原油蒸馏装置中和缓蚀剂的缓蚀性能研究毕业论文

2020-04-20 13:50:54

摘 要

近年来,随着原油劣质化的趋势越来越明显,我国炼化企业原油加工中高酸、高硫原油所占的比例越来越大,总体加工量也在不断增加。从常减压蒸馏装置运行情况看,装置的腐蚀主要表现为低温部位H2S-HCl-H2O腐蚀和高温部位的硫腐蚀和环烷酸的腐蚀。本实验采用旋转挂片失重法,控制变量,来测定缓蚀剂在H2S-HCl-H2O的腐蚀环境中不同时间、pH值、温度、盐酸浓度、挂片转速、缓蚀剂浓度的缓蚀效果。通过研究分析,此缓蚀剂适用的pH值应该为5-6时缓蚀效果最佳,缓蚀率为87.59%;温度不宜过高,30℃时缓蚀效果最好,缓蚀率为94.67%;为转速不宜过快,100r/min时仅仅只有49.4%;盐酸浓度不能太高,800mg/L缓蚀率最高,为91.66%;采用高浓度缓蚀剂,缓蚀剂浓度在150mg/L时缓蚀率高达97.67%;缓蚀剂缓蚀效果有一定时间限度,此实验用的缓蚀剂在5h时缓蚀率为80.90%,6h后下降迅速,降到46.4%,因此要及时添加缓蚀剂来防止缓蚀剂失效造成设备腐蚀。

关键词:常减压蒸馏装置 中和剂 腐蚀 缓蚀剂 缓蚀性能

Study on corrosion inhibition performance of neutralizing corrosion inhibitor in crude Oil Distillation Unit

Abstract

In recent years, with the trend of crude oil deterioration becoming more and more obvious, the proportion of high acid and high sulfur crude oil in crude oil processing of refining and chemical enterprises in China is increasing, and the overall processing volume is also increasing. According to the operation of atmospheric and vacuum distillation unit, the corrosion of the unit is mainly H2S-HCl-H2O corrosion at low temperature, sulfur corrosion and Naphthenic acid corrosion at high temperature. Through research and analysis, when the suitable pH value of this corrosion inhibitor is 5-6, the corrosion inhibition effect is the best, and the corrosion inhibition rate is 87.59%. Temperature should not be too high, 30℃ corrosion inhibition effect is the best, corrosion inhibition rate of 94.67%; Is not too fast, only 49.4% at 100r/min; The concentration of hydrochloric acid should not be too high, 800mg/L corrosion inhibition rate was the highest, 91.66%. Adopting high concentration corrosion inhibitor, the corrosion inhibition rate is as high as 97.67% when the concentration of corrosion inhibitor is 150mg/L. The corrosion inhibition effect of corrosion inhibitor has a certain time limit. The corrosion inhibition rate of the corrosion inhibitor used in this experiment is 80.90% at 5h and decreases rapidly to 46.4% after 6h. Therefore, corrosion inhibitor should be added in time to prevent the failure of corrosion inhibitor and cause corrosion of equipment.

Key words: atmospheric and vacuum distillation unit;neutralizer;corrosion;corrosion inhibitor;slow release performance

目录

摘 要 I

Abstract II

第一章 文献综述 1

1.1 蒸馏装置系统的腐蚀状况 1

1.1.1腐蚀成因 1

1.1.2腐蚀机理 2

1.1.3腐蚀部位 3

1.1.4防腐措施 3

1.2 缓蚀剂的研究进展 4

1.2.1中和剂 4

1.2.2中和缓蚀剂 4

1.3 本课题研究的目的、意义及发展趋势 5

1.3.1研究的目的及意义 5

1.3.2发展趋势 6

第二章 实验部分 7

2.1 实验概述 7

2.1.1实验预想 7

2.1.2方法概要 7

2.2 实验试剂、仪器和装置 8

2.2.1实验试剂 8

2.2.2实验仪器和装置 8

2.2.3实验准备 9

2.3实验内容 10

2.3.1腐蚀介质的pH值对缓蚀剂的缓蚀率影响 10

2.3.2温度对缓蚀剂的缓蚀率影响 10

2.3.3挂片的转速对缓蚀剂的缓蚀率影响 10

2.3.4时间对缓蚀剂的缓蚀率影响 11

2.3.5缓蚀剂浓度对缓蚀剂的缓蚀率影响 11

2.3.6腐蚀介质的盐酸浓度对缓蚀剂的缓蚀率影响 11

第三章 结果与讨论 13

3.1腐蚀介质的pH值对缓蚀剂的缓蚀率影响 13

3.2温度对缓蚀剂的缓蚀率影响 14

3.3挂片的转速对缓蚀剂的缓蚀率影响 14

3.4时间对缓蚀剂的缓蚀率影响 15

3.5缓蚀剂浓度对缓蚀剂的缓蚀率影响 16

3.6腐蚀介质的盐酸浓度对缓蚀剂的缓蚀率影响 17

第四章 结论与展望 19

4.1结论 19

4.2展望 19

参考文献 20

致谢 23

第一章 文献综述

1.1 蒸馏装置系统的腐蚀状况

1.1.1腐蚀成因

腐蚀的大多数原因是蒸馏装置介质中,一些酸性物质在一定条件下对金属质地发生了一系列作用[1],作用的原理包括电化学腐蚀、、点蚀、浓差腐蚀、垢下腐蚀、缝隙腐蚀、应力及液体撞击等。原油蒸馏装置“三顶”冷却系统冷凝发生氧化的原因是由于原油中水冷凝后含有HCl、H2S等。HCl、H2S来自油气中氯化物和硫化物,与水形成H2S-HCl-H2O[2]。

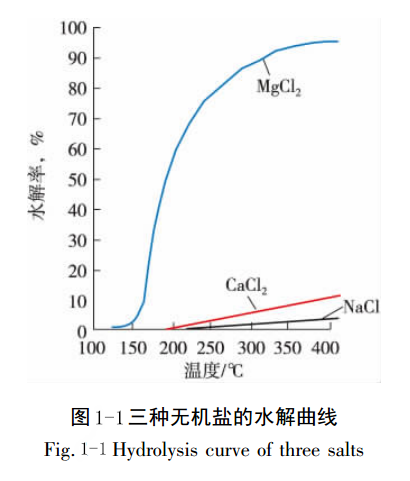

无机氯和有机氯在大部分油气是氯化物。无机氯盐在原油中主要有NaCl、MgCl2和CaCl2,有NaCl比较稳定[3],其中MgCl2和CaCl2分别在120℃和200℃左右开始发生水解,三种无机氯盐表现为,在高温时大约95%左右MgCl2和10%左右CaCl2发生水解。上述三种无机盐在见图1-1[4]。

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。