量的含量为2%时,复合材料的断裂伸长率相对于纯热塑性聚氨酯弹性体的断裂伸长率增长了27%。

关键词:玻璃棉 热塑性聚氨酯弹性体 复合材料

Preparation and Properties of Micro-Nano Glass Cotton reinforced Thermoplastic Polyurethanes Elastomer Composites

Abstract

Thermoplastic polyurethane elastomer (TPU) is a kind of material which can be seen everywhere in life,which has high strength and elasticity,excellent wear resistance and oil resistance.The TPU composites reinforced by other materials have different special properties.The glass fiber is an inorganic material,and is widely used as the reinforcing material due to the insulating temperature,high resistance to high temperature and good tensile properties.

The traditional TPU can no longer meet the performance needs of the people,so we use micro/nano glass cotton to enhance TPU to obtain a cheap but excellent composite.Micro/nano glass cotton fiber and thermoplastic polyurethane were prepared by mechanical mixing method.The microstructure,tensile strength and elongation at break of the composites were studied by scanning electron microscope (SEM) and universal testing machine.In addition,the micro/nano glass cotton fiber was modified by 3-Aminopropyltriethoxysilane(KH550),and the same experiment was carried out with thermoplastic polyurethane elastic composite.Through the comparison of experimental data and results,it is found that whether the micro/nano glass cotton fiber is modified or not,it can enhance the thermoplastic polyurethane elastomer.However,the unmodified micro/nano glass cotton fiber has little reinforcement effect,and the excessive micro/nano glass cotton fiber will lead to the decrease of tensile strength and elongation at break.The modification of micro/nano glass cotton fiber with 3-Aminopropyltriethoxysilane(KH550) greatly improved the enhancement effect of micro/nano glass cotton fiber on thermoplastic polyurethane elastomer.When the content of micro/nano glass cotton fiber is 3%,the tensile strength of the composite is 39.7% higher than that of pure thermoplastic polyurethane elastomer.When the content of modified micro/nano glass cotton fiber is 2%,the elongation at break of the composite increases by 27% compared with that of pure thermoplastic polyurethane elastomer.

Keywords: Thermoplastic Polyurethane (TPU); Micro/nano glass cotton fiber; Composite

目 录

摘 要 I

Abstract II

第一章 绪 论 1

1.1 背景与意义 1

1.2 热塑性聚氨酯弹性体 2

1.3 玻璃棉 2

1.4 国内外研究现状 2

第二章 材料制备及性能表征 6

2.1 实验材料与仪器 6

2.1.1 实验材料 6

2.1.2 实验仪器 6

2.1.3 样品制备流程 6

2.2 纤维和复合材料的表征 9

2.2.1 扫描电子显微镜(SEM) 9

2.2.2 机械性能测试(拉伸强度 断裂伸长率) 10

第三章 实验结果与讨论 11

3.1 纤维的表征 11

3.1.1 微/纳米玻璃棉性能测试分析 11

3.1.2 SEM 12

3.2 复合材料的力学性能测试分析 13

3.2.1 未改性微/纳米玻璃棉增强TPU复合材料拉伸性能分析 14

3.2.2 改性微/纳米玻璃棉增强TPU复合材料拉伸性能分析 16

第四章 成本估算 24

第五章 结论与展望 22

5.1 结论 22

5.2 展望 22

参考文献 25

致 谢 27

- 绪 论

- 背景与意义

单一材料的性能在目前越来越不能满足于人们生产生活的需求,因此由多种材料复合而成的复合材料走进人们的生活。复合材料可以将原单一材料各自的优异性能组合起来,通过两种材料的互相协作、相互配合产生与原材料不同的新性能。复合材料弱化了单一材料的劣势,其互补的作用提高了材料的性能,扩大了材料的应用范围。古代,中国的建造者修建长城时在砖块缝隙中使用加入糯米的砂浆来粘合砖块,大大提高了砖块间的粘合强度,使得长城经历了很多年的风吹雨打依然稳固。现代,人们建造房屋时在混凝土中加入钢筋来改善混凝土的力学性能,使得房屋和桥梁等建筑物更加坚固,减少危险的发生。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

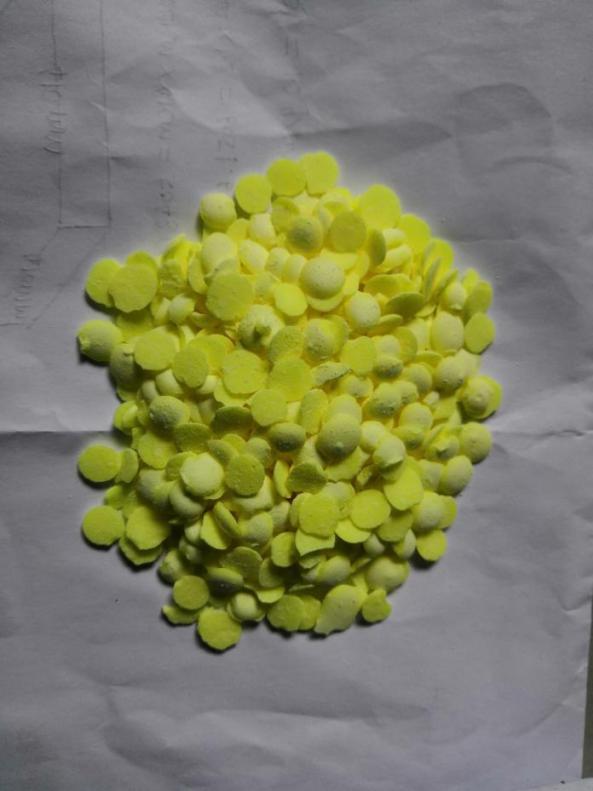

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。