低阻力高温气体过滤材料的制备毕业论文

2020-04-26 12:58:32

摘 要

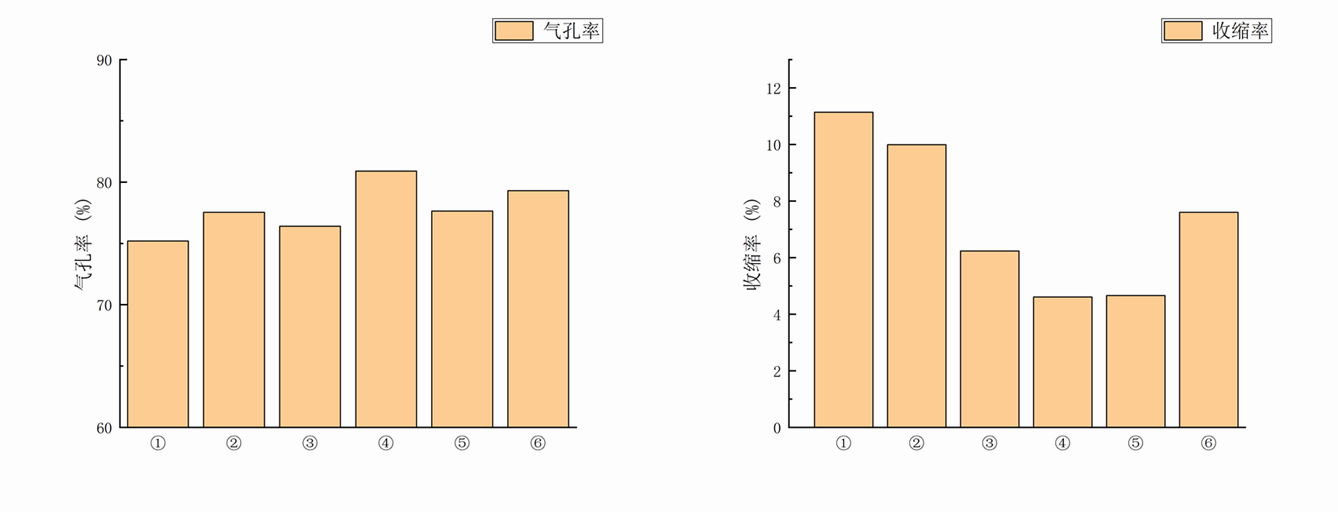

目前,国内环保政策日益严格,大气污染的管控已成为社会的一大热点,颗粒物是污染大气的首要“元凶”。在这种背景下,高耗能、高排放企业要想达到“超低排放”标准,必须着眼于高温气体过滤材料和设备的研究和高效使用。在烟气直接过滤领域,多孔陶瓷材料一直是科学界和企业关注的重点,过滤效率高,设备投资少,可避免二次污染,都是这种材料的优点。传统的多孔陶瓷材料普遍存在强度不高、抗热震性差等缺点。用陶瓷纤维作为材料基体,加入无机粘结剂,制作纤维基陶瓷过滤材料,耐酸碱腐蚀,强度高,抗热震性好。

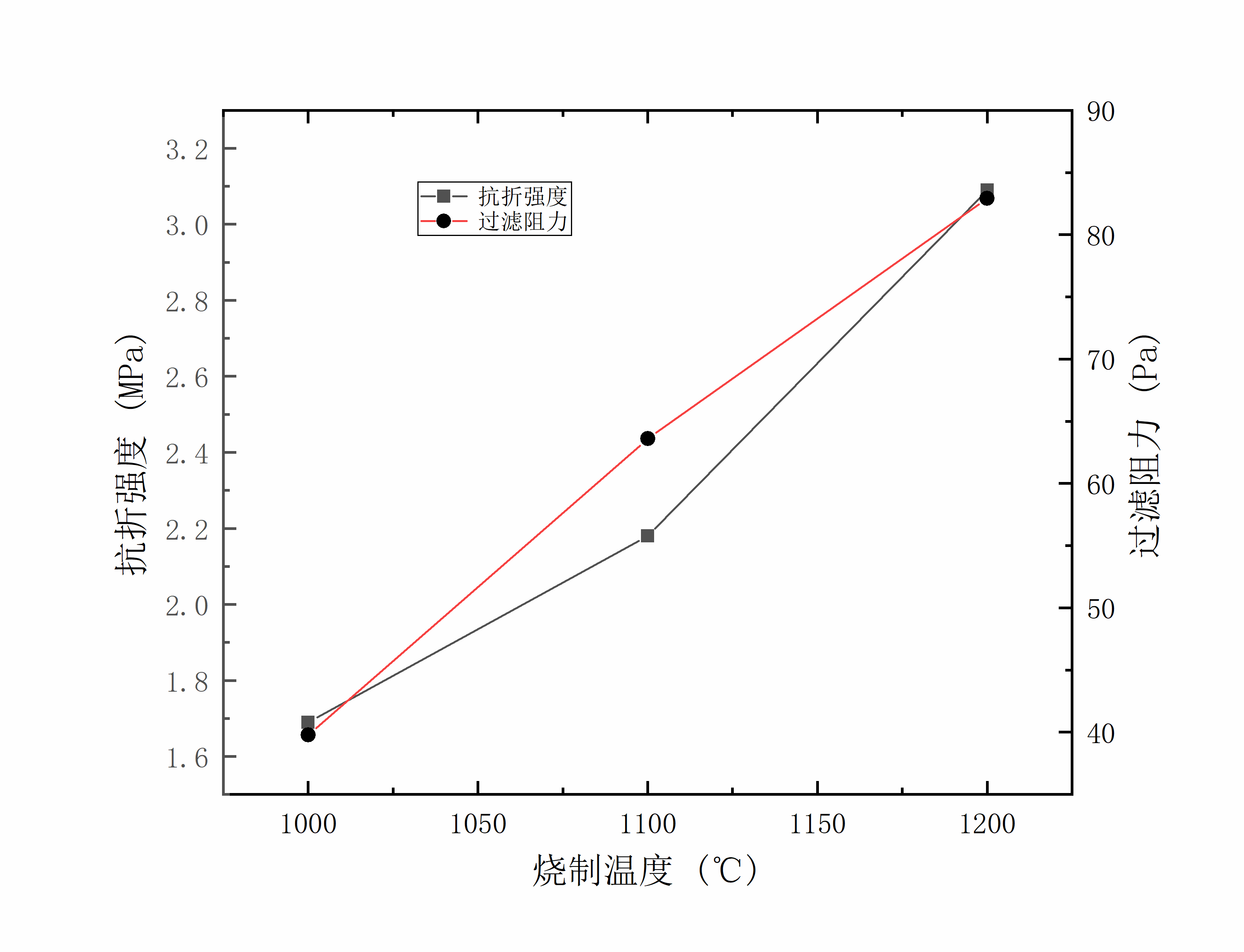

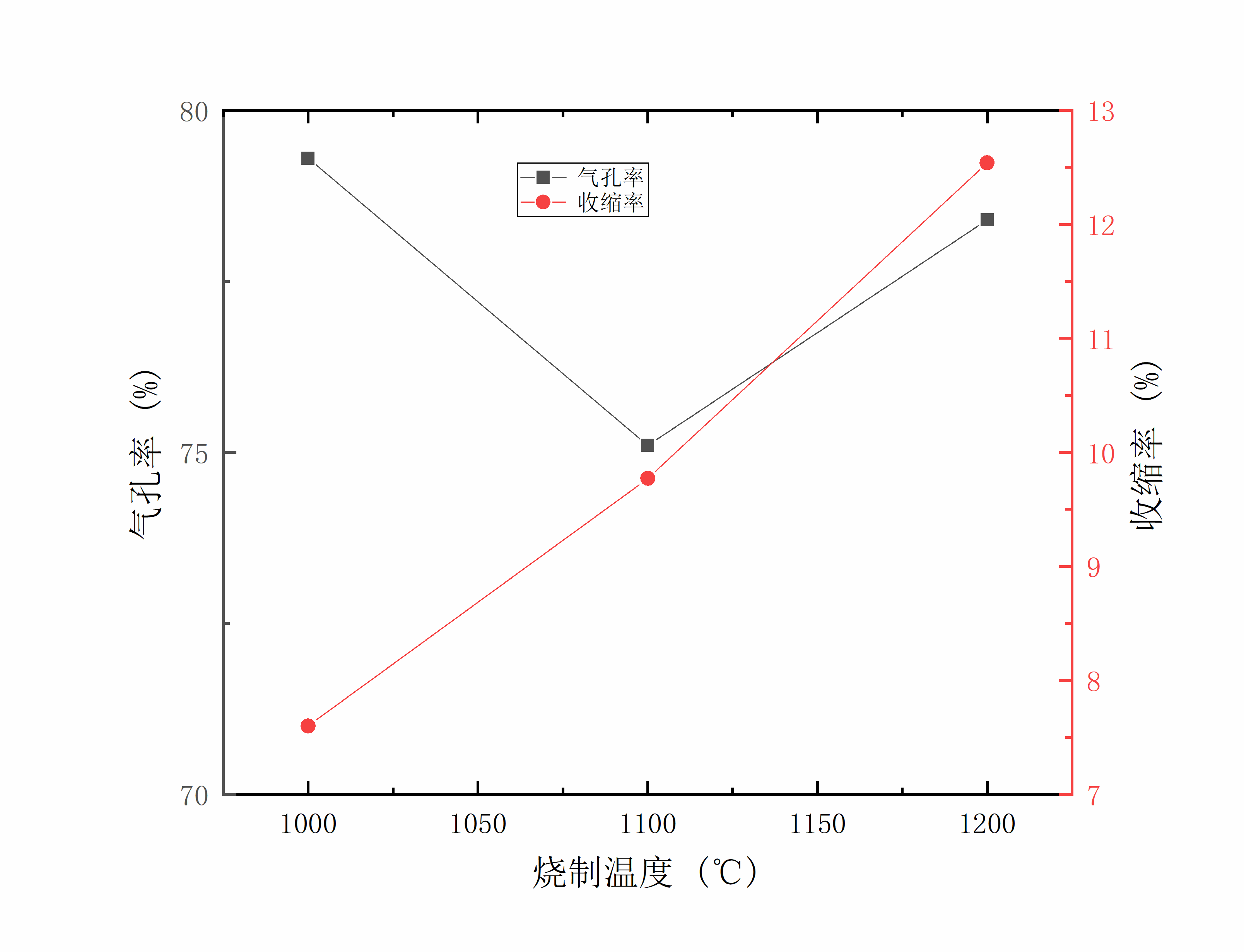

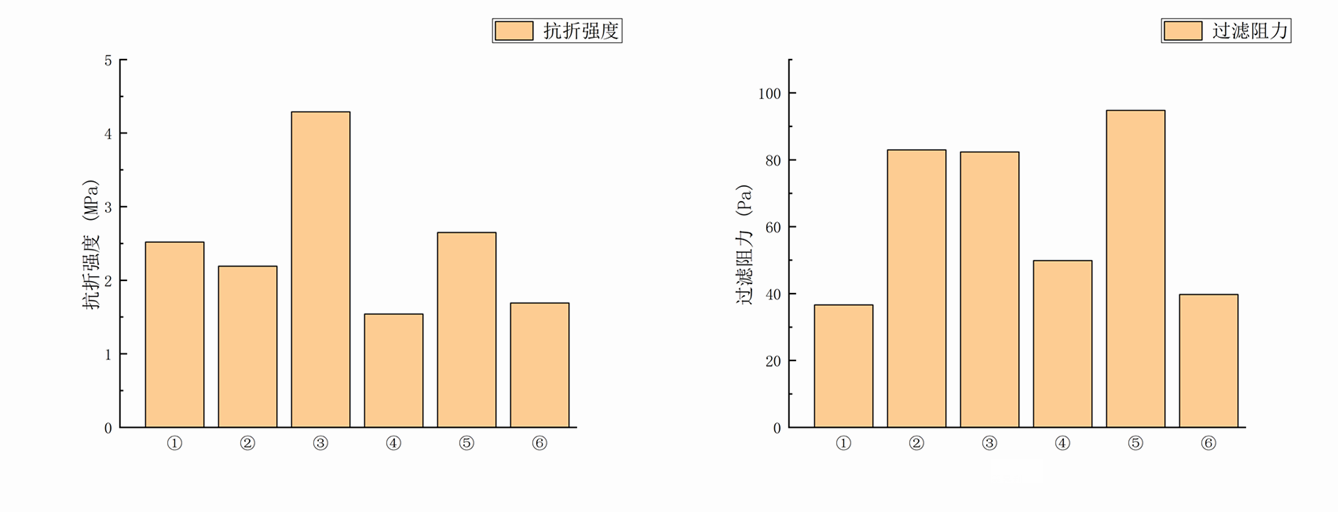

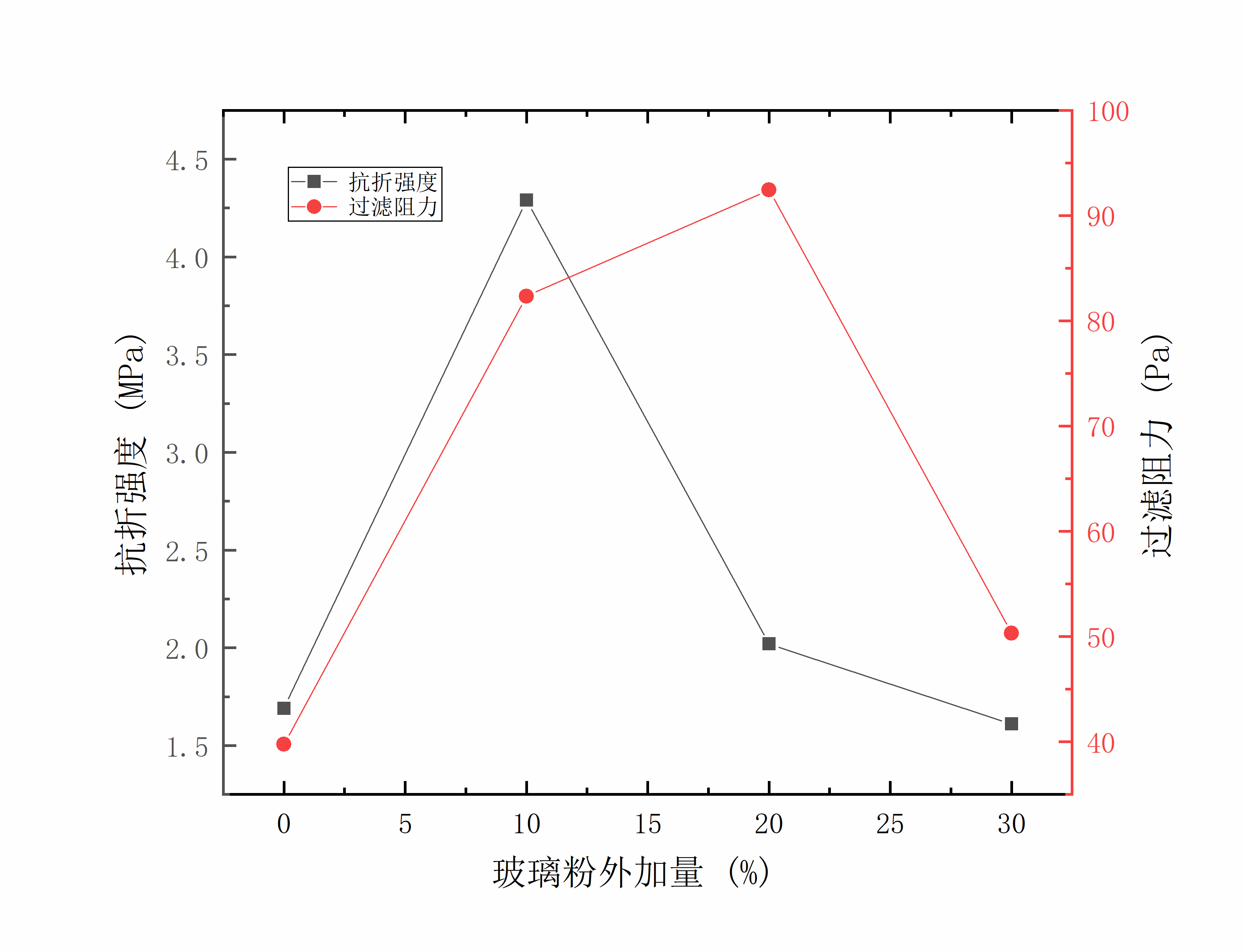

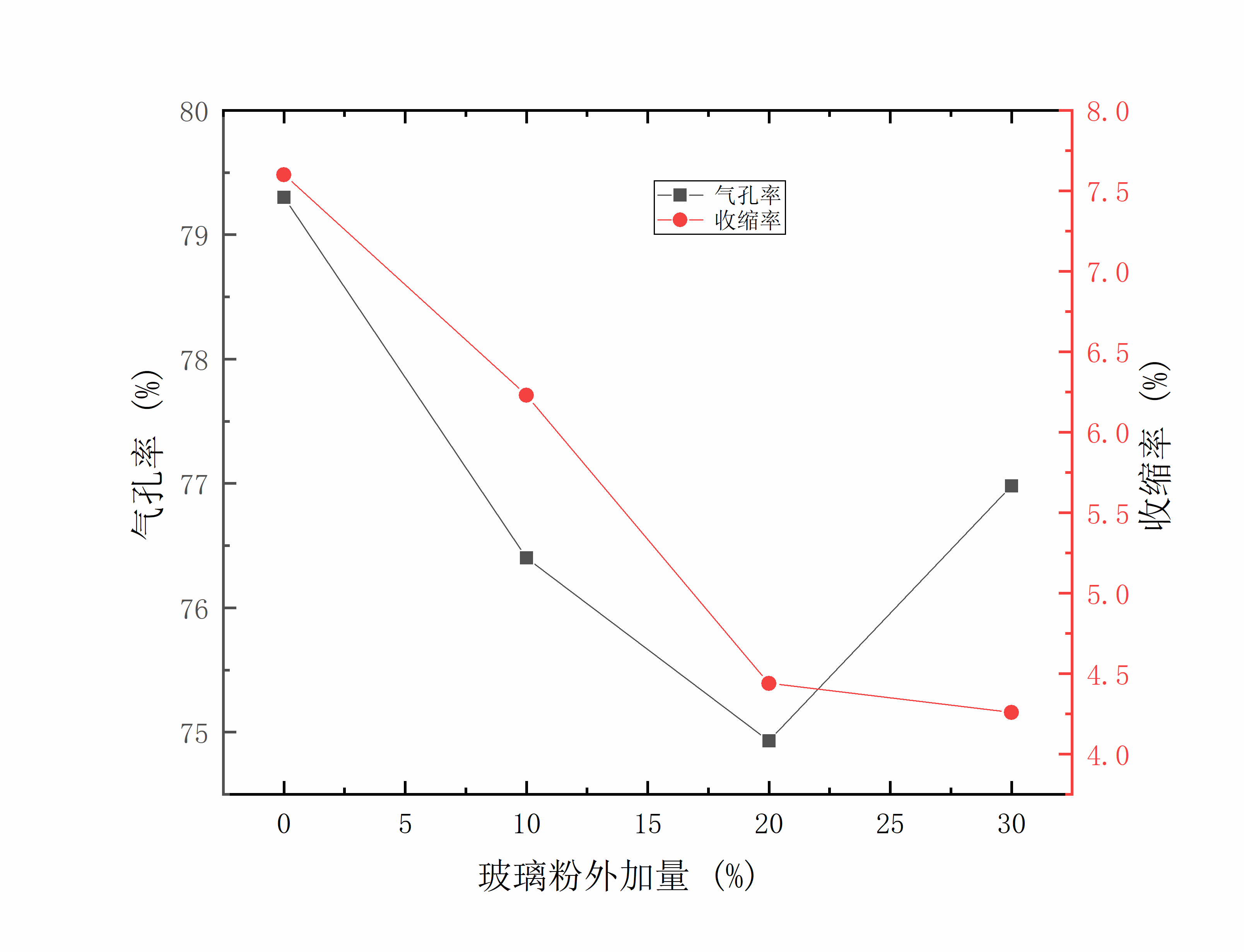

本课题选用廉价易得的氧化铝纤维制作纤维基陶瓷过滤材料,并引入铝溶胶作为无机粘结剂,添加玻璃粉为烧结助剂,使用“真空抽滤法”成型,可有效避免材料在工业化应用中“碱金属中毒”问题,同时增强过滤材料的强度、抗热震等性能。通过改变烧结助剂添加量、处理方式、烧结温度,探究它们对材料抗折强度、过滤阻力、显气孔率、收缩率等性能的影响。

外加10%左右玻璃粉为烧结助剂,高速搅拌,并在1000℃下烧制时,材料具有较好的强度、较低的过滤阻力、理想的气孔率和收缩率,相应的数据分别为:4.29MPa,82.34Pa,76.4%,6.23%。

关键词:烟气过滤 纤维陶瓷 玻璃粉 气固分离

Preparation of low-resistance high-temperature gas filter material

Abstract

At present, domestic environmental protection policies are becoming more and more strict, and the control of air pollution has become a hot spot in society. Particles are the primary culprit in polluting the atmosphere. In this context, high-energy, high-emissions companies must focus on the research and efficient use of high-temperature gas filtration materials and equipment in order to achieve “ultra-low emission” standards. In the field of direct flue gas filtration, porous ceramic materials have always been the focus of the scientific community and enterprises, with high filtration efficiency, low equipment investment, and avoiding secondary pollution, which are the advantages of this material. Conventional porous ceramic materials generally have shortcomings such as low strength and poor thermal shock resistance. The ceramic fiber is used as the material matrix, and the inorganic binder is added to prepare the fiber-based ceramic filter material, which is resistant to acid and alkali corrosion, high in strength and good in thermal shock resistance.

This topic selects cheap and easy-to-obtain alumina fiber to make fiber-based ceramic filter material, and introduces aluminum sol as inorganic binder, adds glass powder as sintering aid, and uses "vacuum suction filtration" to form, which can effectively avoid material industrialization. The application of "alkali metal poisoning" problem, while enhancing the strength of the filter material, thermal shock resistance and other properties. By changing the amount of sintering aid added, treatment method and sintering temperature, the effects of their properties on the flexural strength, filtration resistance, apparent porosity and shrinkage of the materials were investigated.

Adding about 10% glass powder as sintering aids, stirring at high speed and sintering at 1000 ℃, the material has better strength, lower filtration resistance, ideal porosity and shrinkage. The corresponding data are 4.29 MPa, 82.34 Pa, 76.4% and 6.23%.

Key Words: Flue gas filtration;Ceramic fiber;Glass powder;Gas-solid separation

目 录

摘 要 I

Abstract II

第一章 绪论 1

1.1除尘技术背景 1

1.1.1高温气体来源 2

1.1.2高温气体除尘特点 2

1.1.3高温气体除尘技术 2

1.2 高温烟气直接净化技术 3

1.3 高温陶瓷过滤器 3

1.3.1过滤机制 3

1.3.2高温陶瓷过滤器的分类 4

1.3.3 应该具有的特点 5

1.3.4国内外研究进展 5

1.3.5过滤效率影响因素 5

1.4陶瓷过滤材料的制备方法 6

1.4.1多孔陶瓷材料 6

1.4.2陶瓷纤维过滤材料 6

1.5 课题研究 7

1.5.1课题背景 7

1.5.2课题研究内容 8

1.5.3应用前景 8

第二章 材料的制备与测试 9

2.1 实验原料 9

2.2 实验设备 9

2.3 材料制备工艺 9

2.4 材料测试方法 11

2.4.1 体积收缩率 11

2.4.2 过滤阻力 11

2.4.3 气孔率 11

2.4.4抗折强度 12

第三章 实验结果与分析 13

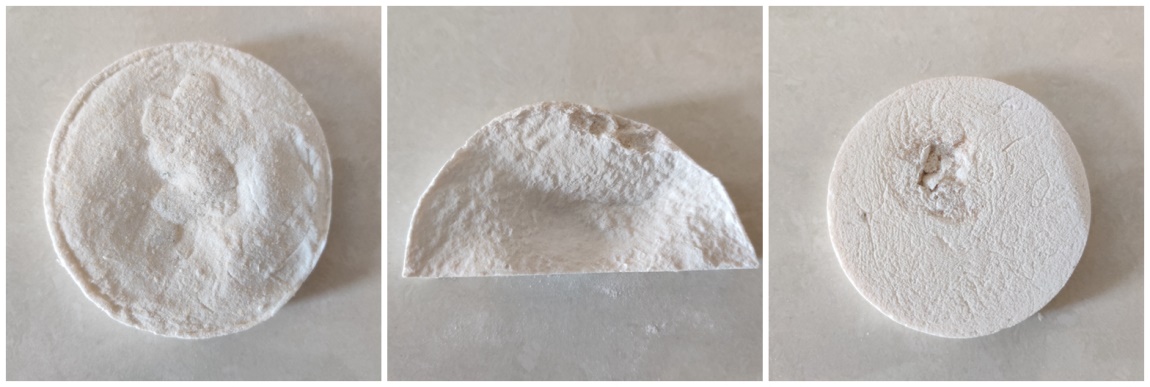

3.1 纯氧化铝纤维样品分析 13

3.2 14

3.3玻璃粉添加量对样品性能的影响 16

3.4烧制温度对样品性能的影响 18

第四章 结论与展望 20

4.1 结论 20

4.2 展望 20

参考文献 21

致 谢 23

第一章 绪论

近几年,我国对生态污染问题加大管控力度,企业效益不影响,同时响应国家“绿水青山,就是金山银山”口号,已被众多企业列入发展目标之一。譬如钢铁、水泥、化工、电力等行业,绝大部分企业在冶炼、焚烧、发电、燃煤等过程中均产生高温烟气,高温烟气的净化已成为它们实现“节能减排”的重要技术攻关课题。

高温烟气不加净化直接排出导致的烟尘污染,是大气污染的主要来源。前些年,大气污染在我国环境污染问题中尤为严重,雾霾、PM2.5等问题一直困扰着人类的生活和其他生物生存环境的发展。

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。