DD3R型分子筛膜的制备与氢气分离性能研究毕业论文

2020-04-22 19:44:23

摘 要

随着全球能源需求增长,发展可持续清洁能源成为最首要的任务。氢气是最有潜力的清洁燃料之一,具有高能效、零碳排放,以及在燃烧时仅产生水的特点。工业上H2产品往往是由H2和其他气体所组成的混合物。因此,为满足H2的应用要求,分离过程必不可少。膜分离是一项重要的分离技术,在众多膜材料中,DD3R分子筛膜拥有独特的孔道结构与全硅的骨架结构,使得该类膜材料在分离过程中显示出良好的稳定性。此外,DD3R分子筛膜的有效孔径为0.36 nm×0.44 nm,可用于从较大气体分子中分离H2,这使它成为一种潜力巨大的透氢膜材料。本文采用球磨Sigma-1作为晶种进行诱导合成DD3R分子筛膜,采用低温臭氧煅烧法进行活化,并探究DD3R分子筛膜的H2分离性能。

首先,本文进行DD3R分子筛膜的合成与活化。将四通道氧化铝中空纤维进行预处理;进行晶种液的配制与涂覆;在不锈钢反应釜中进行水热合成,得到DD3R分子筛膜。为脱除模板剂,本文采用低温臭氧煅烧法进行DD3R分子筛膜的活化。

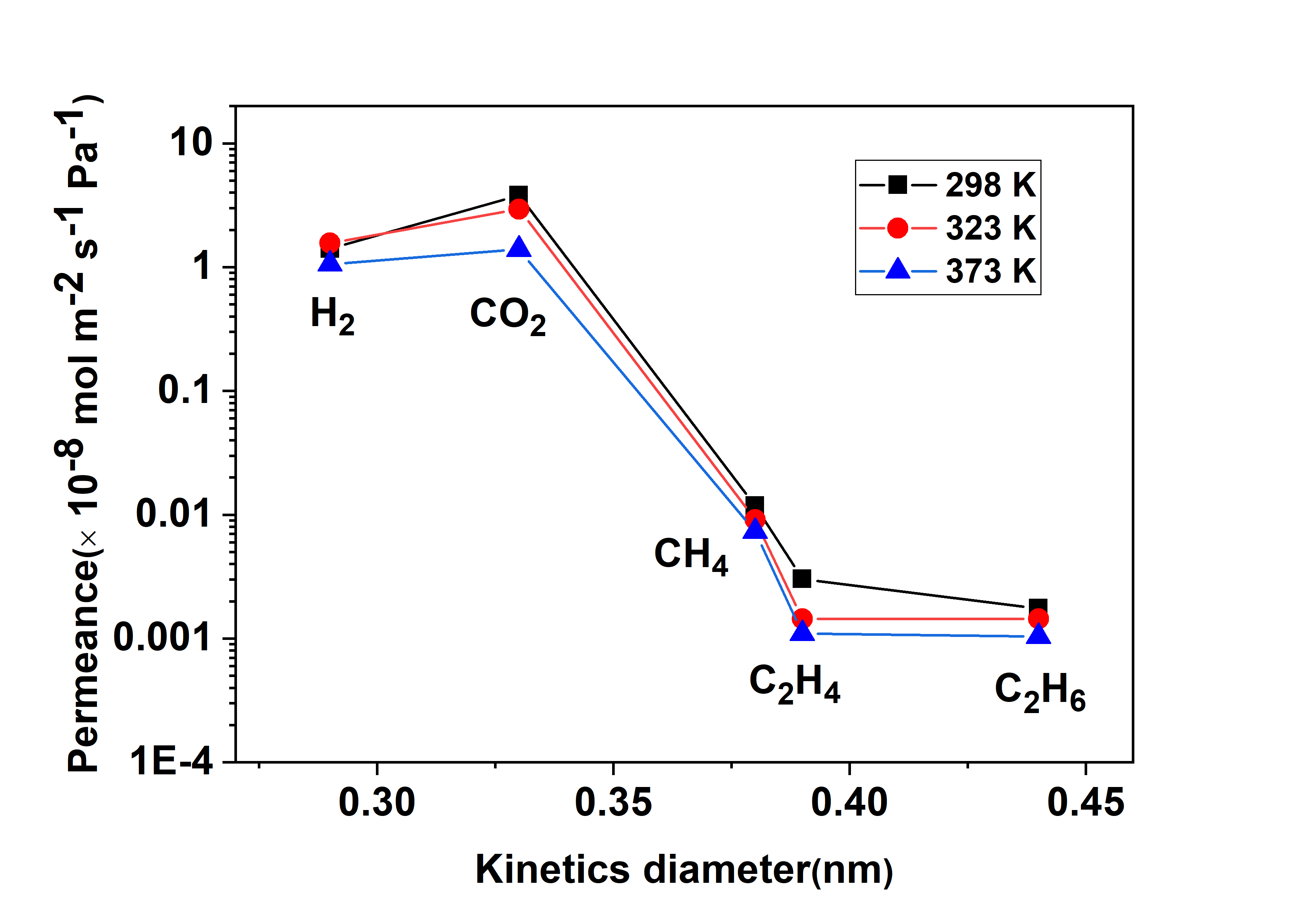

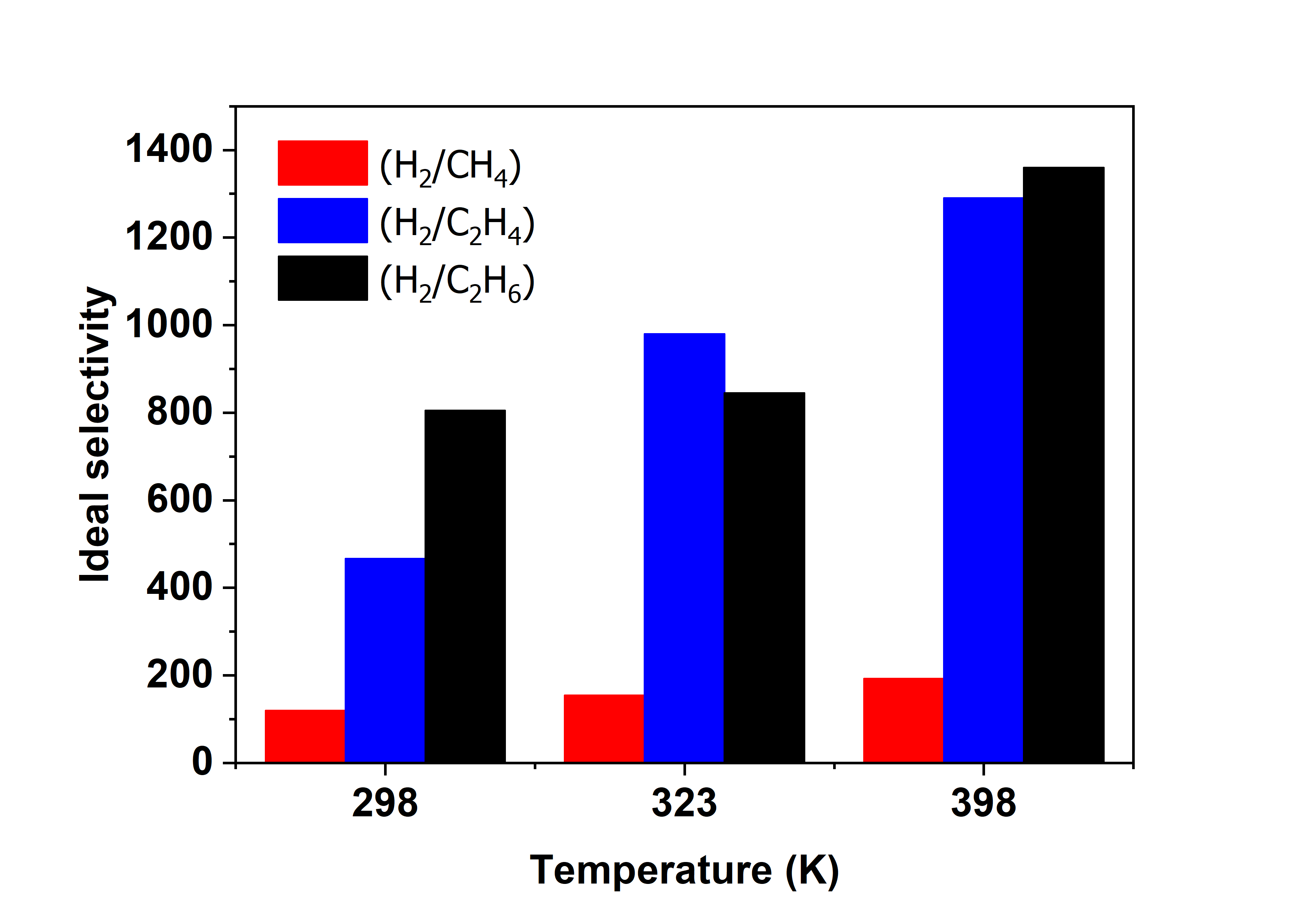

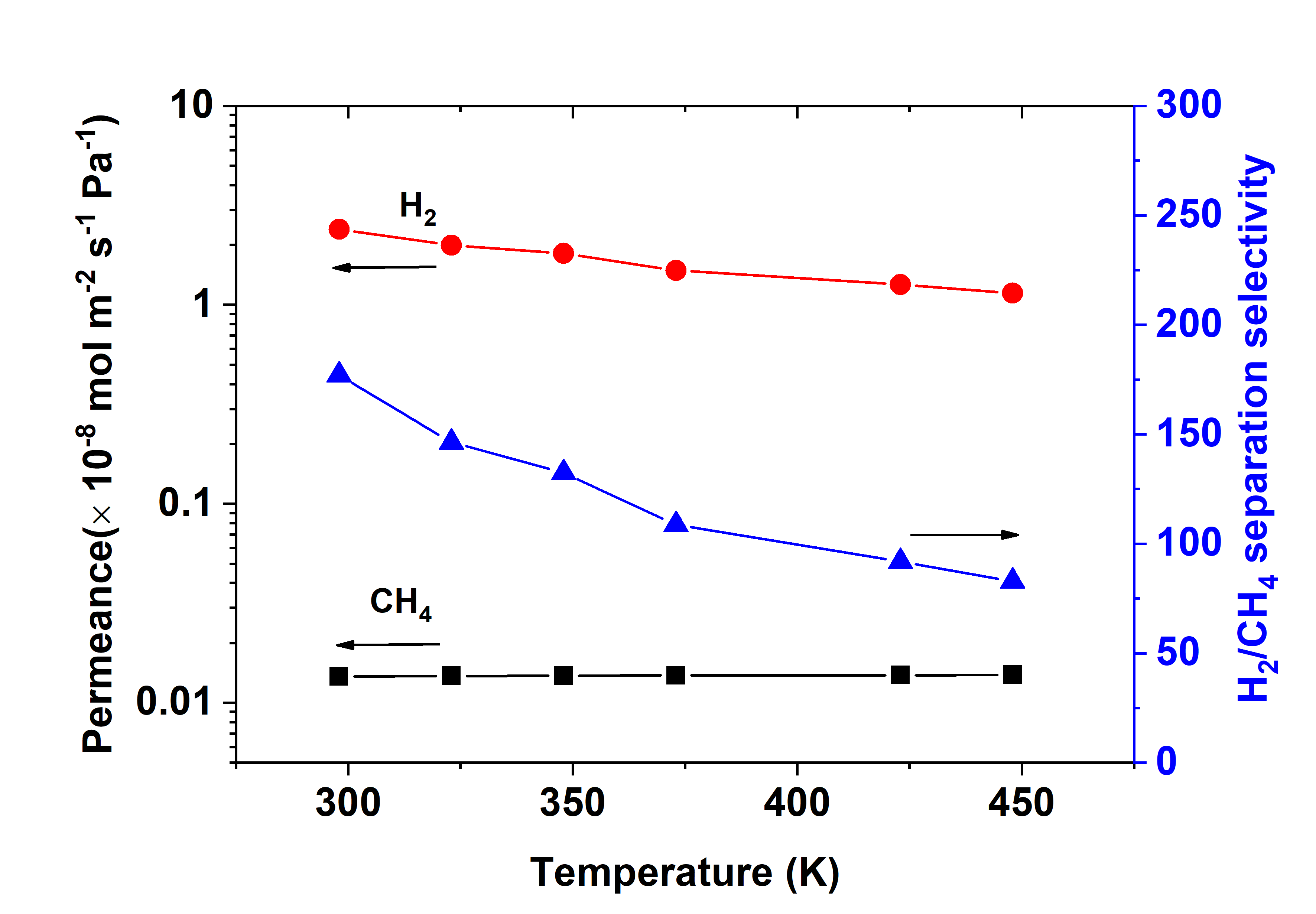

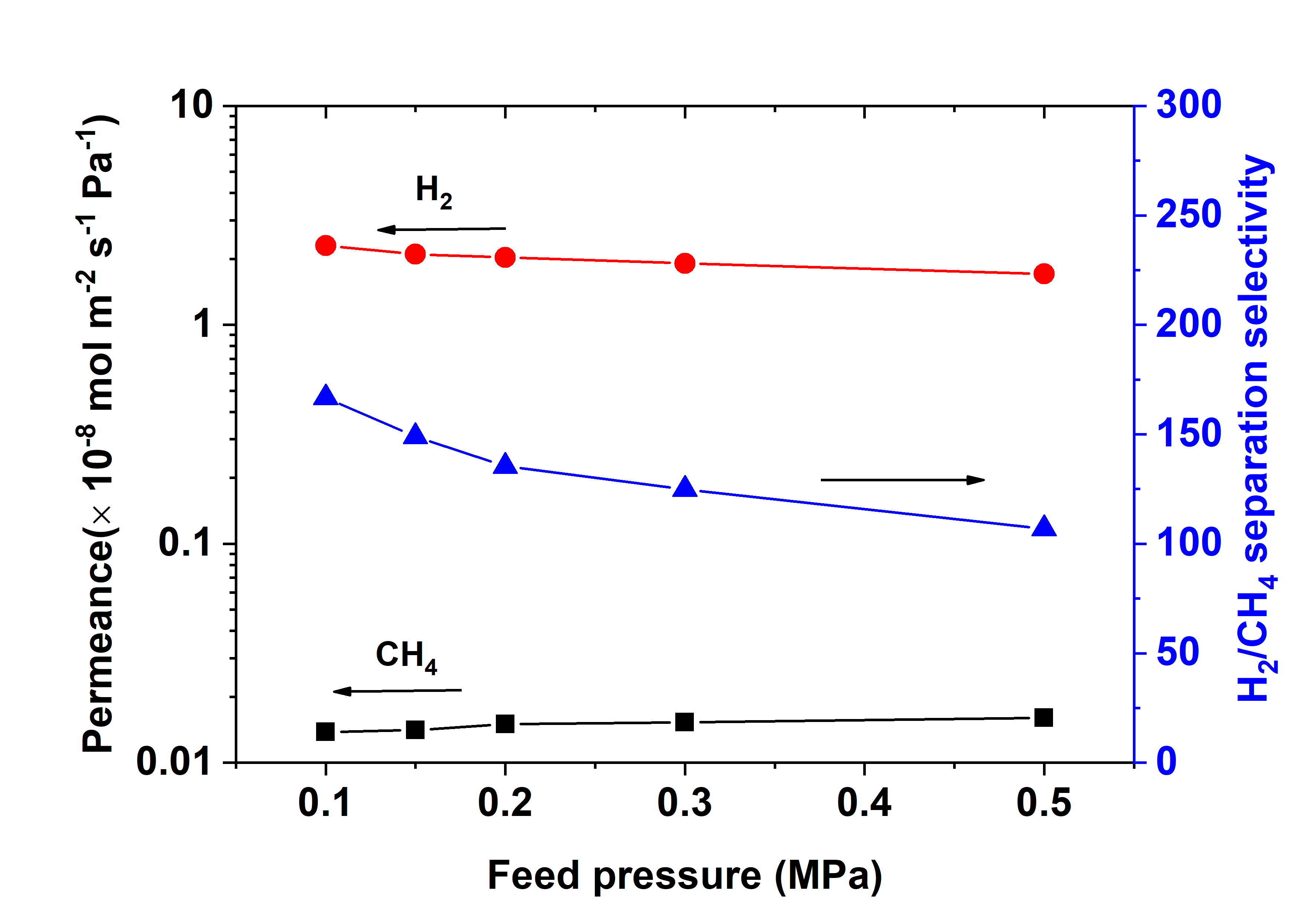

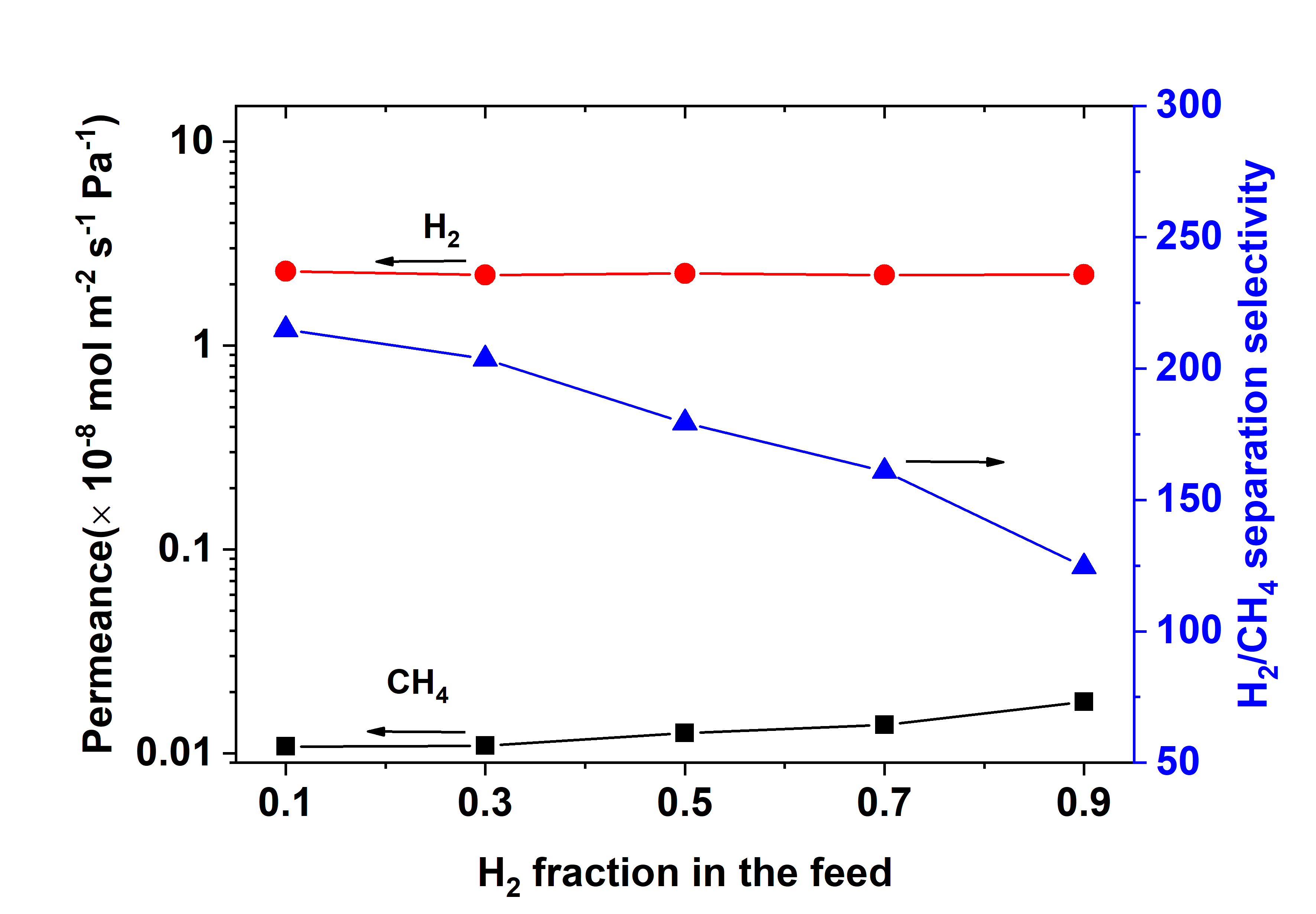

随后,本文对DD3R分子筛膜进行了H2/CH4分离性能研究。将DD3R分子筛膜进行单组份气体表征,得到渗透性大小排序为:CO2 gt; H2 gt; CH4 gt; C2H4 gt; C2H6。本文系统考察了温度、压力及H2分率对活化后的DD3R分子筛膜分离性能的影响。低温臭氧煅烧法活化的DD3R分子筛膜H2/CH4气体的分离性能良好,在298 K,进料压力为0.1 MPa(吹扫气体为He,流量为100 ml·min-1),进料中H2分率为0.1时,分离选择性可达214。

最后,本文将杂质气体引入H2/CH4体系,并进行分离性能的研究。将C2H6作为杂质气体引入,导致H2/CH4分离选择性的下降,但随着温度升高,H2/CH4分离选择性逐渐回升。当体系当进料摩尔比为H2: CH4: C2H6=50: 50: 10,温度为298 K时,H2/CH4分离选择性能保持在138左右,移除杂质气体之后,分离选择性重新回到162左右,说明该膜稳定性良好,体现出较好的H2/CH4分离性能。在C2H4气体作为杂质时验证稳定性,可以得到相同的结论。本研究丰富了DD3R分子筛膜的气体分离数据,为后续拓展研究奠定了基础。

关键词:DD3R分子筛膜 H2分离 渗透性 中空纤维

ABSTRACT

It is important to develop sustainable and clean forms of energy to satisfy energy demand of global. Hydrogen is one of the most promising energy sources due to its high energetic efficiency, zero carbon emission and yielding only water. The industrial H2 product often contains H2 and some other gases, such as CH4, C2H6 and C2H4. Therefore, to satisfy requirements of applications, downstream separation processes are necessary. Membrane technology is an efficient and energy saving way of separating. Among many membrane materials, DD3R zeolite membrane has a unique pore structure and an all-silica structure, which makes the membrane material exhibit strong stability during the separation process. DD3R is a particularly promising membrane material for hydrogen separation from larger gas molecules due to its 8-membered ring pore aperture of 0.36 nm×0.44 nm. In this work, high-quality DD3R zeolite membranes were synthesized on the hollow fiber by using ball-milled Sigma-1 seeds. DD3R zeolite membranes were activated by low-temperature activation at ozone atmosphere, and to study the H2 separation performance.

Firstly, the DD3R zeolite membranes were prepared on the α-Al2O3 support using ball-milled Sigama-1 as seeds. The α-Al2O3 four-channel hollow fiber supports were pretreated; then, an aqueous seeds suspension was prepared and coated; hydrothermal synthesis was carried out in a stainless steel reactor to obtain DD3R zeolite membrane. and it was activated by low-temperature activation at ozone atmosphere.

Secondly, the hollow fiber DD3R zeolite membranes were investigated on H2/CH4 separation. The DD3R zeolite membrane was characterized by single gas. The permeability followed an order as: CO2 gt; H2 gt; CH4 gt; C2H4 gt; C2H6. In this thesis, effects of temperature, feed pressure and H2 fraction in the feed on separation performance of DD3R zeolite membranes were investigated. DD3R zeolite membrane activated with ozone at low temperature had a good separation selectivity for H2/CH4. At 298 K, the separation selectivity was achieved to 214 when the H2 fraction in the feed was 0.1 and the feed pressure was 0.1 MPa.

Finally, the effect of impurity on separation characteristics of DD3R zeolite membrane for H2/CH4 were investigated. Then, C2H6 was introduced as an impurity gas into the H2/CH4 system, which led to a decrease in the separation selectivity for H2/CH4, but as the temperature increased, the H2/CH4 separation selectivity increased. When the feed molar ratio was H2: CH4: C2H6=50: 50: 10 and the temperature was 298 K, the H2/CH4 separation selectivity maintained at around 138. After the impurity gas was removed, the separation selectivity recovered to 162, indicating that the membrane was stable and exhibited good separation performance. The same conclusions could be obtained when C2H4 was introduced as an impurity gas into the H2/CH4 system. This study enriched the gas separation data of DD3R zeolite membrane and laid the foundation for future research.

Keywords: DD3R zeolite membranes; H2 separation; permeance; hollow fiber

目 录

摘要 I

ABSTRACT i

目 录 1

第一章 文献综述 1

1.1 引言 1

1.2 氢气能源现状及其分离技术 1

1.2.1 氢气能源现状 1

1.2.2 氢气分离技术 3

1.3 分子筛膜法分离氢气 4

1.3.1 分子筛膜简介 4

1.3.2 分子筛膜的合成方法 4

1.3.3 分子筛膜在氢气分离中的研究进展 6

1.4 DD3R分子筛膜研究现状 6

1.4.1 DD3R分子筛膜简介 6

1.4.2 DD3R分子筛膜研究进展 7

1.4.3 DD3R分子筛膜的合成与活化 8

1.5 本文研究意义及内容 8

第二章 DD3R分子筛膜的合成与活化及H2/CH4分离性能研究 10

2.1 引言 10

2.2 实验部分 10

2.2.1 实验试剂及仪器 10

2.2.2 中空纤维DD3R分子筛膜的合成与活化 11

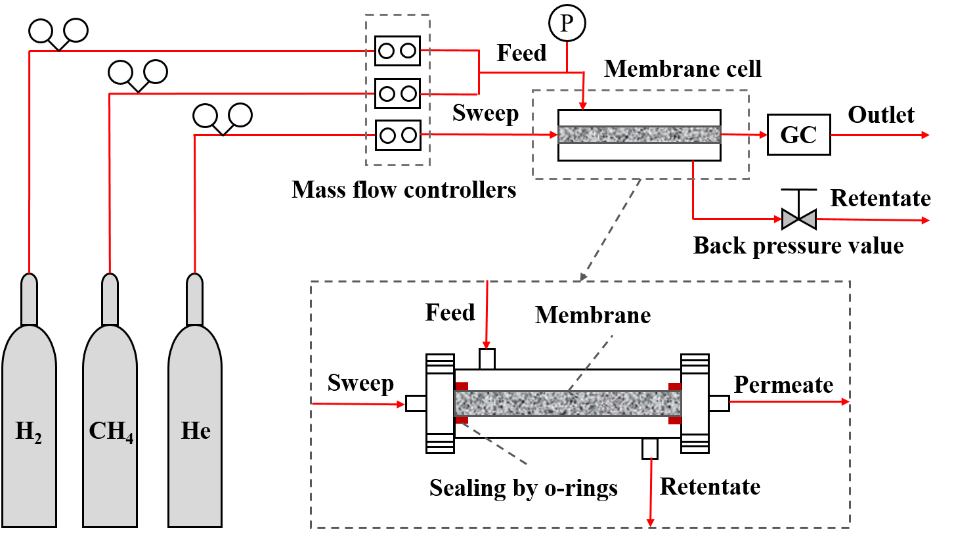

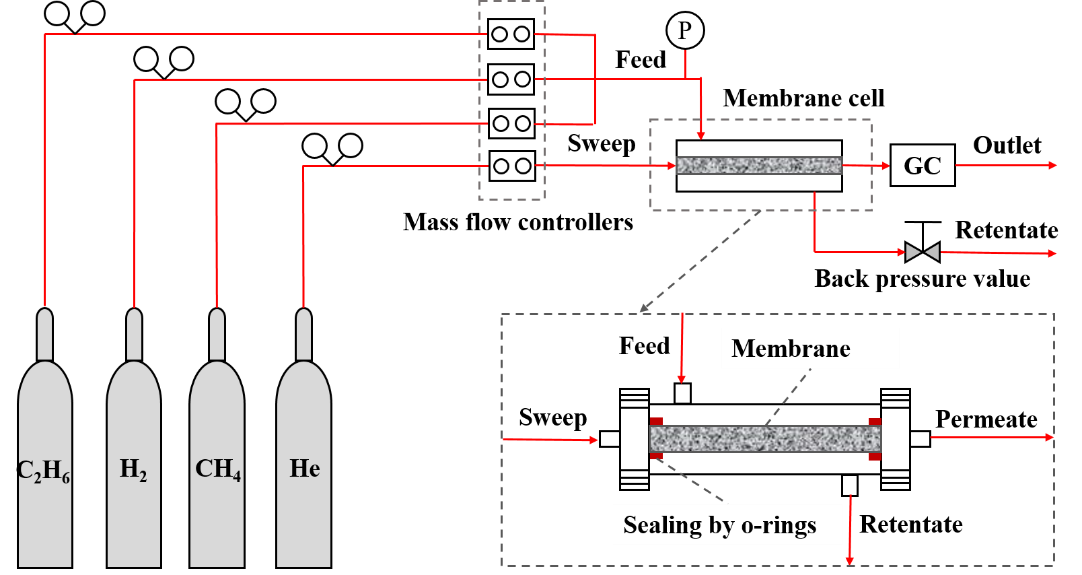

2.2.3 中空纤维DD3R分子筛膜的单组份气体渗透表征 13

2.2.4 中空纤维DD3R分子筛膜的H2/CH4分离表征 13

2.3 结果与讨论 14

2.3.1 中空纤维DD3R分子筛膜的单组份气体渗透性能 14

2.3.2 中空纤维DD3R分子筛膜的H2/CH4体系分离性能 15

2.4 本章小结 18

第三章 杂质气体引入对DD3R分子筛膜气体分离性能影响的研究 20

3.1 引言 20

3.2 实验部分 20

3.2.1 实验试剂及仪器 20

3.2.2 中空纤维DD3R分子筛膜的气体分离性能表征 21

3.3 结果与讨论 21

3.3.1 中空纤维DD3R分子筛膜的H2/CH4/C2H6体系分离性能 21

3.3.2 中空纤维DD3R分子筛膜的H2/CH4/C2H4体系分离性能 24

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。