陶瓷膜接触器用于处理高氨氮废水的研究毕业论文

2020-04-20 13:52:43

摘 要

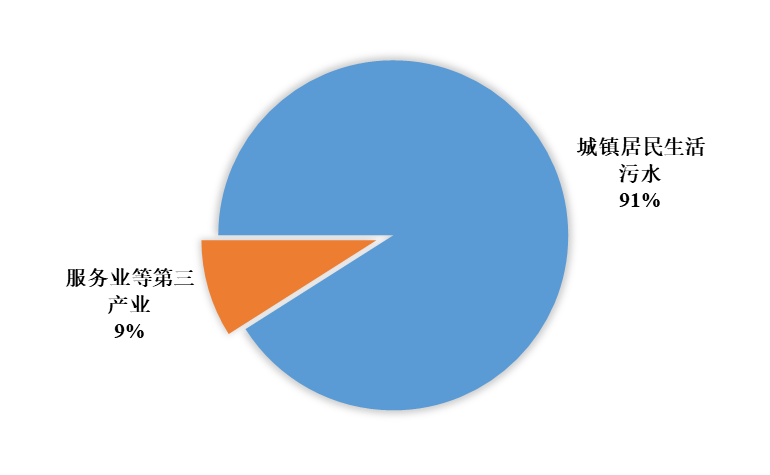

氨氮废水指含有一定量游离氨(NH3)和铵根离子(NH4 )的废水,当氨氮含量大于500mg/L时称为高浓度氨氮废水即高氨氮废水。随着国民经济的发展与社会的进步,国家对于氨氮排放的要求愈加严苛,目前我国的氨氮排放量虽然同比往年有明显下降,但整体仍处于高位水平,且具有多种不同来源的氨氮废水,给氨氮废水的处理带来极大困难。氨氮废水会造成许多危害,如威胁人畜的生命健康安全,导致经济财产损失,造成水体富营养化、引发赤潮等。在讲求“绿水青山就是金山银山”的今天,各行业均需要对氨氮废水进行合理、有效的末端治理。

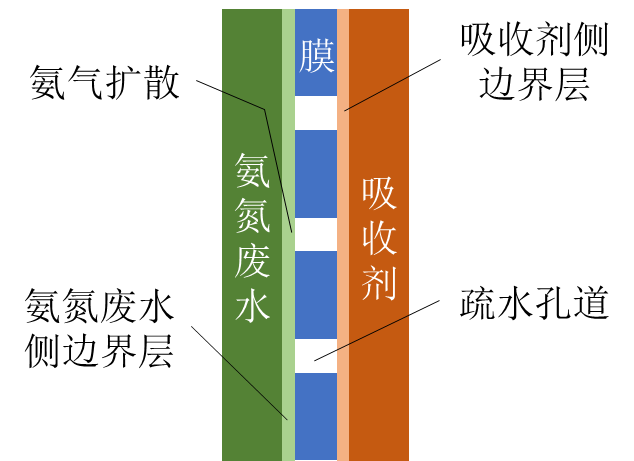

现有的氨氮废水处理技术主要有蒸汽吹脱法、化学沉淀法、生物处理法、吸附分离法、折点氯化法、膜分离法等。传统氨氮脱除工艺如蒸汽吹脱法存在能耗高、占地面积大、处理效率低等缺点;膜接触器法(又称为直接接触式膜蒸馏)是膜分离方法中的一种新型技术,具有能耗较低、占地面积小、分离效率高、分离效果稳定等优点。膜材料对膜接触器处理氨氮废水的效果存在较大的影响,目前见报道的用作膜接触器的膜以聚丙烯(PP)中空纤维膜、聚偏氟乙烯(PVDF)中空纤维膜、聚四氟乙烯(PTFE)中空纤维膜为主,本项目依托南京工业大学化工学院、膜科学技术研究所的相关研究结果,结合课题组自身优势,选用使用改性疏水陶瓷膜作为膜接触器。

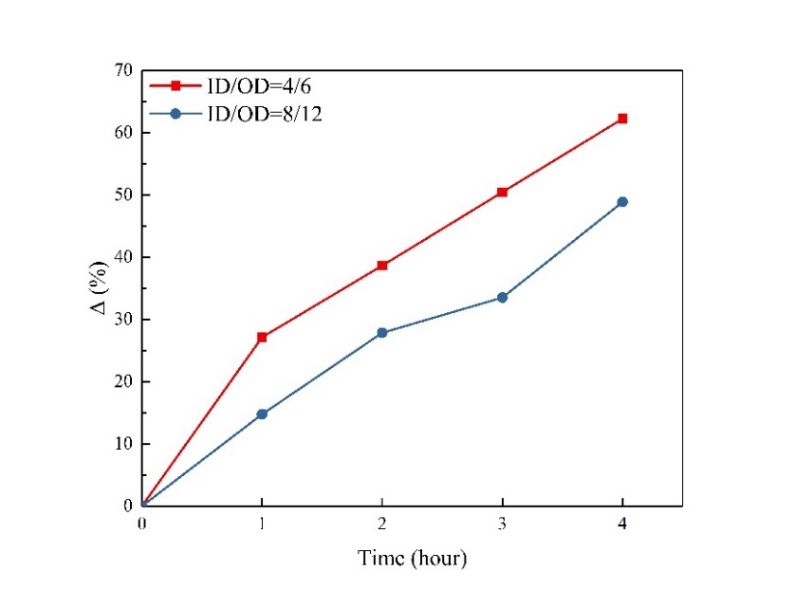

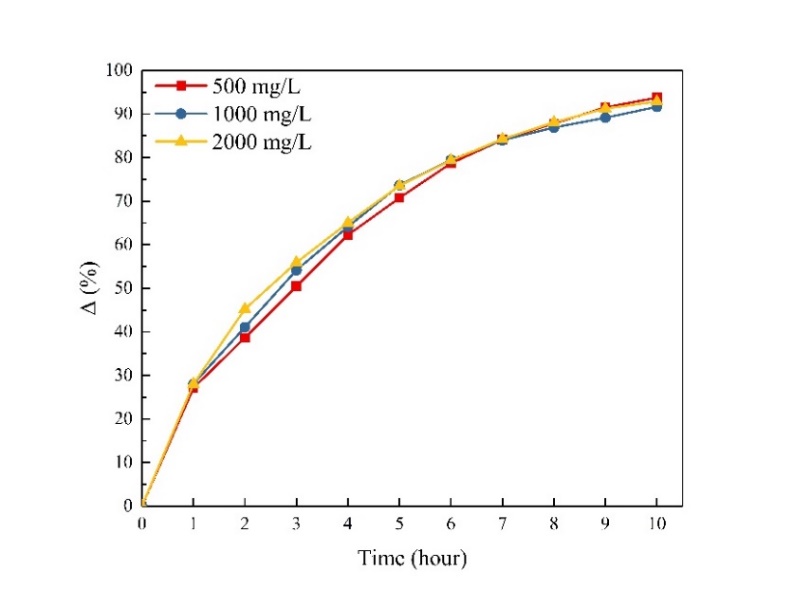

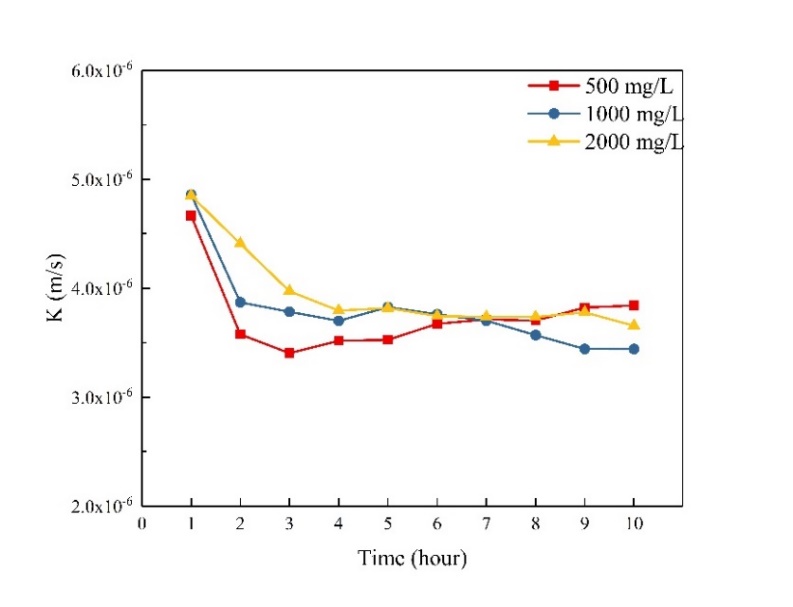

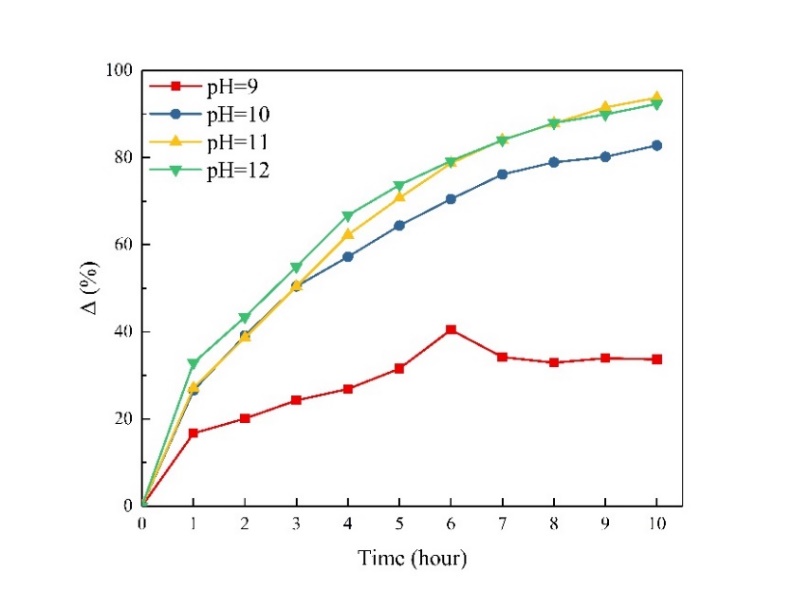

本课题考察了陶瓷膜接触器用于处理高氨氮废水的可行性研究,发现该方法适用于不同氨氮浓度高氨氮废水;考察了氨氮废水初始浓度、氨氮废水初始pH、氨氮废水温度、吸收剂浓度、氨氮废水流速等因素对于去除效果的影响。在最佳操作条件下,使用内径为4mm、外径为6mm的陶瓷膜管作为膜接触器对浓度为500mg/L模拟氨氮废水进行氨氮脱除实验(氨氮废水体积150mL,吸收剂体积150mL),10小时氨氮脱除率可以达到95%以上。对实验结果通过氨氮脱除率、传质系数的计算与比较,发现壁厚较薄的膜管、在一定限度内提高氨氮废水的初始pH、提高氨氮废水的处理温度、提高氨氮废水的流速等都能有效提高氨氮脱除率及陶瓷膜接触器的传质系数。

关键词:陶瓷膜 氨氮废水 膜接触器 直接接触式膜蒸馏

Study on the application of ceramic membrane contactor in the treatment of high ammonia nitrogen wastewater

Abstract

Ammonia nitrogen wastewater refers to wastewater containing a certain amount of free ammonia (NH3) and ammonium ion (NH4 ). When the ammonia nitrogen content is greater than 500 mg/L, it is called high concentration ammonia nitrogen wastewater. With the development of the national economy and the progress of the society, the country's requirements for ammonia nitrogen emission are becoming more and more stringent. At present, although the ammonia nitrogen emission in China has decreased significantly from the previous year, the overall level is still at a high level, and there are many different sources of ammonia nitrogen wastewater. It brings great difficulty to the treatment of ammonia nitrogen wastewater. Ammonia-nitrogen wastewater can cause many hazards, such as threatening the health and safety of human and animal life, resulting in loss of economic property, resulting in eutrophication of water bodies and red tides. Today, we emphasize the need for rational and effective end-treatment of ammonia-nitrogen wastewater.

The existing ammonia nitrogen wastewater treatment technologies mainly include steam stripping method, chemical precipitation method, biological treatment method, adsorption separation method, break point chlorination method, membrane separation method and the like. Traditional ammonia nitrogen removal processes such as steam stripping have disadvantages such as high energy consumption, large floor space, and low processing efficiency; membrane contactor method (also known as direct contact membrane distillation) is a new technology in membrane separation methods. The utility model has the advantages of low energy consumption, small floor space, high separation efficiency and stable separation effect. The membrane material has a great influence on the effect of the membrane contactor on the treatment of ammonia-nitrogen wastewater. Currently, the membranes used as membrane contactors are reported as polypropylene (PP) hollow fiber membranes, polyvinylidene fluoride (PVDF) hollow fiber membranes, and poly-polymers. Tetrafluoroethylene (PTFE) hollow fiber membrane is the main method. This project relies on the relevant research results of the College of Chemical Engineering and the Institute of Membrane Science and Technology of Nanjing Tech University, and combines the advantages of the research group to select the modified hydrophobic ceramic membrane as the membrane contactor.

In this paper, the feasibility study of ceramic membrane contactor for treating high ammonia nitrogen wastewater was investigated. It was found that the method was suitable for high ammonia nitrogen wastewater with different ammonia nitrogen concentration. The initial concentration of ammonia nitrogen wastewater, the initial pH of ammonia nitrogen wastewater, the ammonia nitrogen wastewater temperature, the concentration of absorbent, The influence of factors such as ammonia nitrogen wastewater flow rate on the removal effect. Under the optimal operating conditions, a ceramic membrane tube with an inner diameter of 4 mm and an outer diameter of 6 mm was used as a membrane contactor for ammonia nitrogen removal experiments with a concentration of 500 mg/L simulated ammonia nitrogen wastewater (ammonia nitrogen wastewater volume 150 mL, absorbent volume 150 mL). The 10-hour ammonia nitrogen removal rate can reach more than 95%. Through the calculation and comparison of ammonia nitrogen removal rate and mass transfer coefficient, it is found that the membrane tube with thin wall thickness increases the initial pH of ammonia nitrogen wastewater within a certain limit, increases the treatment temperature of ammonia nitrogen wastewater, and increases the flow rate of ammonia nitrogen wastewater. Both can effectively improve the ammonia nitrogen removal rate and the mass transfer coefficient of the ceramic membrane contactor.

Key Words: Ceramic membrane; Ammonia nitrogen wastewater; Membrane contactor; Direct contact membrane distillation.

目录

摘 要 I

Abstract III

目录 i

第一章 文献综述 1

1.1氨氮废水概述 1

1.1.1氨氮废水含义 1

1.1.2氨氮废水来源 1

1.1.3氨氮废水的危害 3

1.2氨氮废水处理方法 4

1.3膜接触器处理氨氮废水 6

1.3.1膜分离概述 6

1.3.2膜接触器处理氨氮废水研究进展 6

1.3.3膜接触器的选择 6

1.4课题研究的意义 7

第二章 实验 8

2.1试剂与仪器 8

2.1.1试剂 8

2.1.2仪器 8

2.1.3膜组件参数 8

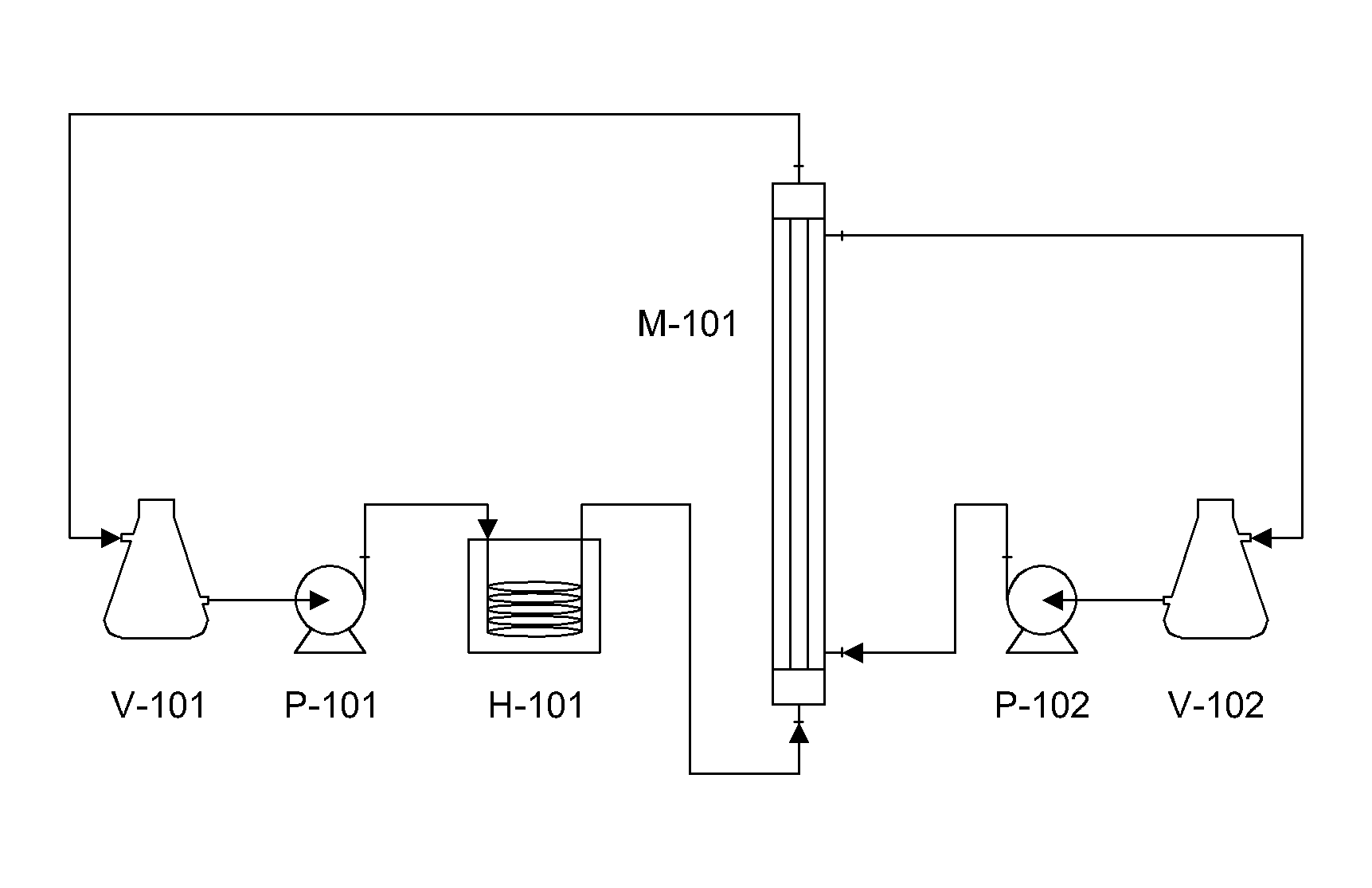

2.2装置与流程 9

2.2.1实验原理 9

2.2.2实验装置 10

2.2.3实验流程 11

2.2.4结果检测 11

2.3数据分析 12

2.3.1氨氮脱除率 12

2.3.2传质系数 12

第三章 结果与分析 13

3.1膜管的选择 13

3.2操作条件考察 15

3.2.1模拟氨氮废水初始浓度 15

3.2.2模拟氨氮废水初始pH 16

3.2.3模拟氨氮废水温度 18

3.2.4吸收剂浓度 19

3.2.5模拟氨氮废水流速 21

第四章 结论与展望 24

4.1结论 24

4.2展望 24

参考文献 26

致谢 28

- 文献综述

1.1氨氮废水概述

1.1.1氨氮废水含义

以上是毕业论文大纲或资料介绍,该课题完整毕业论文、开题报告、任务书、程序设计、图纸设计等资料请添加微信获取,微信号:bysjorg。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。