精馏塔冷凝器设计毕业论文

2020-04-15 17:40:17

摘 要

人类进入工业化时代以来,对能源的需求日益增加,由于传统能源的不可再生性,近些年来能源短缺带来的影响逐渐明显。为解决有限能源与无限需求之间的矛盾,开源节流显得尤为重要。目前依托技术的革新,对太阳能、风能、地热能、核能等新型能源的开发利用缓解了日益严重的能源问题,但目前我国的能源消耗量巨大,且能源转换率较低,从“节流”方面而言提高能源的综合利用率,进而实现节能降耗,未尝不是一种行之有效的方法。

在能源的开发利用过程中需要用到很多设备,但相对而言换热器无疑是其中最为重要的能源转换利用设备之一,其在能源的开发利用过程中扮演着举足轻重的作用,几乎一切化工乃至整个工业领域都需要它的参与,此外,在冶金、动力、航空航天、交通运输等行业领域其应用也十分广泛。因此,汲取前人的工程实践经验,并结合国家标准中的相关规定和要求,对换热器进行合理的材料选取、工艺计算、结构设计具有十分重要的意义。

本文介绍了过程工业中最为常用的换热器——固定管板式换热器的设计方法。作为精馏工艺的重要设备,塔顶冷凝器的运行状况决定了整个工艺能否稳定运行及生产产品质量的优劣,因此合理的结构设计显得尤为重要。固定管板式换热器结构简单,制造成本较低,且其相对换热面积较大,运行较为可靠。因此,本次设计选用固定管板式换热器作为精馏塔顶冷凝器。

首先,遵循工艺流程,以生产要求为依据对精馏塔进行了物料衡算,进而确定了塔顶冷凝器的操作工况;而后,依据操作工况对所需换热面积、换热管数、流体压降及总传热系数进行了计算校核;在上述设计的基础上,依据中径公式和设计条件,对整个换热器的筒体厚度、管箱几何尺寸进行了设计计算;最后,依据工程实践经验及国家标准对换热器的进出口管尺寸位置及外伸长度、换热管排布方式、支座形式、法兰形式、折流板形状尺寸及排布规则等相应参数进行了确定。

此外,在常规设计完成后以SW6软件对整个换热器的强度进行了校核计算,校核结果表明设备设计合格。在文章的工艺计算部分,对设备的工艺校核也顺利通过,证明精馏塔顶冷凝器的设计是合理的。

关键词:换热器 固定管板 精馏塔

Design of Condenser for Distillation Column

ABSTRACT

Since the human race into the industrial era, the demand for energy is increasing, because of the non-renewable nature of traditional energy sources, the impact of energy shortage in recent years has gradually become apparent. In order to solve the contradiction between limited energy and infinite demand, it is very important to cut expenditure. At present, relying on the innovation of technology, the growth and utilization of new energy resources such as solar, wind, geothermal and nuclear energy have alleviated the increasingly serious energy problems, but at present, China's energy consumption is huge, and the energy conversion rate is low, from the "throttling" aspect to improve the comprehensive utilization rate of energy, and then achieve energy saving and consumption reduction, It’s an effective method.

In the process of energy development and utilization, a lot of equipment is needed, but relatively speaking heat exchanger is undoubtedly the most important energy conversion and utilization equipment, it plays a key role in the process of energy development and utilization, almost all chemicals and even the entire industrial sector need its participation, in addition, in metallurgy, power, aerospace, Transportation and other industries in the field of its application is also very extensive. Therefore, it is of great significance to make reasonable material selection, process calculation and structure design for heat exchanger by drawing on the previous engineering practical experience and combining the relevant regulations and requirements in the national standard.

This paper introduces the design way of fixed tube plate heat exchanger, which is the most commonly used in process industry. As an important equipment of distillation process, the operation condition of tower top condenser determines whether the whole process can run stably and the quality of production products, so reasonable structure design is very important. The fixed tube plate heat exchanger has the simple structure, low manufacturing cost, and its relative heat transfer area is large, and the operation is more reliable. Therefore, this design selects the fixed tube plate heat exchanger as the distillation tower top condenser.

First of all, follow the process flow, based on the production requirements of the equipment determine the operating conditions of the tower top condenser, and then, according to the operating conditions of the required heat transfer area, heat exchanger number, fluid pressure drop and total heat transfer coefficient of the calculation and verification; On the basis of the above design, The cylinder thickness and the geometric size of the pipe box of the whole heat exchanger are designed and calculated, and finally, according to the engineering practice and national standards, the corresponding parameters such as the size position and extension length of the import and export pipe, the arrangement mode, the bearing form, the flange form, the shape size of the folding plate and the arrangement rules are determined.

In addition, after the general design is completed, the strength of the whole heat exchanger is checked and calculated with SW6 software, and the checking results show that the equipment is designed to be qualified. In the process calculation part of the article, the process check of the equipment is also successfully passed, which proves that the design of the condenser at the top of the distillation tower is reasonable.

Key Words: Heat exchanger; Fixed tube sheet; Distillation column

目 录

摘 要 I

ABSTRACT III

目 录 V

第一章 绪论 1

1.1 冷凝器的研究意义 1

1.2 换热器研究现状 2

第二章 冷凝器工艺计算 5

2.1 物料衡算 5

2.1.1 生产要求 5

2.1.2 用摩尔分率计算进料量F及塔底采出量W 5

2.1.3塔内物料衡算表 6

2.1.4 最小回流比的确定 6

2.1.5 冷凝器物料衡算 7

2.1.6 冷凝器物料衡算表 9

2.2 冷凝器热量衡算 9

2.2.1 确定物性数据 9

2.2.2 热流量 10

2.2.3 估算换热器传热面积 10

2.3确定换热管 11

2.3.1选择流体流径 11

2.3.2 冷凝器的相关数据 11

2.3.3 初选管程数及单管长度 11

2.4 工艺的结构尺寸 12

2.4.1 筒体直径计算 13

2.4.2折流板选取 13

2.4.3 接管 14

2.5 换热器核算 15

2.5.1 计算换热器管、壳程传热系数 15

2.5.2 总传热系数 17

2.5.3 传热面积核算 18

2.6冷凝器内流体阻力 18

2.6.1 管程流体阻力 18

2.6.2 壳程流体阻力 19

第三章 结构设计与强度计算 21

3.1 换热器壳程结构尺寸设计 21

3.1.1 筒体壁厚计算 21

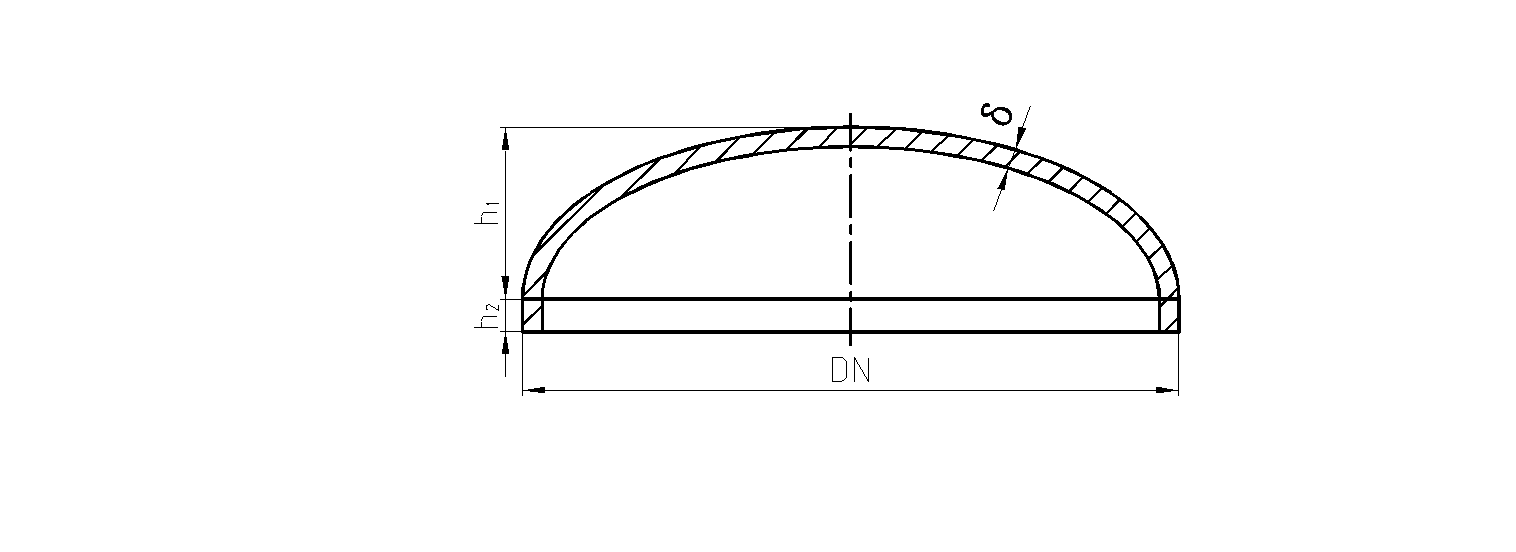

3.1.2 壳体、短节和封头结构尺寸及质量 26

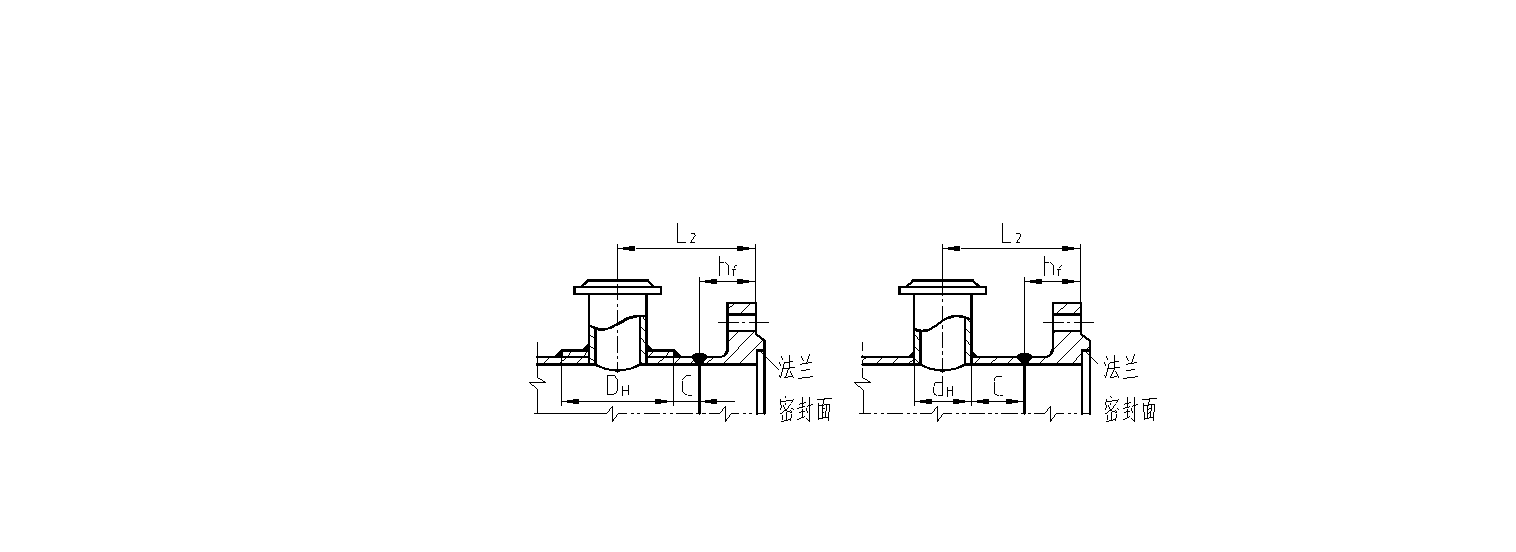

3.2 接管及法兰等相关参数选取 27

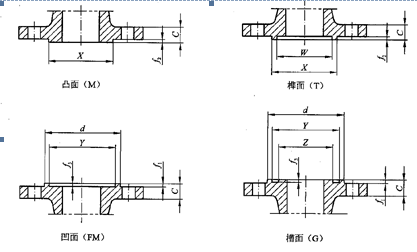

3.2.1 接管法兰与垫片选取 27

3.2.2 容器法兰与垫片的选取 28

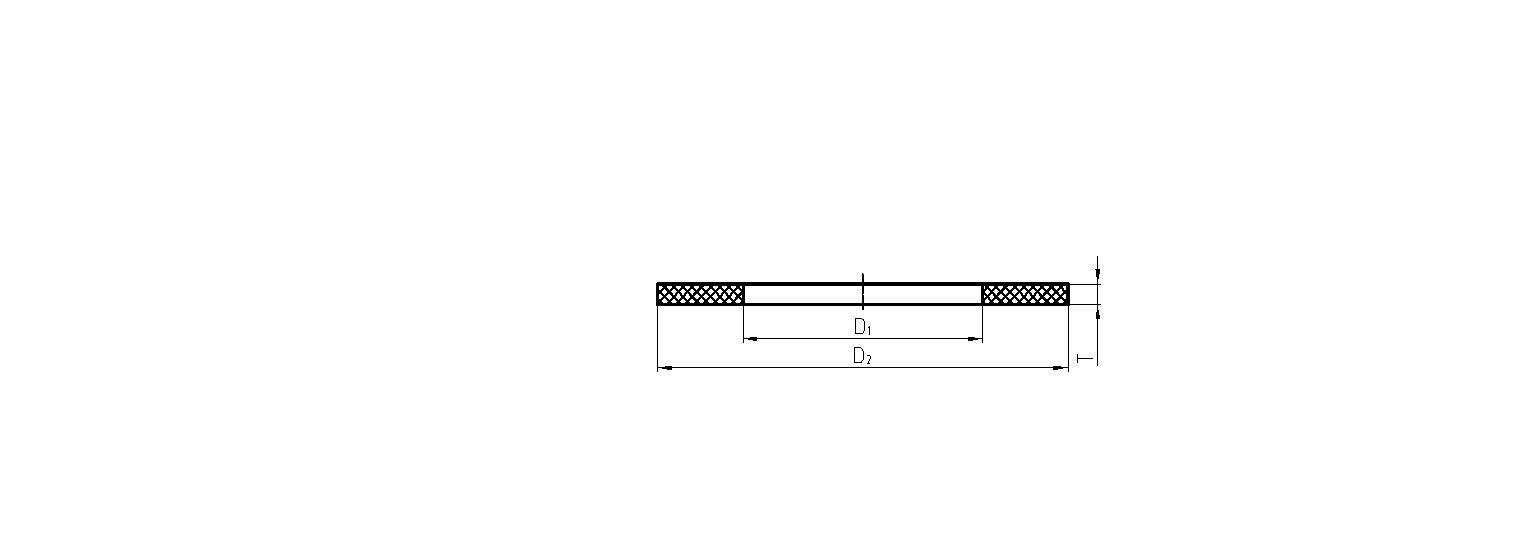

3.3 管板 29

3.4 进出口设计 30

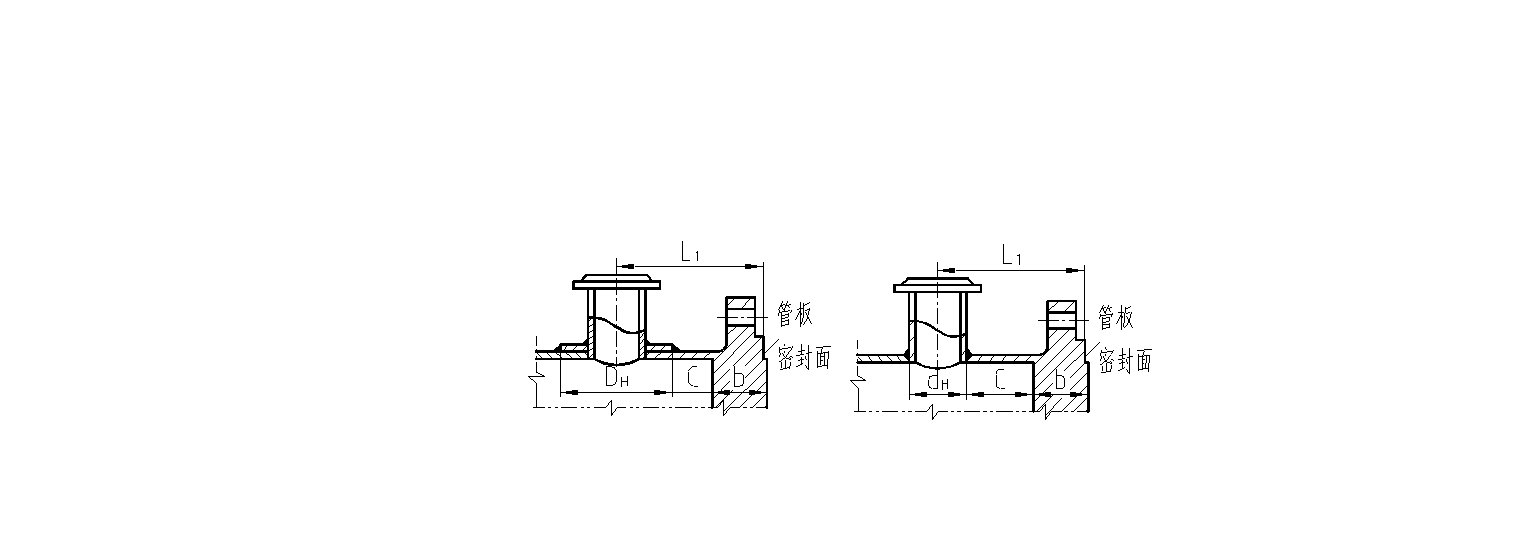

3.4.1 接管外伸长度 30

3.4.2 接管开孔补强计算 31

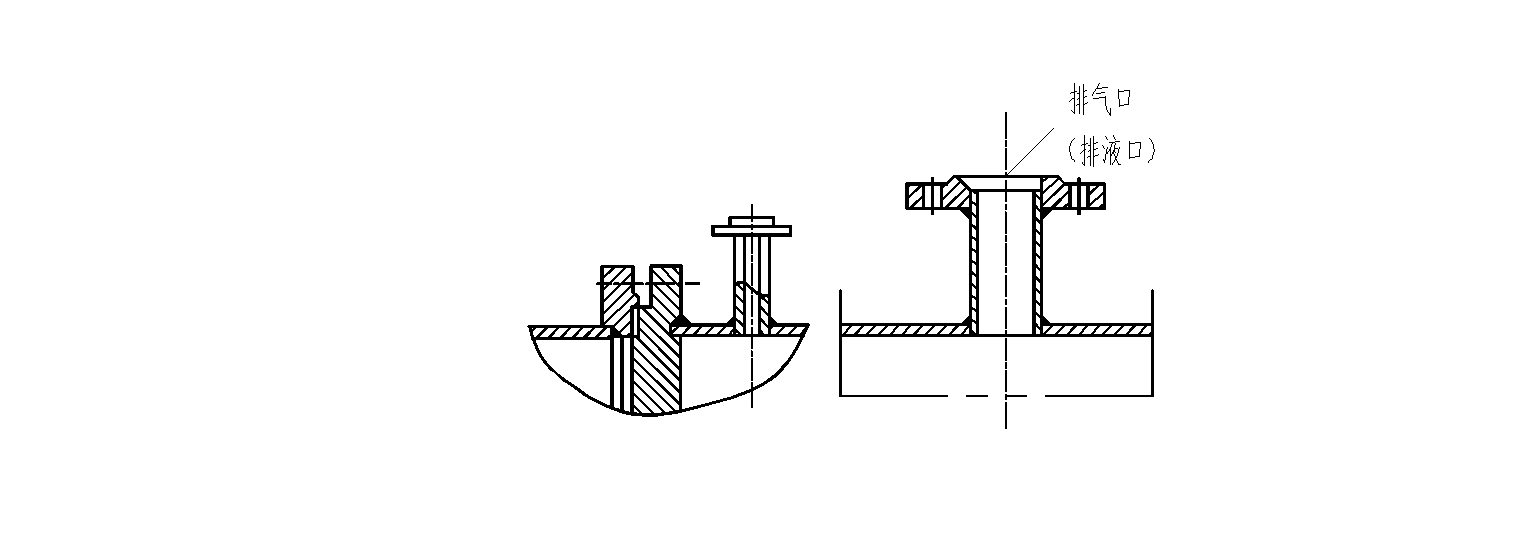

3.4.3 排气管、排液管 34

3.4.4 接管最小位置 35

3.5 换热管 37

3.5.1 换热管及中心距 37

3.5.2 换热管排列形式 37

3.5.3 布管限定圆 38

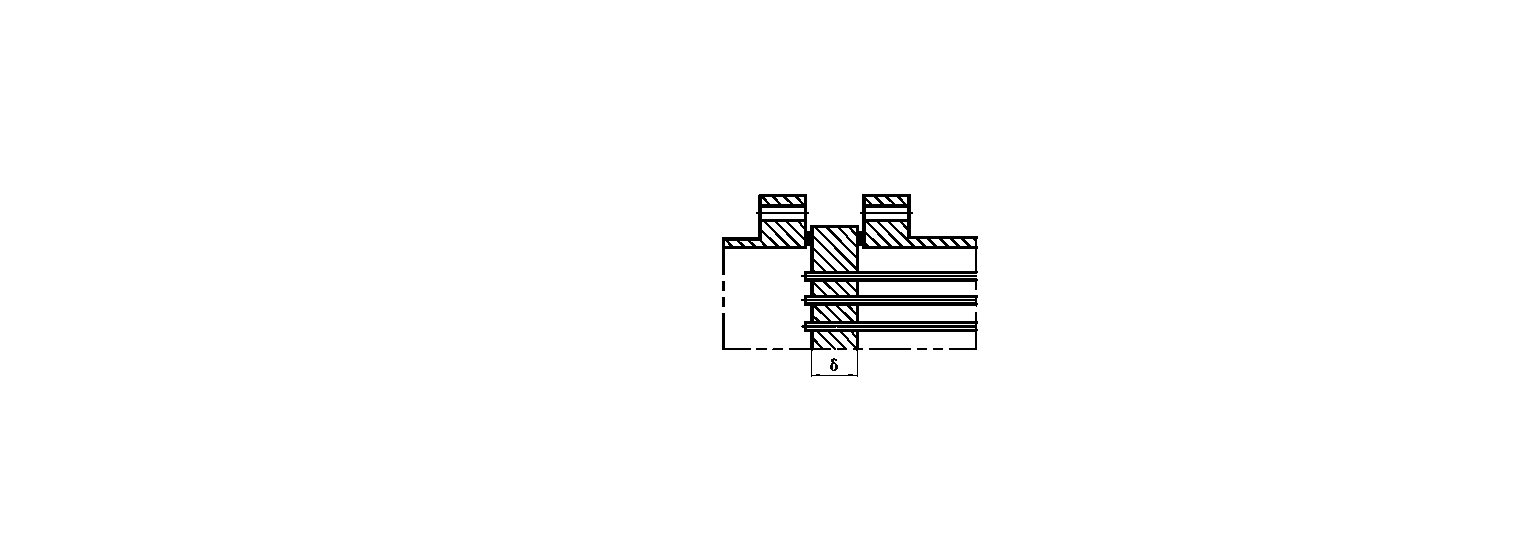

3.6 管子与管板的连接 39

3.7 其他各部件结构 40

3.7.1 膨胀节 40

3.7.2 折流板 40

3.7.3 防冲与导流 41

3.7.4 拉杆 43

3.7.5 定距管 43

3.7.6 鞍座 44

第四章 经济性评价 45

第五章 总结及展望 47

5.1 总结 47

5.1.1 塔顶冷凝器工艺计算 47

5.1.2 塔顶冷凝器压强降的校核 47

5.1.3 塔顶冷凝器结构设计 47

5.1.4 折流板设计 47

5.1.5 换热器质量 47

5.1.6 换热器其他结构确定 47

5.2 展望 47

参考文献 49

致 谢 51

第一章 绪论

1.1 冷凝器的研究意义

近些年来,中国经济处于持续高速发展状态,国内生产总值(GDP)在世界各国排名中名列前茅。但就单位GDP耗能而言,我国依旧处于较高水平,不符合绿色环保、可持续发展的理念。在这种情形下,降低单位GDP耗能显得尤为重要。

随着我国工业化进程的不断加快,石油化工,电力以及煤化工等行业大量兴起,快速发展的工业极大的带动了经济的增长,提高了人民的生活水平,尤其是石油化工行业与我们的生活息息相关。“三传一反”是石油化工和炼油等生产过程的显著特点,动量、质量、热量传递外加化学反应构成了整个化工行业。在进行上述传递和反应的过程中需要众多设备,其中塔设备占据了相对重要的位置。实际生产中使用的塔设备种类较多,包括填料塔、板式塔等,其多用于精馏、吸收、萃取等过程[1]。塔设备中主要进行质量传递过程和热量传递过程,气液或者液液在精馏塔内通过对流以及精馏塔的内件达到充分接触的效果,从而实现气液或者液液之间传热、传质的目的[2]。

精馏工艺是塔设备的典型应用场所,其操作能耗较高,约占整个工艺过程能耗的50%,如此高的耗能在带来经济效益的同时也对环境产生了巨大影响。为响应国家节能减排的政策,提高精馏塔能源利用率,降低精馏塔耗能,对改善环境质量和维持可持续发展具有十分重要的意义。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。