环氧树脂功能化改性气相法白炭黑工艺研究毕业论文

2020-05-15 22:29:43

摘 要

本文采用原位改性技术用环氧树脂来改性纳米SiO2,并将改性后的纳米SiO2和树脂混合液作为母料添加到纯环氧树脂中对其进行增韧。改性主要通过纳米SiO2表面的硅醇基(Si-OH)和环氧树脂的环氧基在一定条件下发生化学键接反应来实现。后期利用冲击测试、拉伸测试、傅里叶红外光谱仪(FTIR)、动态热机械分析(DMTA)等手段来对改性产物的性能和结构进行表征研究。实验中根据各项表征结果和力学性能测试数据来研究不同的改性条件对环氧树脂物理机械性能的具体影响。实验测试结果显示,改性纳米 SiO2的加入量1%为增韧环氧树脂的最佳比例,其冲击强度和拉伸模量存在最大值,分别增长了约37%和16.4%,而且玻璃化温度比纯环氧提高了23℃;当加入量为1.5%时,拉伸强度到达最大值44.38 MPa,增长5.6%,断裂伸长率也到达最大值,增长了3.5%。

关键词:环氧树脂 表面功能化 纳米SiO2 原位改性

Functional modification of Fumed silica with

Epoxy resin

Abstract

In this paper, the in-situ modification was performed with epoxy resin on the surface of fumed silica, then the mixture of modified nano-scaled silica and epoxy resin was added to the neat epoxy to toughen it. The modification was achieved by the chemical reaction of the silanol group of silica and the oxirane ring of epoxy compounds. The polymer structure and property were studied by means of Impact Test、Tensile Test 、FTIR and DMTA. We could study the different modification conditions on the physical and mechanical properties of epoxy resin compounds according to the results of the characterization and mechanical properties test data .

The results showed that when the additive amount of modified nano-scaled silica was 1%, the impact strength and tensile modulus reached maximum and increased by 37% and 16.4%,the glass transition temperature also reached the peak of 145℃ which was increased by 23℃; When the additive amount was 1.5%, the tensile strength reached the maximum value of 44.38 MPa, increased by 5.6%, the elongation at break also reached the maximum value, increased by 3.5%.

Key Words: Epoxy resin; Surface functionalization; Nano-silica; In-situ modification

目录

摘要............................................................................... .............Ⅰ

Abstract.......................................................................................Ⅱ

第一章 绪论............................................................................... . 1

1.1环氧树脂的定义及发展历程....................................1

1.2环氧树脂的结构特性及其应用概况..............................1

1.3环氧树脂的改性研究..........................................2

1.4纳米二氧化硅增韧环氧树脂的研究..............................3

1.5本实验内容简介及目的........................................4

第二章 实验部分....................................................................... . .6

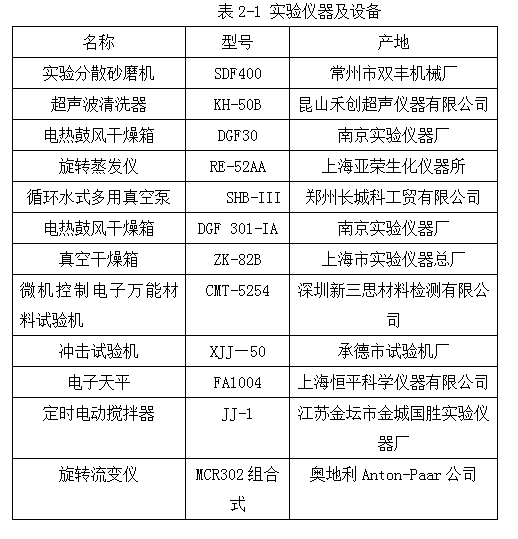

2.1 实验仪器及设备.................................................................... 6

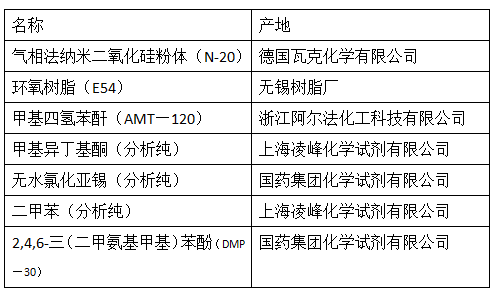

2.2 实验原料及药品.................................................................... 6

2.3 环氧树脂功能化改性纳米二氧化硅工艺流程................................. 7

2.4 环氧树脂功能化改性纳米二氧化硅实验...................................... 7

2.5 固化实验........................................................................... 10

2.6 力学性能测试实验................................................................10

2.7动态热机械分析(DMTA)测试................................................... 10

2.8傅里叶红外光谱仪(FTIR)测试............................................ .... 12

2.9热重分析(TG)测试........................................................... .... 12

第三章 结果与讨论............................................................... ......13

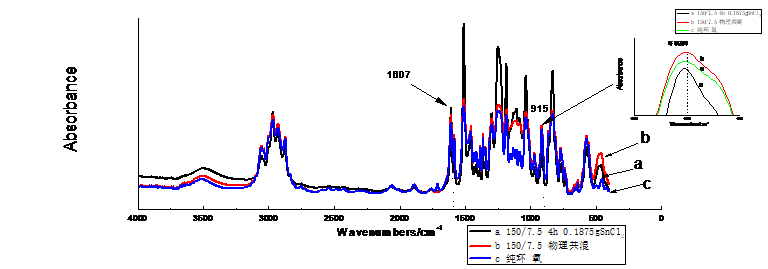

3.1 红外光谱分析......................................................................13

3.2 工艺条件对改性反应的影响....................................................14 3.3热重分析(TG)结果.................................................................16

3.4改性树脂动态机械热分析........................................................17

3.5 力学性能测试结果................................................................20

第四章 全文主要结论............................................................... ...23

4.1 主要结论......................................................................... ..23

4.2 研究工作不足及展望........................................................... .23

参考文献.................................................................................. . .24

致谢.................................................................................. . .... ...26

第一章 绪 论

1.1 环氧树脂的定义及发展历程

1.1.1 定义

环氧树脂(Epoxy Resin)是指有2个或以上数量的环氧基,主体结构为脂肪族或芳香族等有机化合物并且能通过分子结构中环氧基团的化学反应形成热固性材料的高分子低聚体(Oligomer)[12]。

1.1.2 发展历程

相关图片展示:

课题毕业论文、开题报告、任务书、外文翻译、程序设计、图纸设计等资料可联系客服协助查找。