陶瓷膜分离用于制备低乳糖牛奶的研究毕业论文

2020-04-20 13:52:00

摘 要

近年来随着国民经济收入的不断提高,有机奶、低脂奶成为了市场的热销产品。传统的低乳糖牛奶生产技术主要是通过在牛奶中添加乳糖酶来分解乳糖,然而这种技术生产的低乳糖牛奶实际的糖含量并没有减少。在乳制品加工中,膜分离技术具有对环境污染小,能耗低、无需使用添加剂、可常温操作等优点,实现了膜分离技术与乳制品加工技术的有效结合,在乳制品加工行业中越来越受关注。本文以膜的渗透通量及截留率作为最主要研究参数。采用脱脂牛奶作为原料,考察压力、膜面流速等条件对陶瓷超滤膜分离乳糖的影响,分析浓缩倍数对乳糖截留率及分离稳定性的影响。主要研究内容如下:

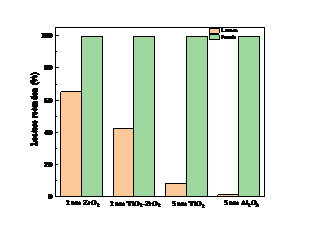

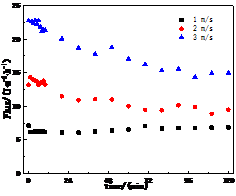

首先针对牛奶中乳糖的分离,初步选择了4种陶瓷超滤膜,分别为平均孔径为2 nm的ZrO2和TiO2-ZrO2超滤膜,以及平均孔径为5 nm的Al2O3和TiO2超滤膜。分别采用这4种陶瓷膜对牛奶中的乳糖进行脱除,对操作压力,膜面流速等分离工艺参数进行考察与优化。经过实验研究,本文选取平均孔径为5 nm的Al2O3超滤膜较适合于牛奶中乳糖的脱除,增大跨膜压差和膜面流速可以提高膜的渗透通量,增大跨膜压差会增大乳糖的截留率,增大膜面流速会降低乳糖的截留率,综合考虑,陶瓷超滤膜分离牛奶中乳糖的最优分离工艺参数是:压力为0.2 MPa,膜面流速为3 m/s,温度为23 °C。

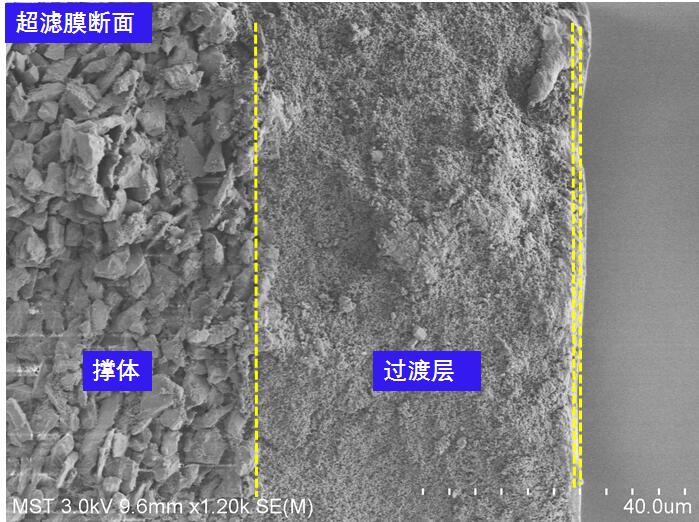

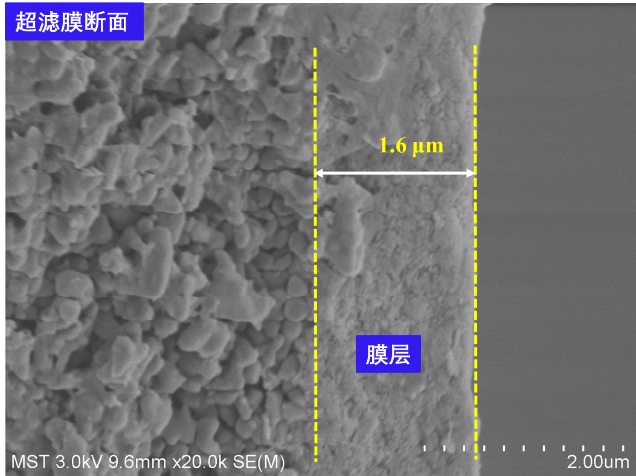

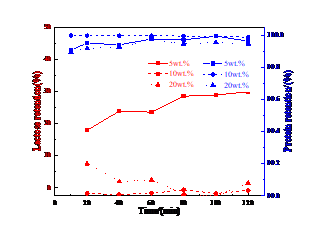

选用的5 nm Al2O3陶瓷纳滤膜表面平整无缺陷,过渡层和膜层紧密结合,膜层厚度为1.6 µm;膜的纯水渗透率为75.5 L∙m-2∙h-1;膜的截留分子量为21 kDa,平均孔径为5.7 nm。在优化的工艺参数下,平均孔径为5 nm的Al2O3陶瓷纳滤膜对蛋白的截留率几乎达到100%,而对乳糖的截留率仅为1%,可以有效实现牛奶中乳糖的有效脱除,在连续运行12h后平均孔径为5 nm的Al2O3陶瓷纳滤膜的通量维持在较高水平,约为7.5 L·m-2·h-1。陶瓷超滤膜在制备低乳糖牛奶中展现了良好的应用前景。

关键词:陶瓷膜 超滤 乳糖

Remove Lactose From Milk by Ceramic Membrane Separation Technology

Abstract

In recent years, with the continuous increase of national economic income, organic milk and low-fat milk have become the hot selling products in the market. Conventional low-lactose milk production involves the addition of lactase to the milk to break down the sugar content. In the processing of dairy products, membrane separation technology has the advantages of low environmental pollution, low energy consumption, no need to use additives, normal temperature operation, etc., realizing the effective combination of membrane separation technology and dairy products processing technology, more and more attention in the dairy products processing industry. In this paper, the permeation flux and interception rate of the membrane are taken as the main research parameters. Skim milk was used as raw material to study the effects of pressure and membrane velocity on the separation of lactose in ceramic ultrafiltration membrane. The main research contents are as follows:

Firstly, four kinds of ceramic ultrafiltration membranes were preliminarily selected for the separation of lactose in milk, namely ZrO2 and TiO2-ZrO2 ultrafiltration membranes with an average pore diameter of 2 nm, and Al2O3 and TiO2 ultrafiltration membranes with an average pore diameter of 5 nm. The four ceramic membranes were used to remove lactose from milk, and the separation process parameters, such as operating pressure and membrane flow rate, were investigated and optimized. Through experimental research, this article selects the average pore diameter of 5 nm of Al2O3 ultrafiltration membrane is suitable for the removal of lactose in milk, increasing the pressure difference can improve the permeability of membrane flux and membrane surface flow velocity, pressure difference will increase the entrapment rate of lactose, increase the flow velocity at the membrane surface will decrease the rate of interception of lactose, comprehensive consideration, ceramic ultrafiltration membrane separation of lactose in milk the optimal separation process parameters are: pressure is 0.2 MPa, the membrane surface velocity of 3 m/s, temperature of 23 ° C.

The selected 5 nm Al2O3 ceramic ultrafiltration membrane has a flat surface and no defects. The transition layer is closely combined with the membrane layer, and the thickness of the membrane layer is 1.6µm. The pure water permeability of the membrane was 75.5 L∙m-2∙h-1. The retained molecular weight of the membrane was 21 kDa and the average pore diameter was 5.7 nm. Under the optimized process parameters, the average aperture of 5 nm of Al2O3 ceramic ultrafiltration membrane intercept rate is almost 100% of protein, and withholding rate is only 1% of lactose, can effectively achieve the effective removal of lactose in the milk, after 12 h of continuous running average aperture of 5 nm Al2O3 ceramic ultrafiltration membrane flux maintained at a higher level, about 7.5 L∙m-2∙h-1.Ceramic ultrafiltration membrane showed good application prospect in the preparation of low lactose milk.

Key words: Ceramic membrane; Ultrafiltration; Lactose

目录

摘要 I

Abstract II

目录 IV

第一章 文献综述 1

1.1低乳糖乳制品研究概述 1

1.1.1乳糖不耐受概述 1

1.1.2国内外低乳糖乳制品市场发展前景 1

1.2低乳糖牛奶技术研究概述 2

1.2.1酸水解法制备低乳糖牛奶 2

1.2.2酶水解法制备低乳糖牛奶 2

1.2.3基因工程技术制备低乳糖牛奶 3

1.2.4膜分离法制备低乳糖牛奶 3

1.3膜技术在乳品工业中的应用 3

1.3.1原料乳的除菌 3

1.3.2乳制品废水处理 3

1.3.3乳清脱盐 3

1.3.4牛奶浓缩 3

1.3.5干酪生产中的应用 4

1.4研究的目的和意义 4

第二章 陶瓷超滤膜分离牛奶中乳糖的研究 5

2.1引言 5

2.2实验部分 5

2.2.1 实验材料及仪器 5

2.2.2陶瓷超滤膜的表征 6

2.2.3陶瓷超滤膜分离牛奶中乳糖实验 7

2.3 结果与讨论 8

2.3.1陶瓷超滤膜的选择与表征 8

2.3.2陶瓷超滤膜分离牛奶中乳糖 12

第三章 结论与展望 19

3.1结论 19

3.2展望 19

参考文献 21

致谢 23

第一章 文献综述

1.1低乳糖乳制品研究概述

随着国民经济收入的不断增长,有机奶、低脂奶成为了市场的热销产品。乳品消费总量以6.83%[1]的年增长率增长,其中主要增长的是:奶粉、奶酪、冰淇淋和发酵乳等。然而在我国,高达75%[2]以上的人群存在乳糖不耐受,低乳糖乳制品需求量巨大。

1.1.1乳糖不耐受概述

乳糖不耐受是因为人体内不产生乳糖酶或者乳糖酶活性低而阻碍乳糖被分解、吸收,从而引起腹泻、腹胀等症状[3]。因为牛奶中的乳糖进入人体后不能直接被吸收,需要通过乳糖酶水解,生成葡萄糖和半乳糖后才能被人体吸收[4]。乳糖酶是人体内一种专业分解乳糖的酶类,假如没有乳糖酶,或乳糖酶含量太少,那么乳糖会被微生物发酵成大量的有机酸和二氧化碳等气体,引起腹胀、腹痛、腹泻[5]。

乳糖不耐受发生几率普遍存在于全世界[5],不同国家存在乳糖不耐受的人群比例不同,欧洲人群比例为约为30%;非洲人群比例约为90%;亚洲人群的比例为70%[6]。我国的乳糖不耐受人群比例高达75%[2],南北方的比例还不同,呈现出地域不同。中国乳制品工业发展疾速,但与世界的乳制品工业生产水平有着显著的差距,庞大的乳糖不耐受人群基数和乳制品种类的不匹配,严重阻碍了乳制品工业的发展。

1.1.2国内外低乳糖乳制品市场发展前景

解决乳糖不耐受的最好解决方法是开发低乳糖或无乳糖乳制品。传统的发酵乳制品虽能成为乳糖不耐受人群的替代选择品,但因水解率低和营养成分丢失,营养价值无法与牛奶相比[7]。因此,乳制品企业开发低乳糖牛奶、扩大市场份额有着很好的市场前景[8]。

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。