吸水室内部流动分析及对泵外特性的影响研究毕业论文

2020-04-15 17:31:41

摘 要

离心泵很多情况下输送的是气液两相混合介质。本文以IS80-50-250模型泵为研究对象进行试验,采用摄像机对离心泵吸水室内气液混合流动状态进行了记录拍摄和分析,同时应用FLUENT软件模拟其内部流动并进行数值计算,研究了离心泵吸水室内气液两相流动的部分规律,并分析了不同气液相流量和转速情况下泵内部流动对外特性的影响。研究可为高性能两相流泵的开发提供参考。本文的研究内容和结论如下:

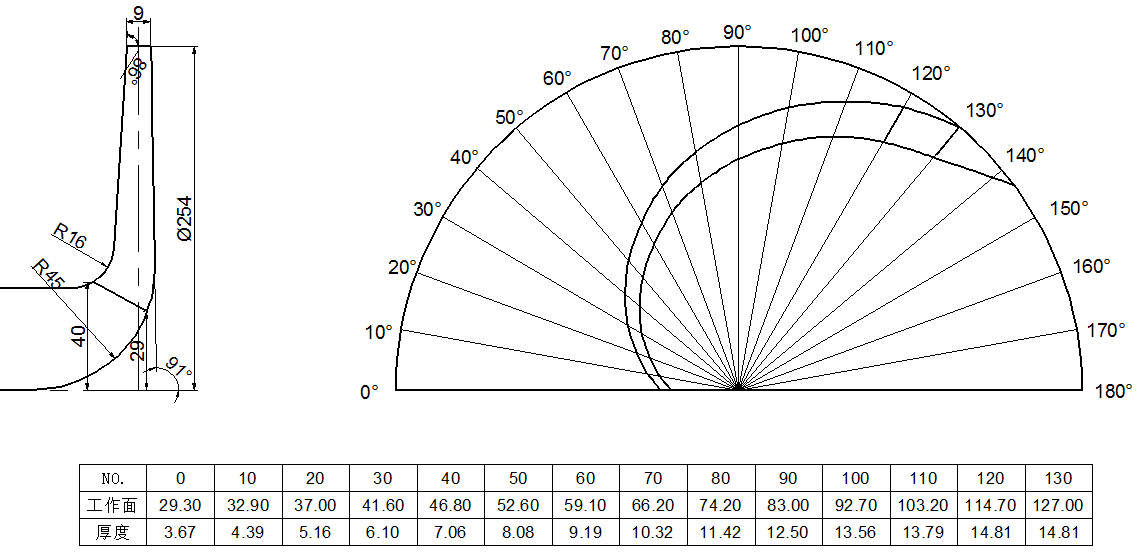

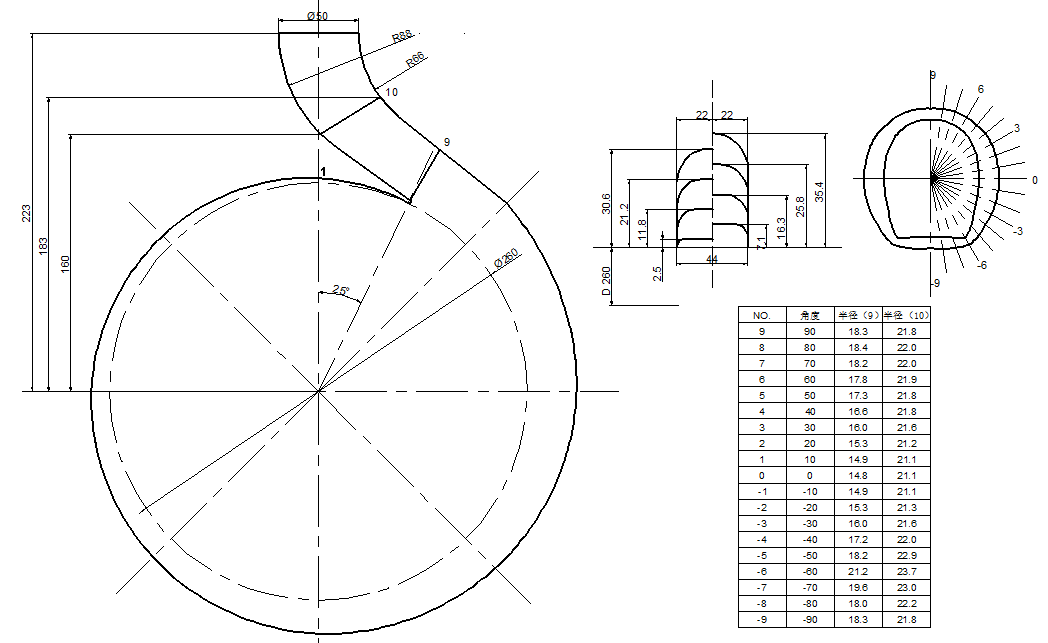

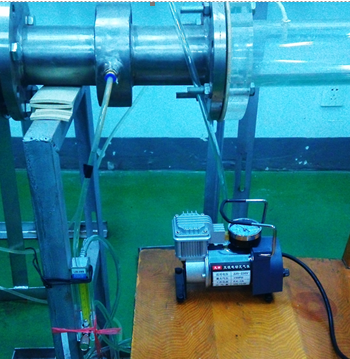

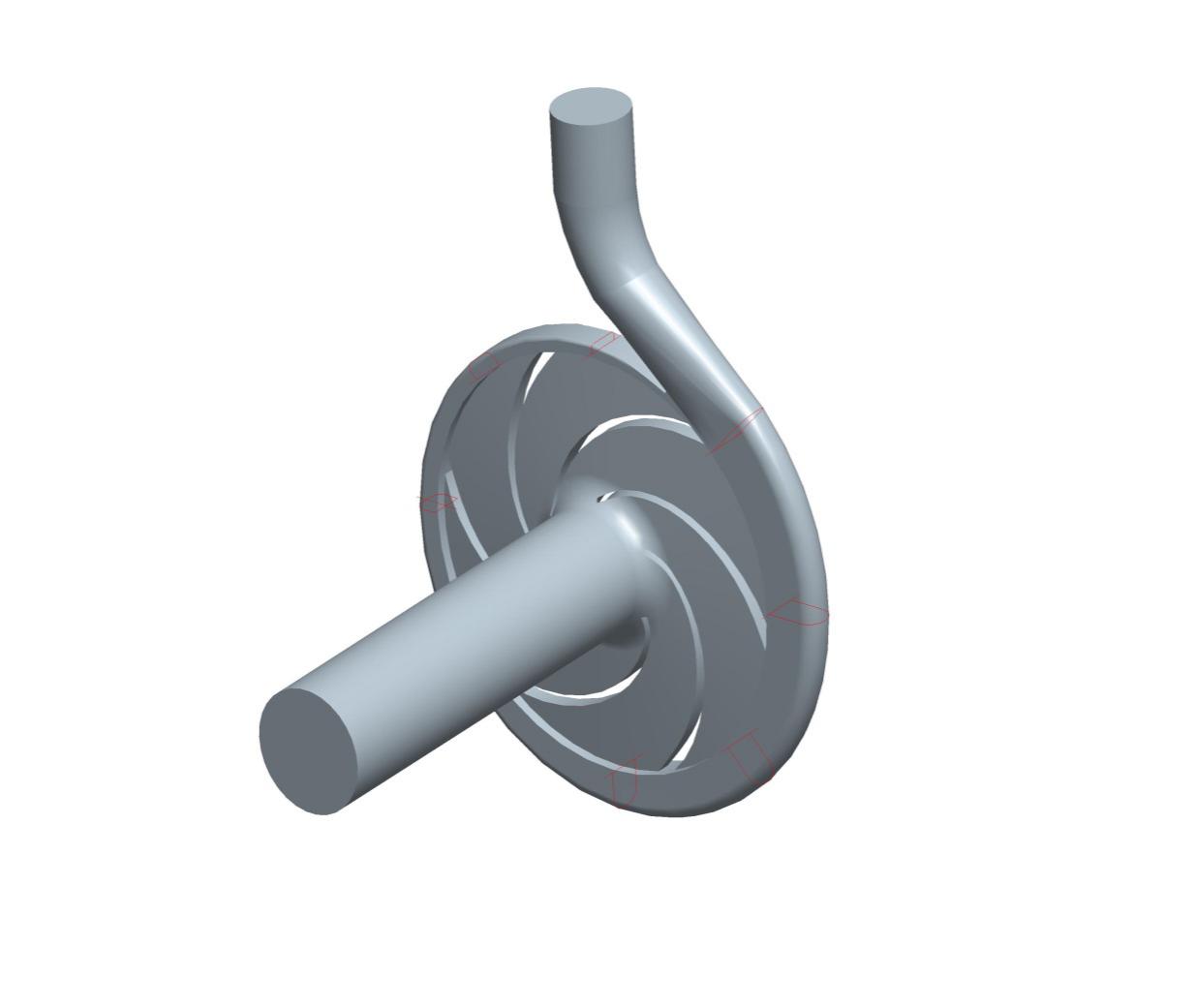

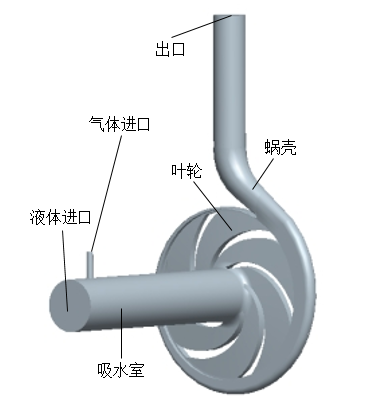

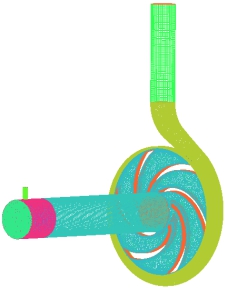

(1)为实现对离心泵内部流动的测量,采用摄像机拍摄有机玻璃模型泵内部流动。同时对IS80-50-250型离心泵进行了三维建模与数值计算,针对本文所涉及的离心泵气液两相流问题,确定了求解过程中所需要的各种参数。

(2)对离心泵内部气液两相流动进行试验与数值模拟,分析了液相流量、气相流量和泵转速对吸水室内流型的影响。结果表明:影响吸水室内流型的因素主要有液体流量Ql、气体流量Qg和泵转速n。其中,液体流量Ql和气体流量Qg对流型变化的影响较大,而泵转速n的影响较小,在液体流量较大的工况下,转速对吸水室内流型几乎没有影响。

(3)分析了气相在不同工况下的速度分布、液相在吸水室出口处截面的速度分布和吸水室内部压力分布情况。结果表明:由于吸水室上壁面处的影响,吸水室内气体在轴线上的圆周分速度,从进口至接近出口处速度几乎为零,而在靠近叶轮进口处,气体受到螺旋作用,速度大幅增大。且在不同工况下变化相似。吸水室出口处截面的速度分布,主要受到液相流量的影响,改变气相流量对速度改变不大。吸水室进口至吸水室出口压力逐渐减小,在出口处,不同气相流量或液相流量情况下,压力会出现大幅度降低,呈现出不规则的压力变化。

(4)研究了气相流量、液相流量和转速对离心泵扬程和水力效率的影响。结果表明:当液体流量小于转速对应的额定流量时,随液相流量增加,离心泵扬程增大,水力效率先增加后减小。保持液相流量不变,随着气相流量增大,离心泵扬程小幅度降低,水力效率基本维持在一定范围。转速改变则对离心泵外特性影响显著,当转速增加,扬程有明显的增大,水力效率有明显的减小。

关键词:离心泵 吸水室 数值模拟 气液两相流型 外特性

Flow analysis of suction chamber and

influence of pump characteristics

Abstract

In many cases, centrifugal pumps transport gas-liquid two-phase mixing media. In this dissertation, the IS80-50-250 model pump was selected as the research object, and the FLUENT software was used to simulate the internal flow. At the same time, the camera was used to photograph and analyze the gas-liquid two-phase flow in the suction chamber of the centrifugal pump. The law of gas-liquid two-phase flow in the suction chamber of centrifugal pump was studied, and the influence of different gas-liquid flow rates and rotational speeds on the external characteristics of the pump internal flow was analyzed. The research can provide reference for the development of high-performance two-phase flow pump. The research contents and conclusions of this dissertation are as follows:

(1) In order to measure the internal flow of the centrifugal pump, a camera was used to photograph the internal flow of the Organic glass model pump. At the same time, three-dimensional geometrical modeling was built, and the numerical calculation of IS80-50-250 centrifugal pump was performed. Aiming at the gas-liquid two-phase flow problem of the centrifugal pump, various parameters needed in the solution process were determined.

(2) The gas-liquid two-phase flow in centrifugal pump was tested and simulated. The effect of liquid flow rate, gas flow and pump rotational speed on the flow pattern was analyzed. The results show that the main factors affecting the flow pattern in the suction chamber are liquid flow rate Ql, gas flow rate Qg and pump speed n. Among them, the influence of liquid flow rate Ql and gas flow rate Qg on the flow pattern change is great, while the influence of pump speed is small. In the liquid flow rate working conditions, high rotational speed will have little impact on the suction pipe flow pattern.

(3) The velocity distribution of gas phase under different working conditions, the velocity distribution of liquid phase at the exit of the suction chamber and the pressure distribution inside the suction chamber were analyzed. The conclusion shows that the influence of the upper wall of the suction chamber, the circumferential velocity of the gas in the suction chamber on the axis is almost zero from the inlet to the outlet. while the velocity of the gas in the suction chamber is greatly increased by the spiral action near the impeller inlet. The variation is similar under different working conditions. The velocity distribution at the outlet of the suction chamber is mainly influenced by the liquid flow rate, and the change of gas flow rate has little effect on the velocity. The pressure decreases gradually from the inlet of the suction chamber to the outlet of the suction chamber. At the outlet, the pressure decreases dramatically at different gas or liquid flow rates, presenting irregular pressure changes.

(4) The influence of gas flow rate, liquid flow rate and rotational speed on the and the head and hydraulic efficiency of the centrifugal pump was studied. Results show that when the liquid flow rate is less than the rated flow corresponding to the rotational, with the increase of liquid flow rate, the head of the centrifugal pump will increase, and the hydraulic efficiency increases first and then decreases. With the increase of gas flow rate, the head of the centrifugal pump decreases slightly, and the hydraulic efficiency is basically maintained in a certain range. The rotational speed had a great effect on the external characteristic of centrifugal pump. with the increase of rotational speed, the head increases obviously, and the hydraulic efficiency significantly.

KEYWORDS: Centrifugal pump; Suction chamber; Numerical simulation; Gas-liquid two-phase flow pattern; External characteristics

目 录

第一章 绪论 1

1.1 研究背景和意义 1

1.1.1 研究背景 1

1.1.2 研究意义 2

1.2 研究现状及发展趋势 2

1.2.1 吸水室内部流动试验研究 2

1.2.2 吸水室内部流动数值计算 3

1.3 研究内容 4

1.3.1 吸水室内部流动试验研究 4

1.3.2 吸水室内部流动数值计算研究 4

1.4 研究方法 4

1.4.1 吸水室内部流动分析试验研究方法 4

1.4.2 吸水室内部流动数值计算研究方法 5

1.4.3 吸水室内部流动与泵外特性分析方法 5

第二章 离心泵内部气液两相流动试验 6

2.1 试验装置 6

2.1.1 离心泵试验台 6

2.1.2 模型泵 7

2.1.3 离心泵输送和采集系统 9

2.2 试验内容和方法 10

2.2.1 试验内容 10

2.2.2 拍摄方法 10

2.2.3 试验方案 11

2.3 离心泵内部气液两相流试验结果与分析 11

2.3.1 流型与液体流量Ql的关系 11

2.3.2 流型与气体流量Qg的关系 13

2.3.3 流型与泵转速n的关系 15

2.3.4 吸水室内流型图谱 16

2.4 本章小结 17

第三章 数值模拟方法 18

3.1 模型构建 18

3.1.1 Pro/E三维建模软件简介 18

3.1.2 几何模型 18

3.2 ICEM网格划分 19

3. 3 计算方法 20

3.3.1 基本方程 20

3.3.2 湍流模型 20

3.3.3两相流模型 21

3.4 边界条件 22

3.5 本章小结 22

第四章 吸水室内部数值模拟结果分析 23

4.1 吸水室内流型 23

4.1.1 螺旋泡状流型 23

4.1.2 螺旋塞状流型 24

4.1.3 稳态泡状流型 25

4.1.4 稳态塞状流型 26

4.1.5 脉动泡状流型 27

4.1.6 脉动塞状流型 28

4.2 吸水室内速度分布 28

4.2.1 气体在轴线方向上的速度分布 28

4.2.2 吸水室出口处速度分布 32

4.3 吸水室内压力分布 35

4.4 本章小结 39

第五章 离心泵外特性数值模拟研究 40

5.1 液相流量对泵外特性的影响 40

5.2 气相流量对泵外特性的影响 42

5.3 转速对泵外特性的影响 44

5.4 本章小结 46

第六章 结论与展望 47

6.1 结论 47

6.2 展望 48

参考文献 49

致谢 52

第一章 绪论

1.1 研究背景和意义

1.1.1 研究背景

原动机的机械能转化成传送流体的动能和压能这个过程离不开离心泵,它的作用是对被传送流体做功,使其能量增加。离心泵属于流体机械,是目前在工业生产、农业生产、城乡给水和排水等方面使用最为广泛的加压设备。因此,离心泵在国民经济建设发展中扮演着重要的角色[1,2],与它相关的使用性能也逐渐成为了研究的重点。

离心泵的使用性能受到内部流动影响,如何改善泵内流动是设计离心泵的关键[3]。水泵作用的发挥与吸水室的结构密切相关,目前,比较常见的吸水室结构形式有直锥吸水室、半螺旋吸水室和圆环吸水室等[4]。

直锥形吸水室因其简单的结构,在农业生产中被广泛的应用[5]。直锥形吸水室能将液体的压力损失降到非常低,且在叶轮进口前的压力较小,从而能保证叶轮内流场均匀。吸水室内部同时存在径向漩涡和轴向旋涡,其流动状态与流量、位置及边界条件有关。通过比较可得出,平直吸水室内部的流动状态最佳[6]。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。